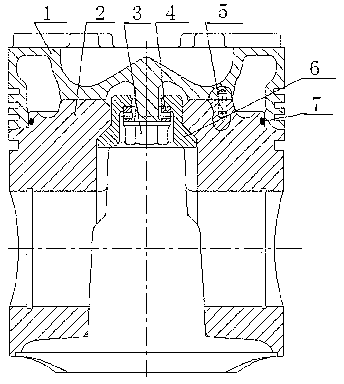

Steel crown and aluminium skirt piston

A technology of piston and steel top, applied in the field of steel top aluminum skirt piston, can solve the problems of low strength and high cost of piston, and achieve the effect of high strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Such as figure 1 As shown, the steel-top aluminum skirt piston includes piston top 1, piston skirt 2, pressure block 4 and bushing 6, and the bolt 3 between piston top 1 and piston skirt 2 is tightened with pressure block 4 through the bolt 3 of piston top 2 itself. The bushing 6 is arranged on the bolt 3 and the pressure block 4, the piston top 1 and the piston skirt 2 are connected with an elastic cylindrical pin 5, and an O-shaped sealing ring 7 is arranged between the piston top 1 and the piston skirt 2. The steel top aluminum skirt of the present invention The piston replaces the small-sized all-aluminum piston, which makes the cost lower and the strength higher, and can work continuously in the environment of burning heavy oil and high explosion pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com