High-sensitivity piezoelectric ceramic material, and preparation method and application thereof

A technology of piezoelectric ceramics and raw materials, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of low sensitivity and poor stability , The performance can not be very good to meet the problems of the whole electronic machine, to achieve the effect of good sensitivity, long-term work performance and stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

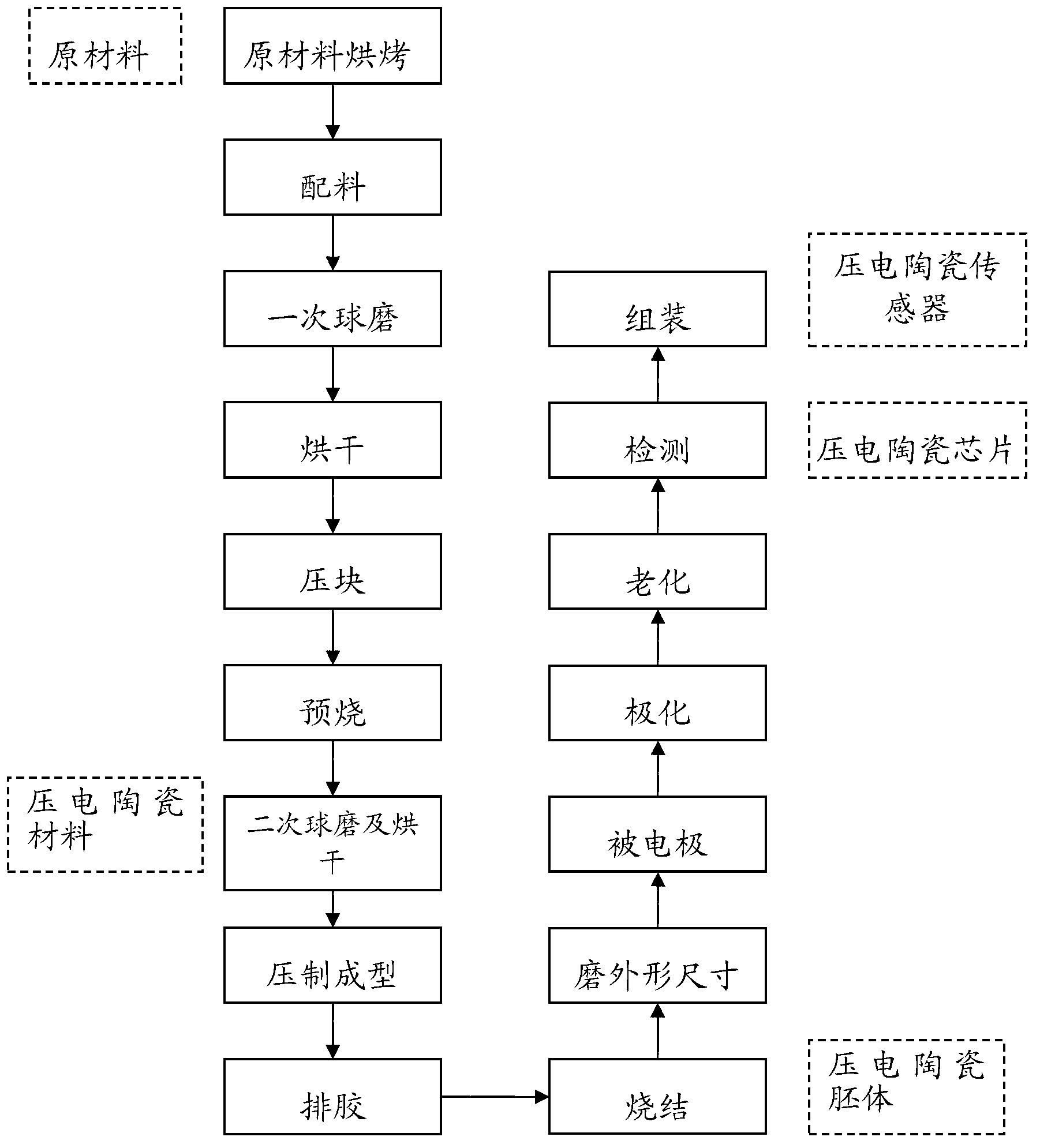

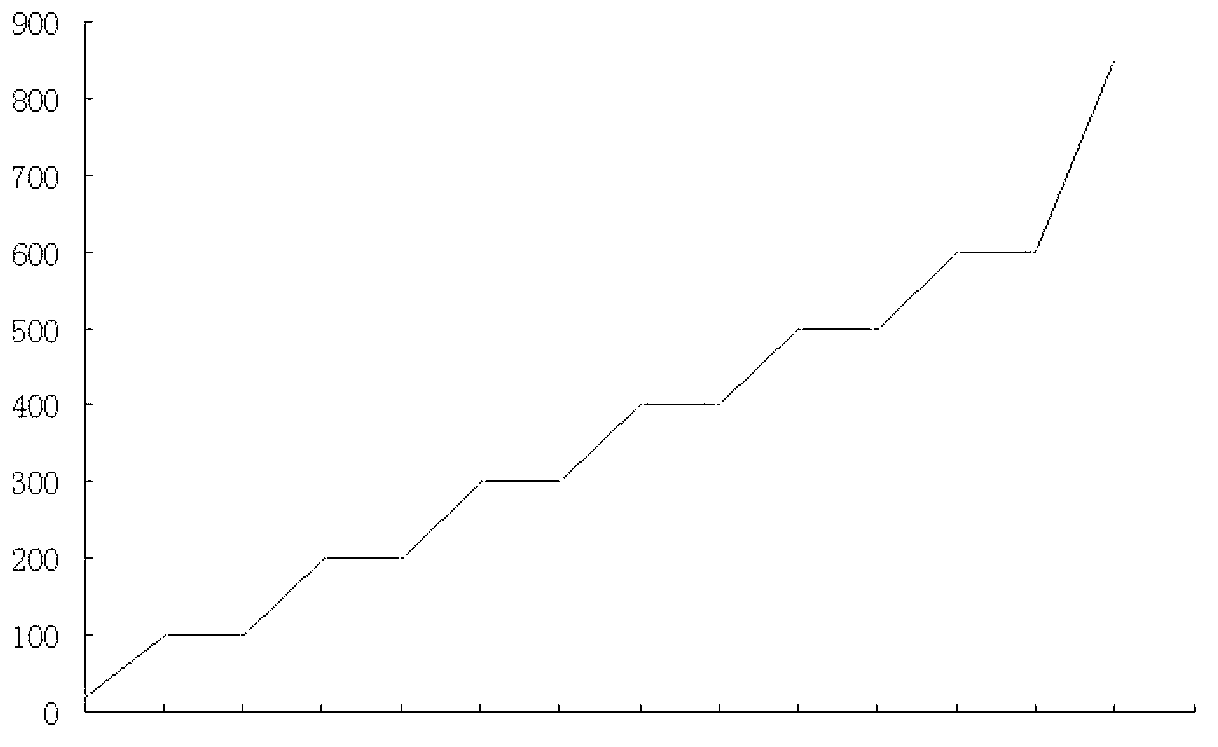

Method used

Image

Examples

specific Embodiment approach

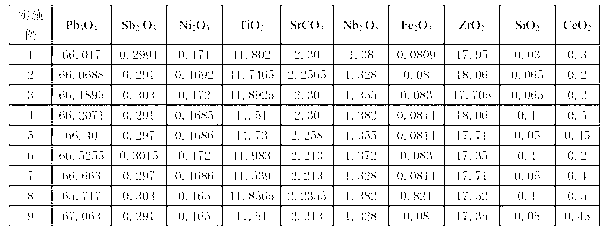

[0061] The piezoelectric ceramic material formulation involved in the present invention consists of core components and additional components, wherein the core components include, Pb 3 o 4 , SrCO 3 , Sb 2 o 3 , Nb 2 o 5 , Ni 2 o 3 , Fe 2 o 3 ,TiO 2 , ZrO 2 ; in the core component, and add the following additional component, SiO 2 , CeO 2 , the content of the additional components is added based on the total amount of the core components. The sum of the proportions of each component of the core component is 100%; based on the sum of the weight of the core components, a certain proportion of additional components are added, and the proportion of the added components is calculated based on the sum of the weight of the core components.

[0062] Among them, the core component (total ratio): Pb 3 o 4 : 65.07%-67.73%, SrCO 3 : 2.213%-2.3%, Sb 2 o 3 : 0.291%-0.303%, Nb 2 o 5 : 1.328%-1.382%, Ni 2 o 3 : 0.165%-0.172%, Fe 2 o 3 : 0.08%-0.083%, TiO 2 : 11.51%-11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com