Method and apparatus for adjusting the concentration of acids or lyes

A technology for adjusting acid and lye, applied in the direction of mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of flow cross-section reduction, pressure loss, and outlet conduit can not achieve concentration, etc., to achieve pressure loss reduction , increase the flow resistance, the effect of uniform concentration distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

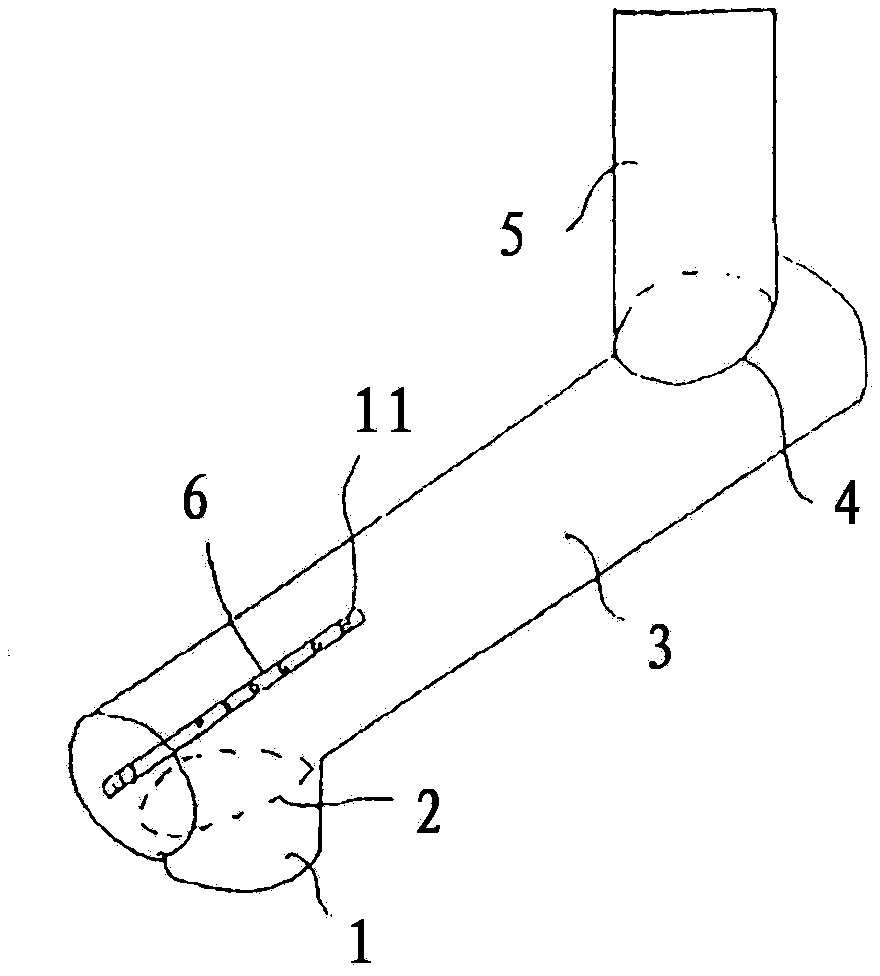

[0023] exist figure 1 An apparatus for concentration regulation of sulfuric acid as known in the prior art is shown in . The device comprises a supply conduit 1 for concentrated sulfuric acid, which is connected to an inlet 2 of a mixing chamber 3 . The mixing chamber 3 is arranged substantially at right angles to the supply duct 1 and has an outlet 4 at the end opposite the supply duct 1 , which is connected to a discharge duct 5 . The discharge duct 5 is also arranged substantially at right angles to the mixing chamber 3 and in substantially the same plane as the supply duct 1 .

[0024] In the end of the mixing chamber 3 adjacent to the inlet 2, a lance 6 with nozzle openings (so-called "black pipes") is arranged through which water can be injected into the sulfuric acid stream. Furthermore, a static mixer, which is not shown in the figure, can also be included in the mixing chamber 3 .

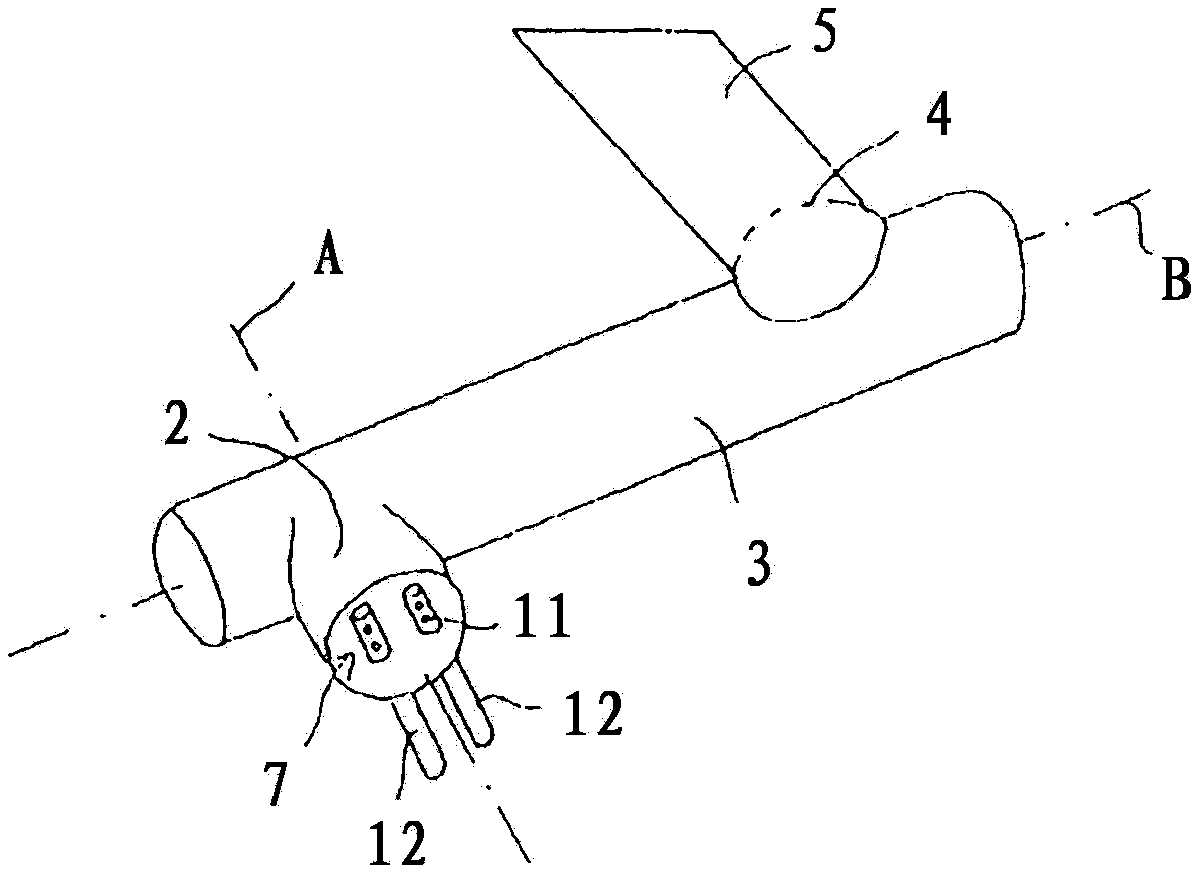

[0025] figure 2 shows a facility for concentration regulation according to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com