A kind of copper-nickel-tin alloy and its preparation method and application

A copper-nickel-tin and copper alloy technology, which is applied in the fields of intelligent forming, energy mining, aerospace, and copper-nickel-tin alloys, can solve the problems of large concentration, difficult control of alloy structure uniformity, difficult material forming and processing, etc. The effect of improved abrasive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

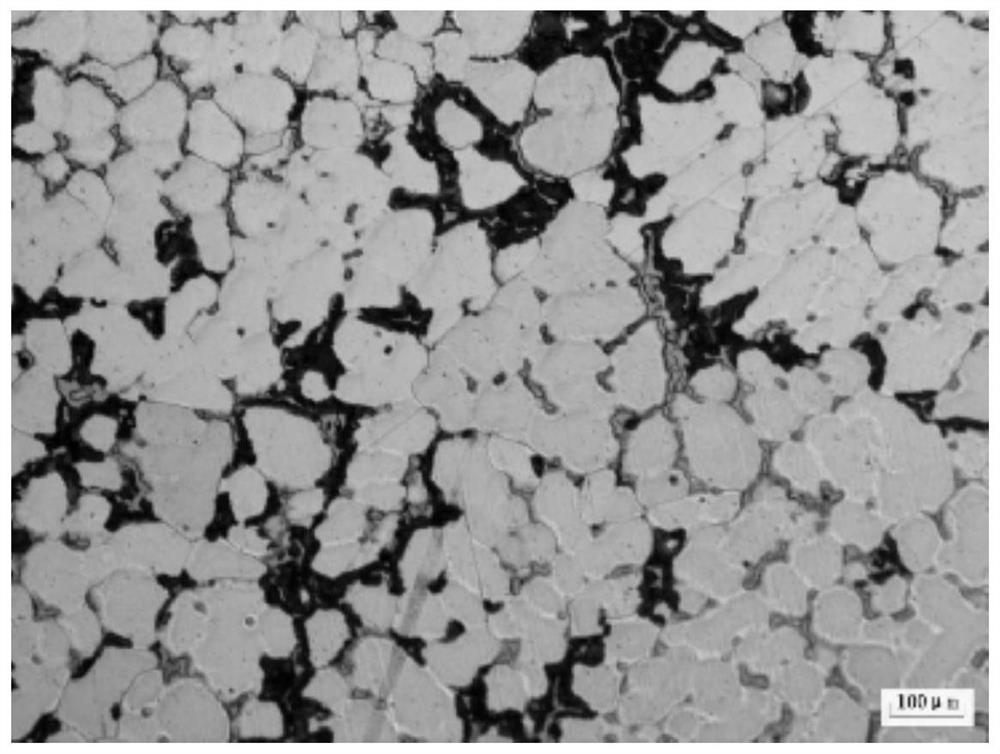

Image

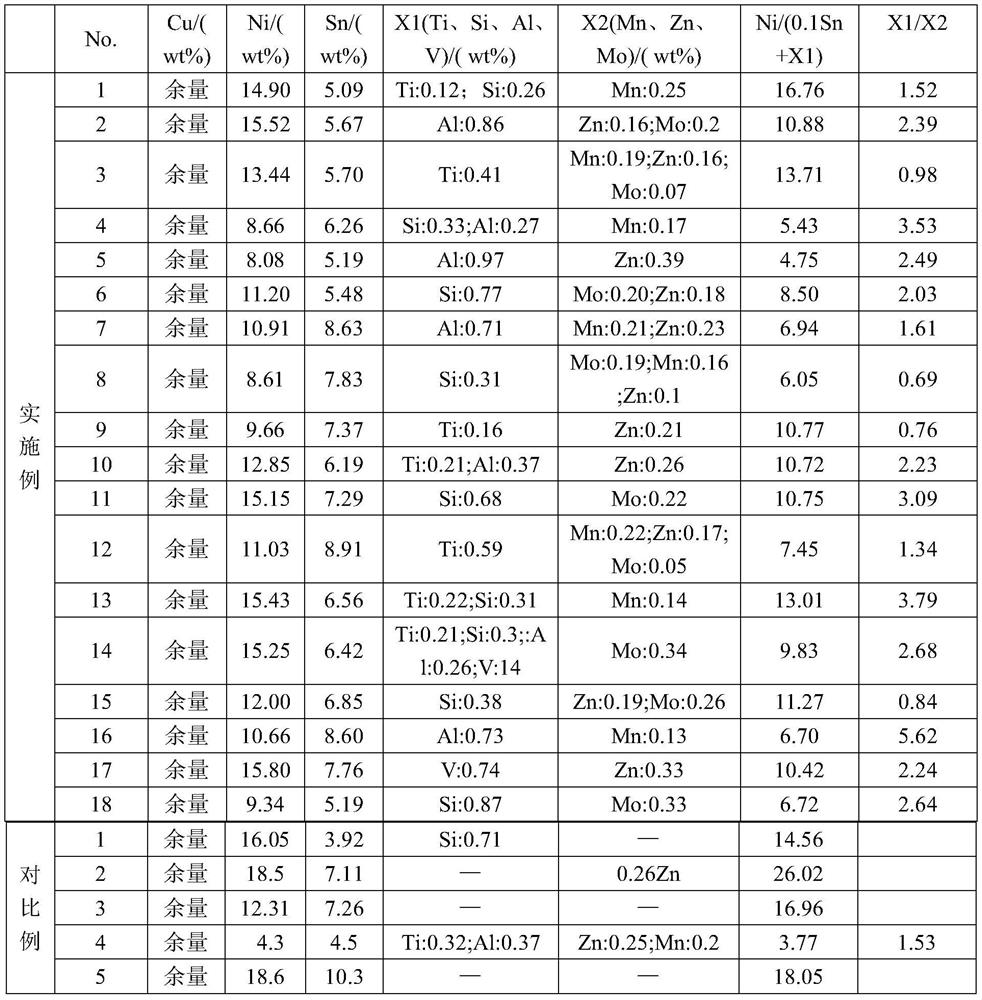

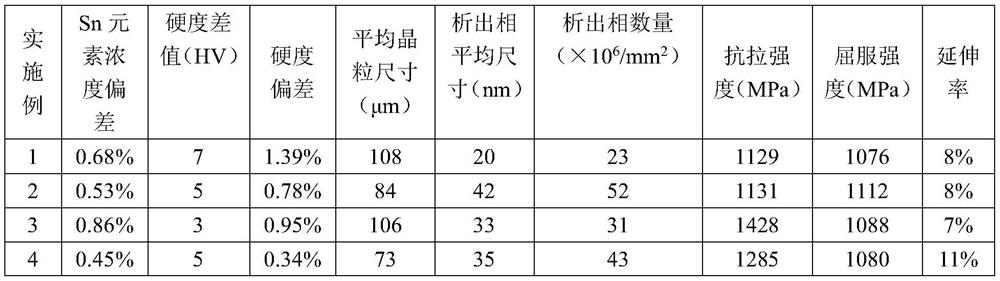

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below with reference to specific embodiments.

[0048] The method of the present invention is used to prepare a CuNiSn alloy ingot with a diameter of 200 mm, and the preparation process is as follows:

[0049] The first choice is to smelt in an intermediate frequency induction furnace according to the designed alloy composition, and the smelting temperature is 1000-1200 °C; then electromagnetic stirring process + semi-continuous casting process is used, the casting temperature is 1100-1300 °C, and the casting speed is 2500-3500mm / h, the stirring current is 100~500A, and the stirring frequency is 5~20Hz, to obtain an ingot with a diameter of 200mm, and measure the Sn concentration deviation from the core to the surface layer of the ingot head; then keep the temperature at 800~900℃ for 6~12h Homogenization annealing is carried out to diffuse the alloy elements and promote the homogenization and fine distribution o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com