Vessels including ribbed arched bottoms

A container, annular technology used in the manufacture of containers such as bottles or cans to solve problems such as collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

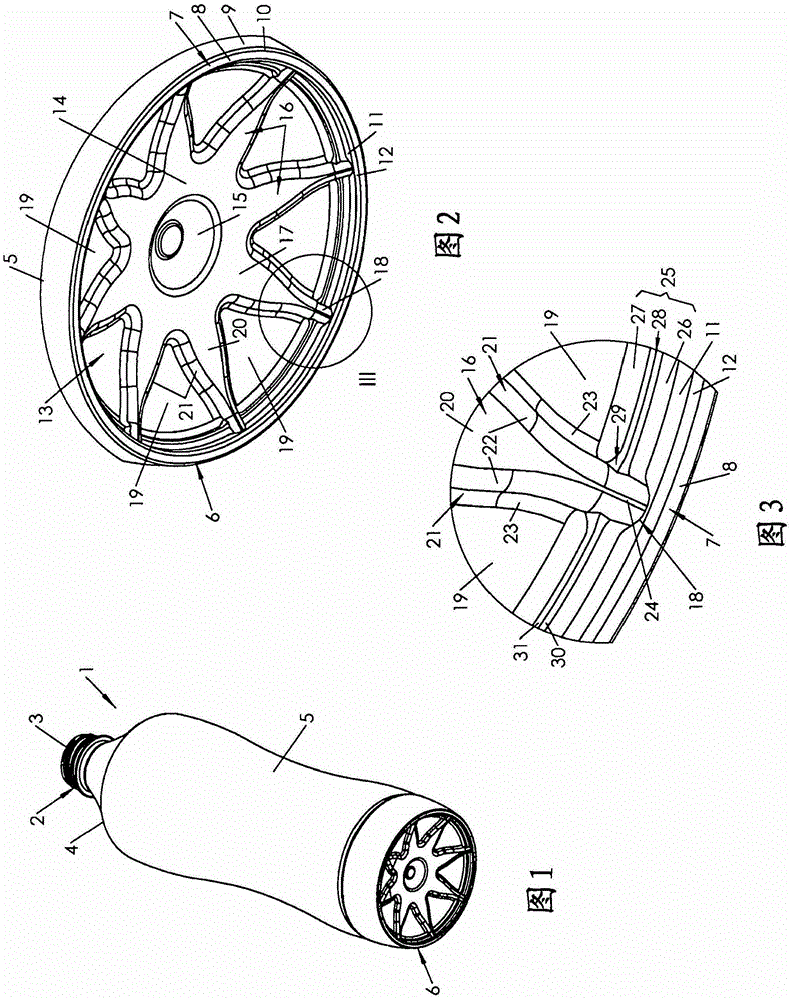

[0041] exist figure 1 Above shows a container 1 , in this case a bottle, made by stretch blow molding from a preform of thermoplastic material such as PET (polyethylene terephthalate).

[0042] The container 1 comprises a threaded neck 2 provided with a mouth 3 at the upper end. In the continuation of the neck 2, the container 1 comprises in its upper part a shoulder 4 which widens in the direction opposite the neck 2, the shoulder 4 being continued by a side wall or body 5 which The wall or body is generally in the shape of a cylinder of revolution around the main axis X of the container 1 .

[0043] The container 1 also includes a bottom 6 which extends at the lower end of the container 1 .

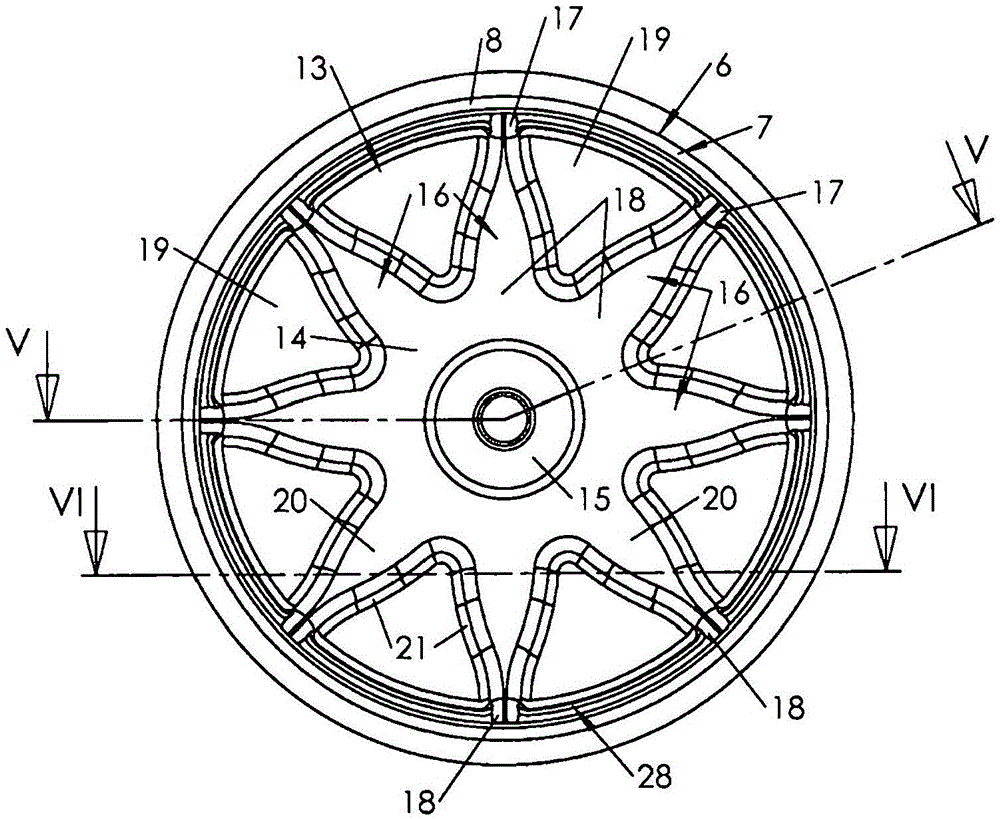

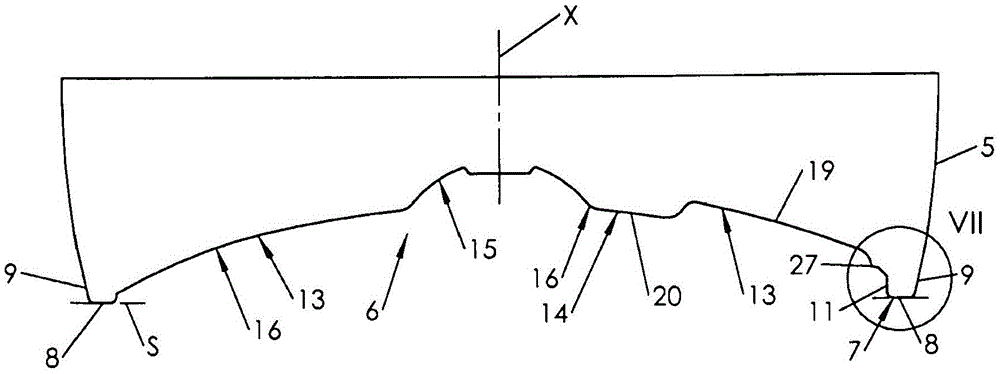

[0044] As can be seen on the accompanying drawings and more particularly in the Figure 5 , Figure 6 and Figure 7 As seen above, the bottom 6 comprises a base 7 in the form of a thin annular rim extending substantially axially in the prolongation of the body 5 . Base 7 terminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com