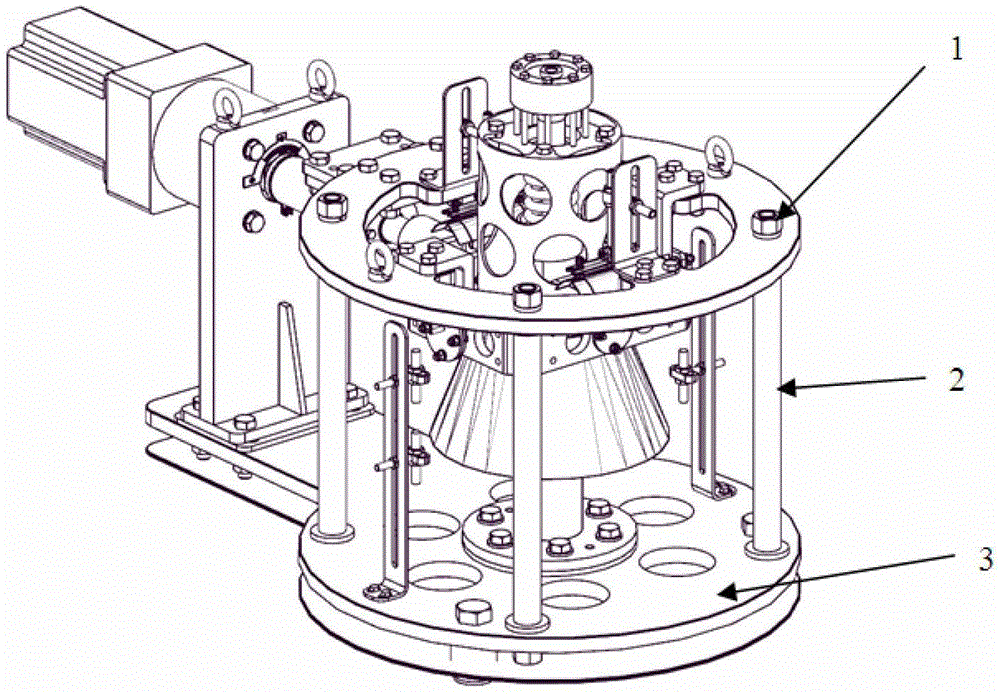

Performance testing apparatus of two-way rocking mechanism

A test device and performance technology, which is applied in the field of performance test devices of two-way rocking mechanisms to achieve the effects of high power density, small footprint and accurate force application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

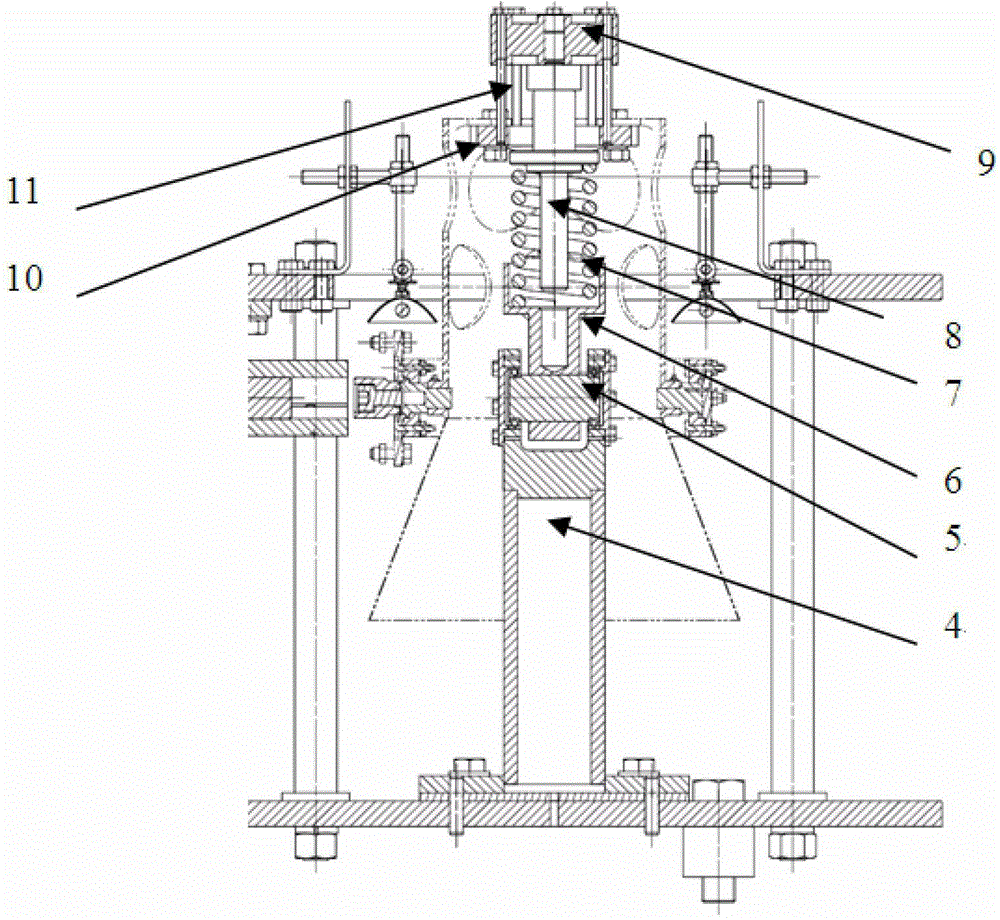

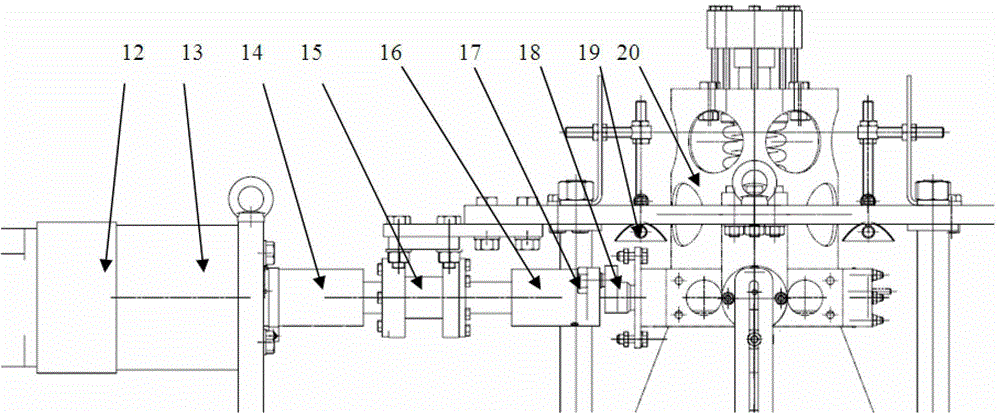

[0022] In the present invention, the overall structure of the swing test system is designed to have a degree of freedom of rotation in one direction, and the force applying structure is placed inside the swing mechanism and can swing around an axis coaxial with the rotation axis of the swing mechanism. It can meet the two-direction swing test of the swing mechanism by manually adjusting the reversing direction; the swing mechanism is driven by a stepping motor, and the rotating shaft of the swing mechanism is heated by a quartz infrared short-wave radiator. Its advantages are multiple functions, compact structure, high precision, good strength, convenient operation, safety and reliability.

[0023] One of the technical solutions of the present invention is to design the mechanical structure to have a degree of freedom of rotation in one direction, and then manually adjust the direction to increase the degree of freedom of rotation in the other direction to meet the requirements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com