The Construction Method of the Spiral Heat Pipe Annular Convex Rib Drainage and Grouting Bamboo Pile

A construction method and technology of bamboo piles, which are applied in sheet pile walls, soil protection, infrastructure engineering, etc., can solve the problems of large variation in bearing capacity, large environmental impact, and difficult construction, and achieve increased frictional resistance, increased The effect of large frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further understand the content of the present invention, the present invention is described in detail in conjunction with examples, and the following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

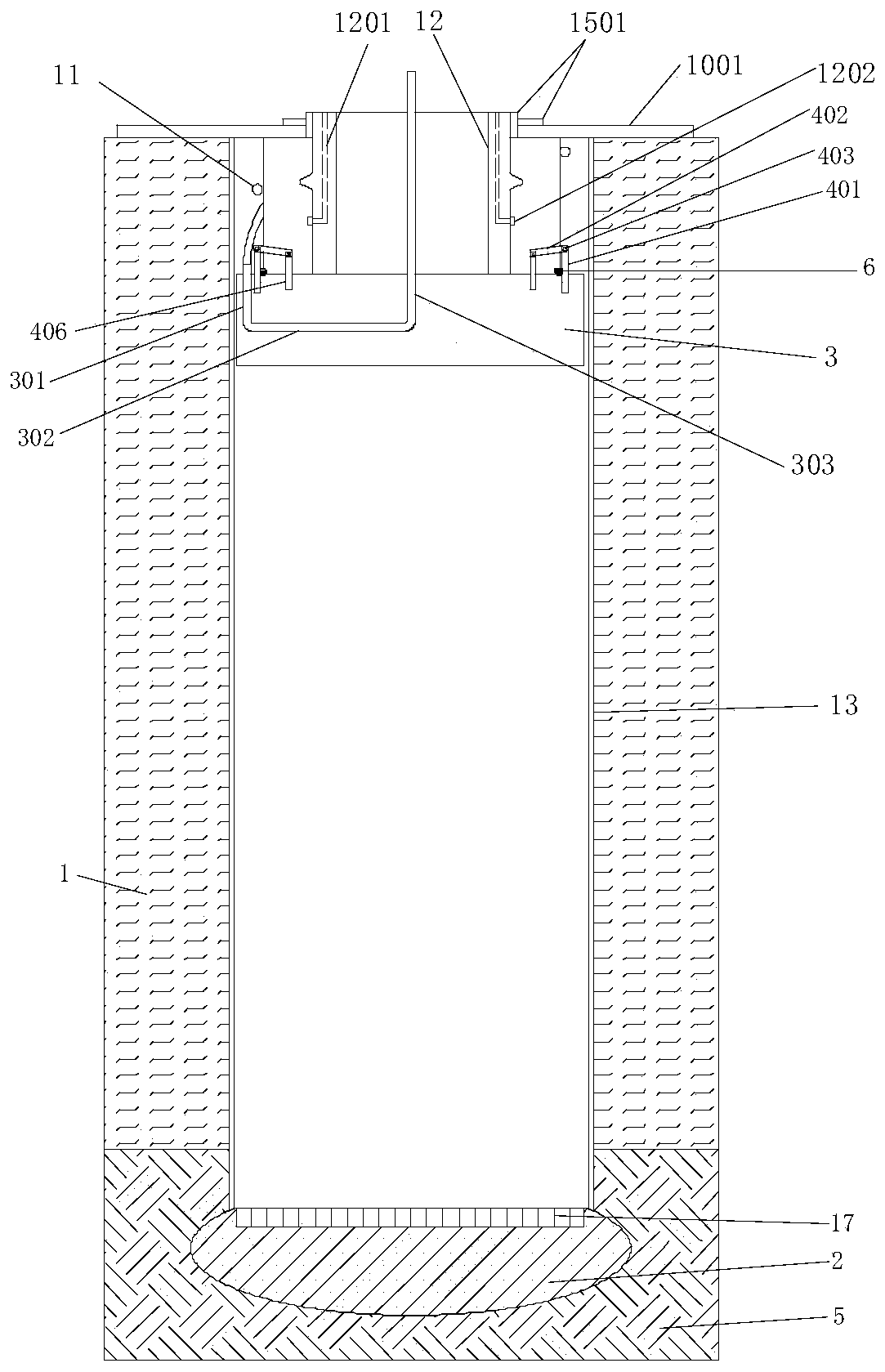

[0051] combined with figure 1 ~ attached Figure 7 , the construction method of the helical heat pipe ring-shaped convex rib that the present invention involves first draining water and then grouting the bamboo joint pile comprises the following construction steps:

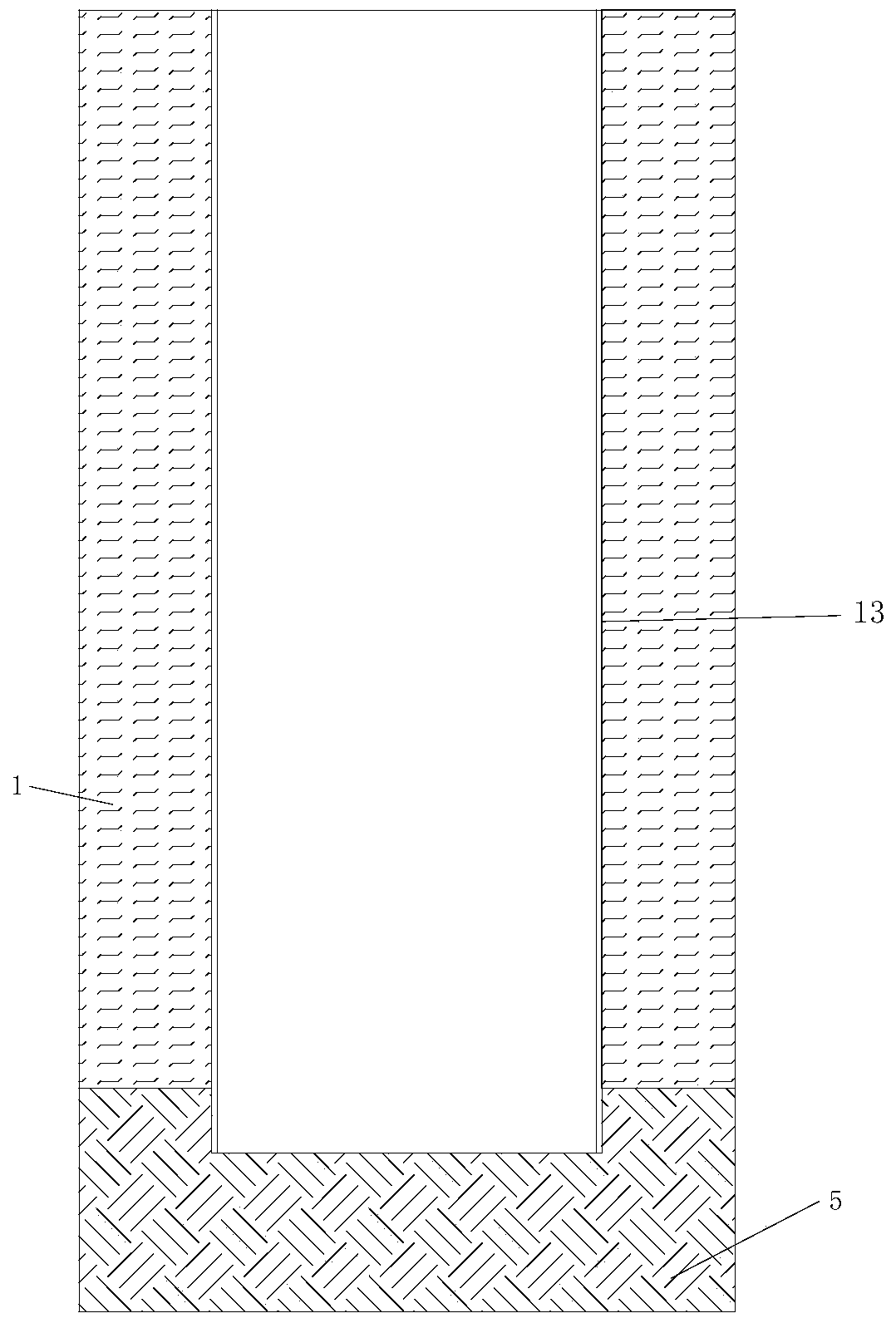

[0052] S1: Drive the steel casing into the designated position in the soft soil layer until the hard soil layer, and simultaneously use drilling equipment to form holes. figure 1 shown;

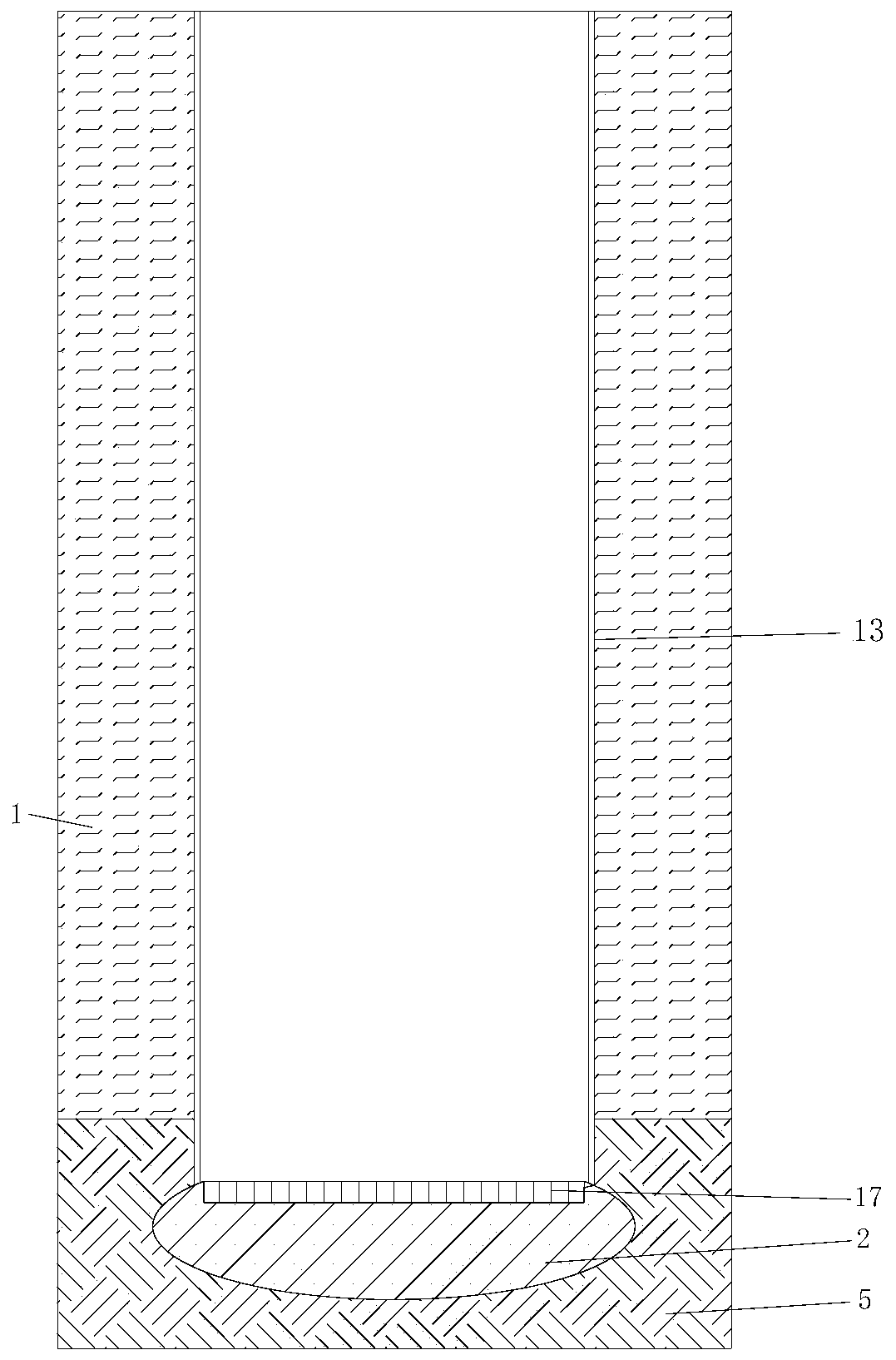

[0053] S2: Throw and fill gravel or building recycled materials at the bottom of the hole, use a rammer to form the bottom end of tamping and expansion, and fill the upper part with dry hard cement to form a bottom expansion leveling layer, if a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com