Automatic detection load axle

A technology for automatic detection and load capacity, applied in the field of motor vehicle axles, can solve the problems of inability to determine the weight of loaded goods in time, no automatic detection of load capacity, insufficient load capacity, etc., to avoid insufficient or overloaded loading capacity, safety The effect of no impact, easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

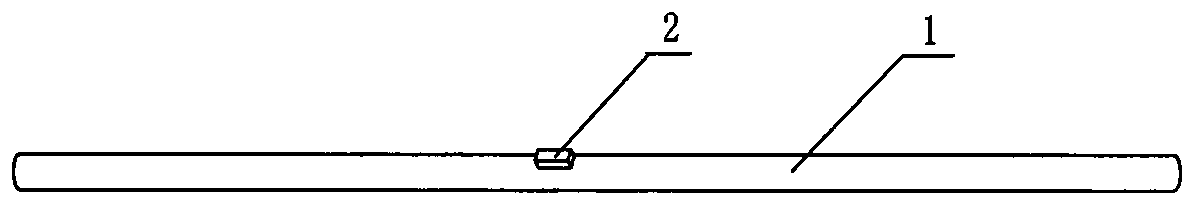

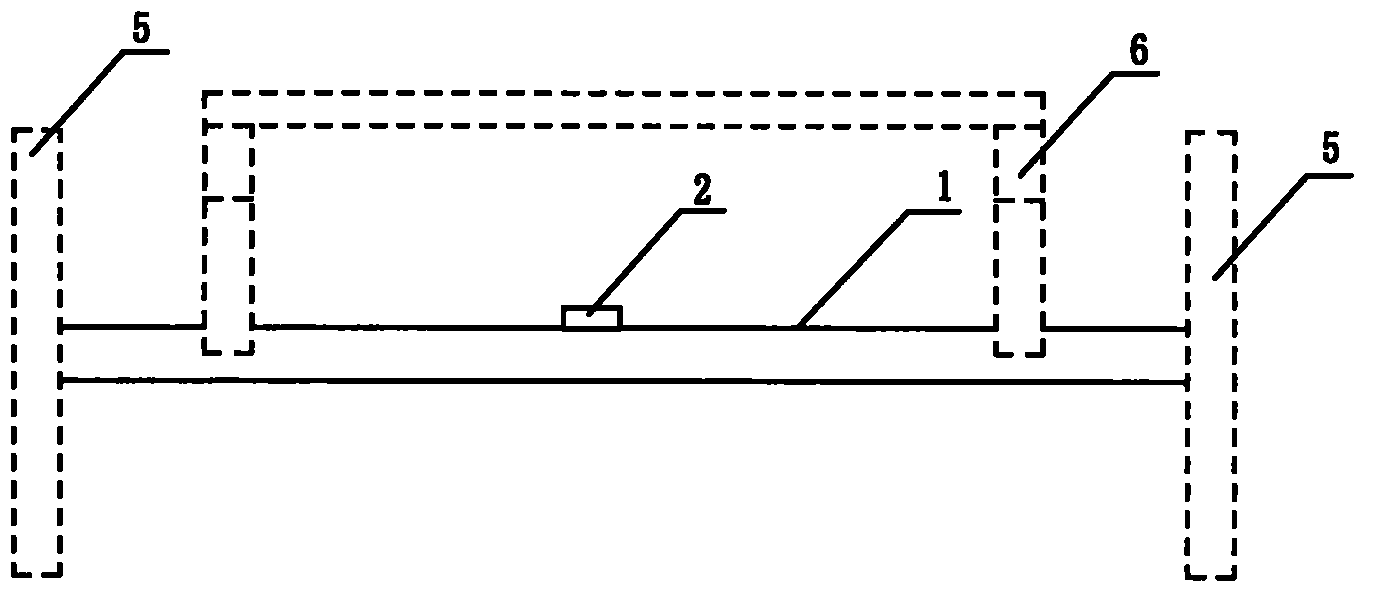

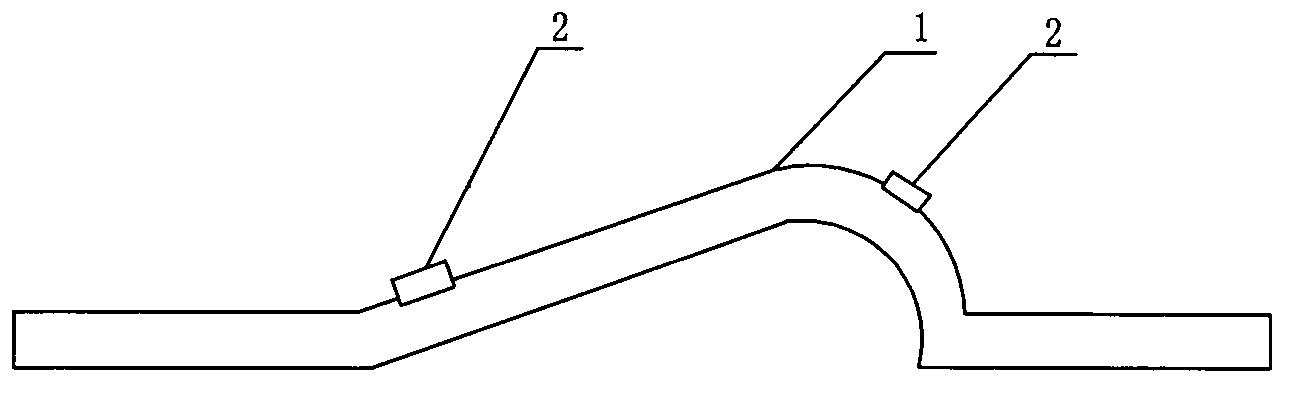

[0022] The present invention comprises an axle body 1, and one or two force sensors 2 are fixedly installed in the deformation zone of the axle body 1, such as figure 1 , 3 shown. The deformation zone of each axle body 1 is usually concentrated between the two points in contact with the vehicle frame 6. Therefore, when a force sensor 2 is installed on the axle body 1, its installation position is just close to the midpoint of the deformation zone of the axle body 1. ; When two force sensors 2 are installed on the axle body 1, the two force sensors 2 are just close to the two ends of the deformation zone of the axle body 1 respectively, as figure 2 , 4 shown.

[0023] The force sensor 2 is composed of a curved beam elastic body and a plurality of resistance strain gauges, the middle area of the elastic body is the deformation area 201, and the two ends are the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com