Informationized cement production management system

A production management system, cement technology, applied in the direction of electrical program control, comprehensive factory control, etc., to achieve the effect of easy query, accurate and simple measurement operation process, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

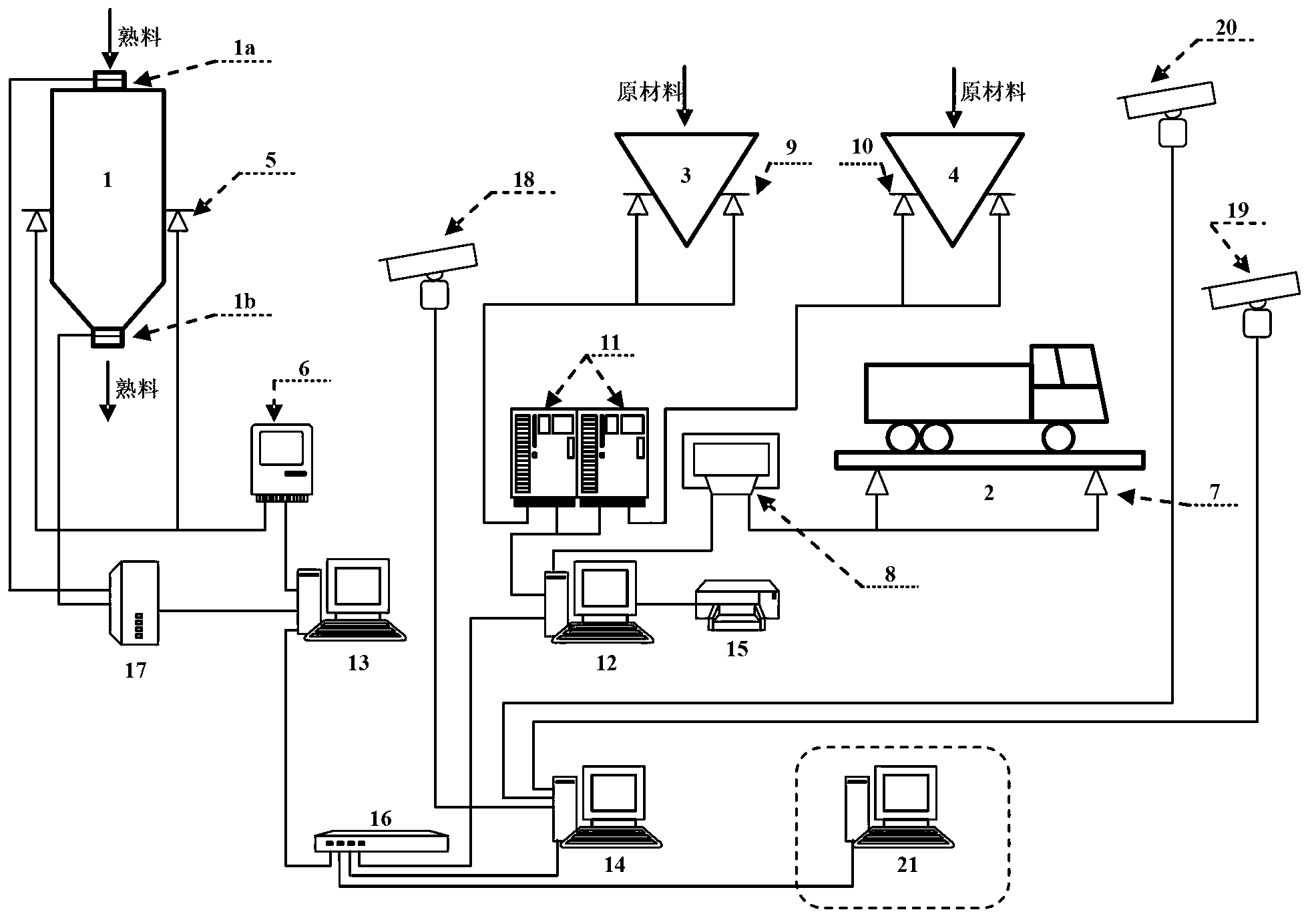

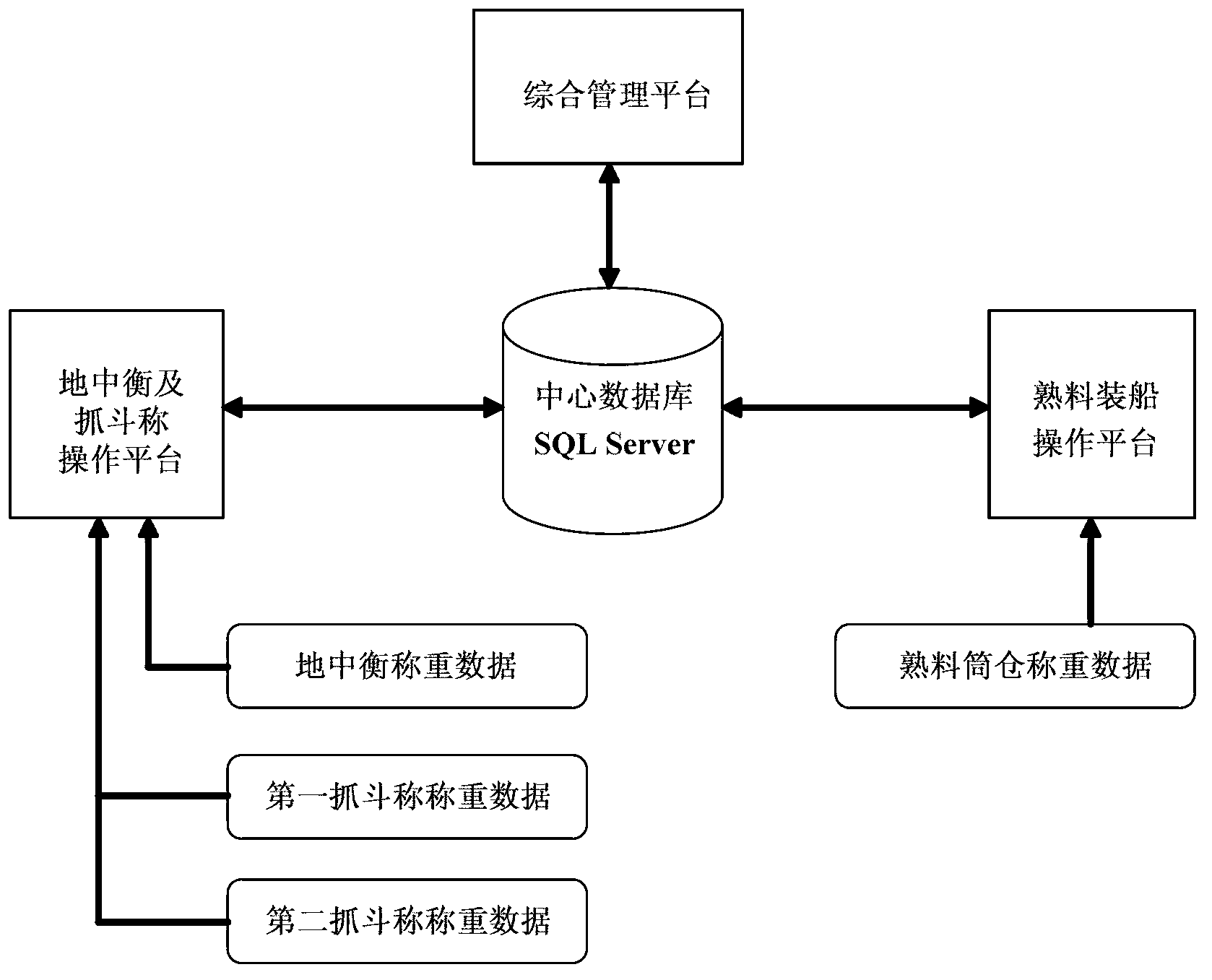

[0032] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 As shown, the informationized cement production management system of the present invention includes a clinker silo 1, a ground scale 2, a first grab scale 3, a second grab scale 4, and a clinker silo scale connected by a communication cable. Heavy sensor 5, clinker silo measurement and display instrument 6, ground balance weighing sensor 7, ground balance measurement and display instrument 8, first grab weighing sensor 9, second grab weighing sensor 10, grab Dou scale control cabinet 11, first operation station computer 12, second operation station computer 13, third operation station computer 14, printer 15, data switch 16, industrial computer 17, clinker silo monitoring camera 18, ground balance monitoring Video camera 19 and grab claim monitoring camera 20.

[0034] See figure 1 , The clinker silo 1 and the clin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com