Lower bearing-type wheel rail operation mechanism of electric railway empty coach

A technology of operating mechanism and airbus, which is applied in transportation and packaging, railway car body parts, and prevention of railway derailment, etc. It can solve the problems of urban development, heavy passenger car box, high manufacturing cost, etc., and achieve low cost and exquisite structure Simple, high safety factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

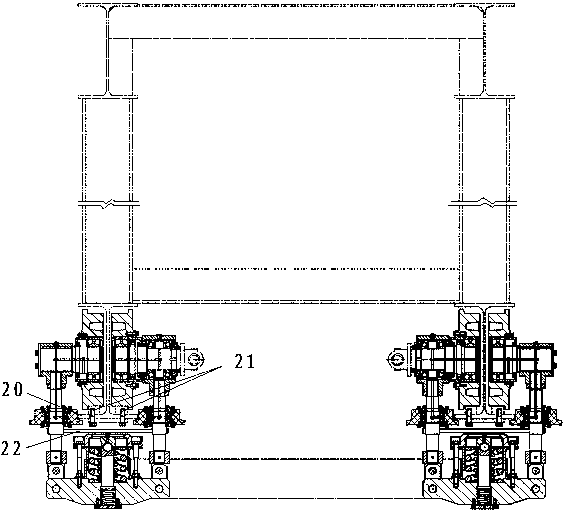

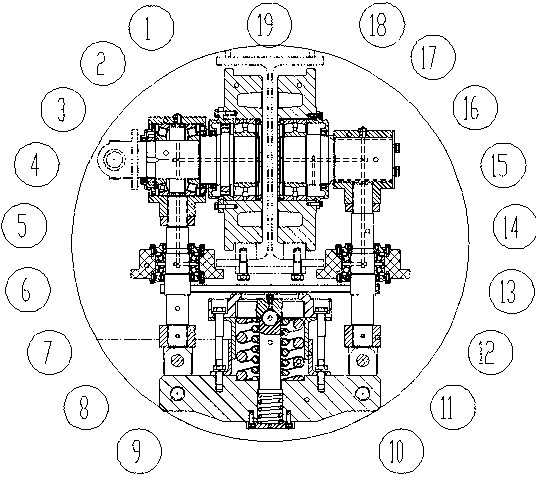

[0025] Attached below figure 1 , 2 The present invention is described in detail:

[0026] An electric track airbus under-supporting wheel-rail running mechanism, the running mechanism includes at least four running mechanism units,

[0027] Each running mechanism unit comprises a driving wheel 1 and a passive wheel 19 on the opposite side of the driving wheel 1, the driving wheel 1 and the driven wheel 19 are rollingly connected in the seamless track 20, and the lower edge of the seamless track 20 is opposite to A pair of rail height adjustment devices 21 are arranged at the position of the driving wheel 1 and the passive wheel 19;

[0028] A load-bearing joist 10 and a load-bearing frame girder 12 are arranged at the lower part of the operating mechanism unit, a guide rod 14 is arranged on the load-bearing joist 10, a steel ball 15 is arranged at the upper end of the guide rod 14, and a steel ball 15 is arranged at the upper end of the guide rod 14. Combined cylindrical he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com