A kind of composite material pile and its manufacturing method

A composite material and manufacturing method technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of inability to get rid of core material and cement-soil piles to bear vertical load together, core material is not economical, etc. Economic effect and promotion conditions, effect of improving carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

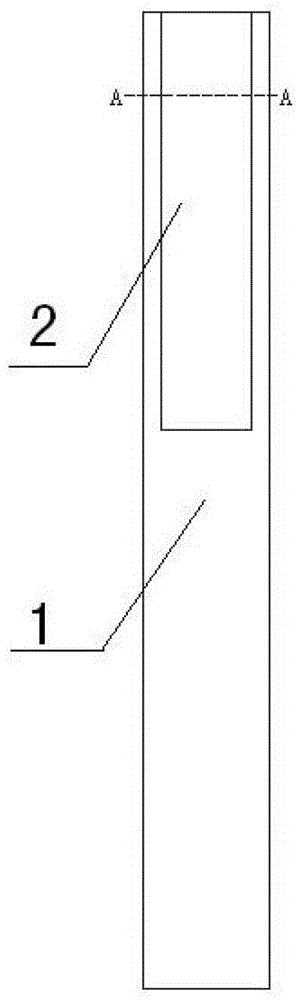

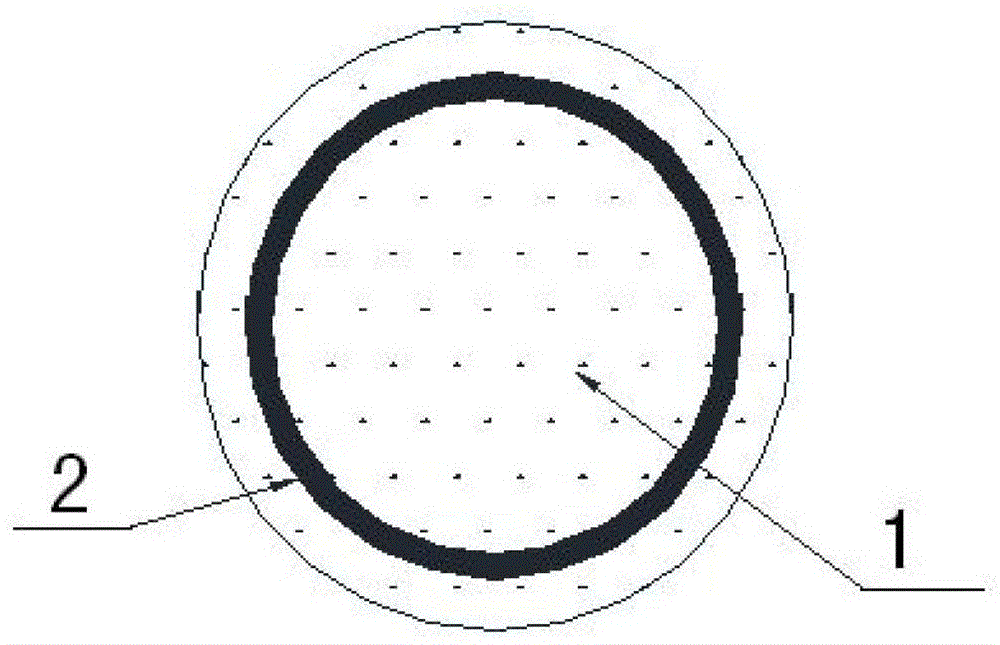

[0022] Such as figure 1 and figure 2 As shown, a composite material pile according to the embodiment of the present invention includes a cement-soil pile 1 , and a stiffening tube 2 is arranged inside the cement-soil pile 1 , and the stiffening tube 2 is arranged on the upper part of the cement-soil pile 1 . The material of the cement-soil pile 1 is cement-soil, and the cement content in the cement-soil is 15% and the water content is 40%.

[0023] The stiffening pipe 2 is a PE (polyethylene) pipe, HDPE (high density polyethylene) double-wall corrugated pipe, or a polyethylene winding pipe. Its advantages mainly include:

[0024] (1) It has excellent corrosion resistance and long service life. PE pipes can resist the corrosion of various chemical media. The chemical substances in the soil will not cause any degradation to the pipes. Under the condition of 20°C, the pipes can still maintain the minimum required strength (circumference) of 10MPa after 50 years. Polyethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com