An easy-to-maintain coaxial mechanical gearbox

A mechanical gearbox, coaxial technology, applied in the field of gearboxes, can solve problems such as limited development space of forklifts, difficulty in shifting gears, troublesome replacement, etc., to solve the difficulty of replacing clutch parts, flexible and light shifting, and improve practical functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

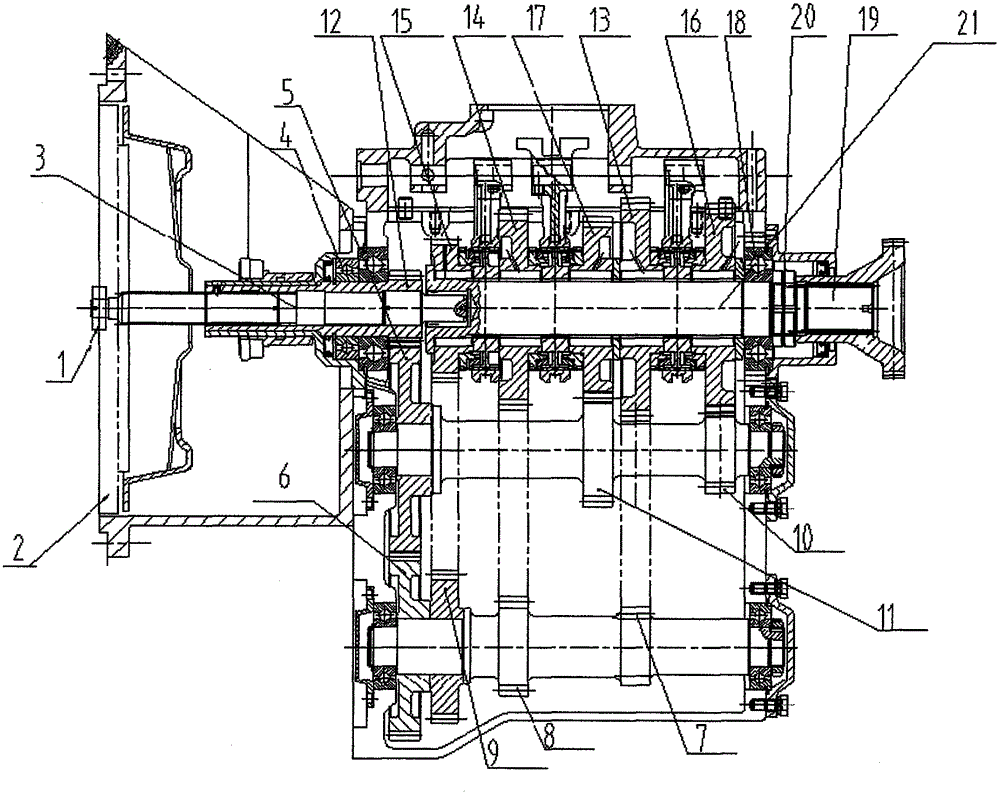

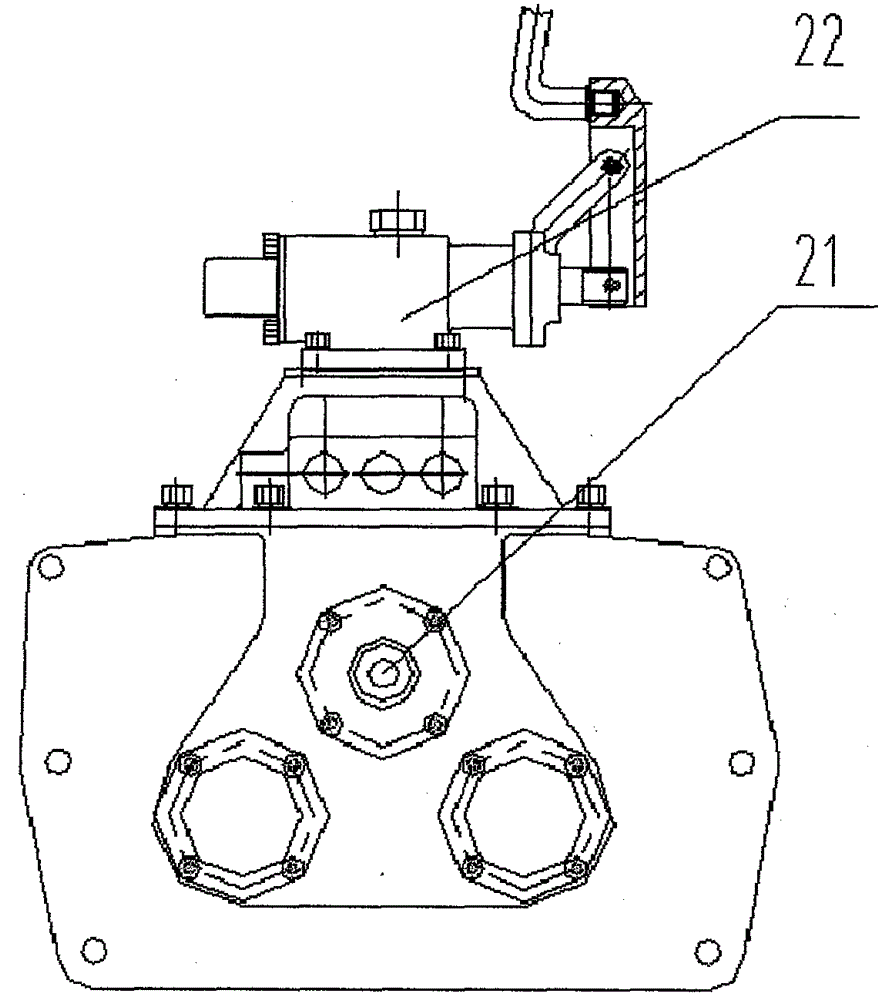

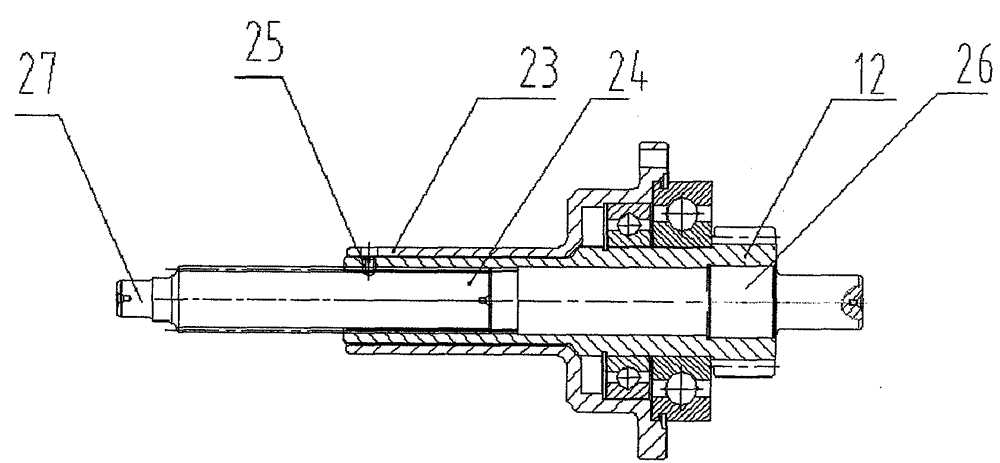

[0021] combine Figure 1-Figure 3 ;

[0022] The present invention can be directly connected with the engine clutch. The gearbox adopts a high-power double intermediate shaft structure, which is composed of four major sub-assemblies such as the power input shaft 3, the forward intermediate shaft, the reverse intermediate shaft and the output shaft 21. The input shaft gear meshes with the normally retreating and normally meshing gear 5 (acting as an idler gear at this time) and the normally advancing and normally meshing gear 6, and the power is input to the forward intermediate shaft subassembly, through the gear pair of the first gear and the second gear. The gear pair and the gear pair of the third forward gear are meshed with each other to achieve speed ratio of the first forward gear: 8.88, the speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com