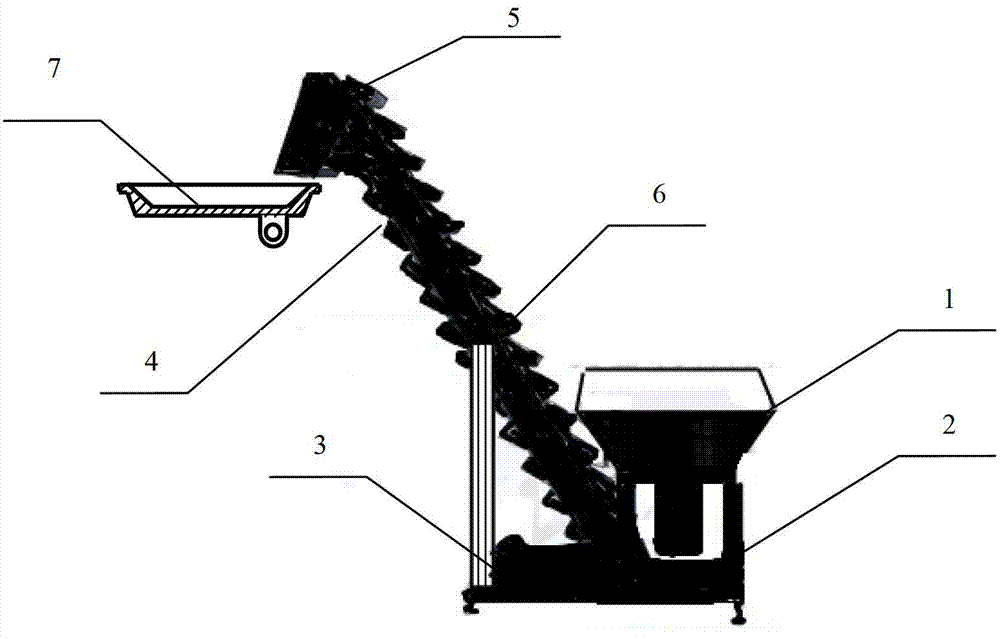

Flow-type high-precision, high-speed particle automatic counting device based on machine vision

A technology of automatic counting and machine vision, which is applied in the field of automatic counting of industrial components in large-scale production, can solve the problems of lack of self-learning and improvement ability, difficulty in satisfying real-time and accuracy, lack of adaptability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

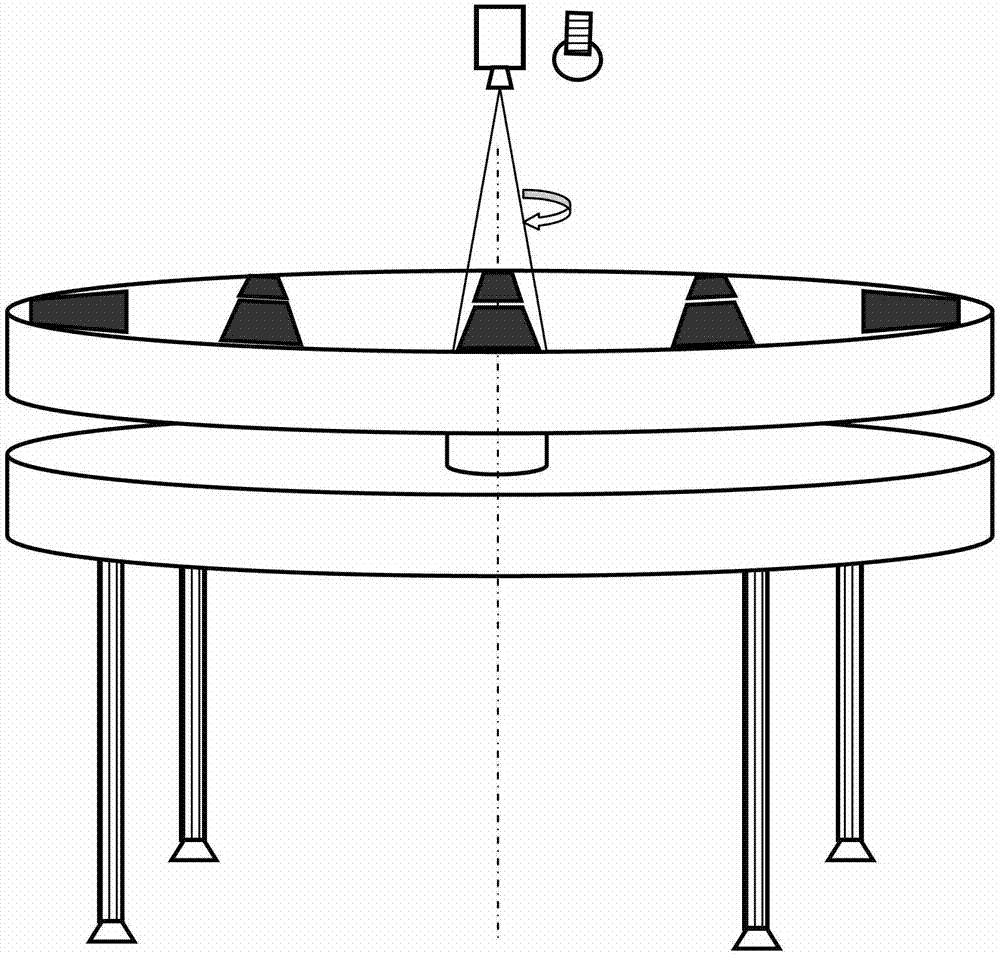

[0133] Embodiment 2, the rest is the same as Embodiment 1, the difference is that three cameras are respectively arranged on station 2, station 3 and station 4, so that the micro-vibration action on station 3 in embodiment 1 can be shared → Image capture action → micro-vibration action → image capture action → micro-vibration action → image capture action, that is, micro-vibration action at station 2 → image capture action, micro-vibration action at station 3 → image capture action, micro-vibration at station 4 Action → image capture action, image processing, automatic counting and majority voting calculations are still carried out in accordance with the original processing flow, so that the shared processing can effectively improve the recognition and counting efficiency of the detection pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com