Machining device of thin and long in-hole groove

A processing device and technology for slender holes, applied in the field of processing devices for grooves in slender holes and processing devices for grooves in holes, can solve the problem of low processing efficiency, low precision, and low economic cost of slender inner hole grooves and other problems to achieve the effect of saving manual adjustment time, high processing precision and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

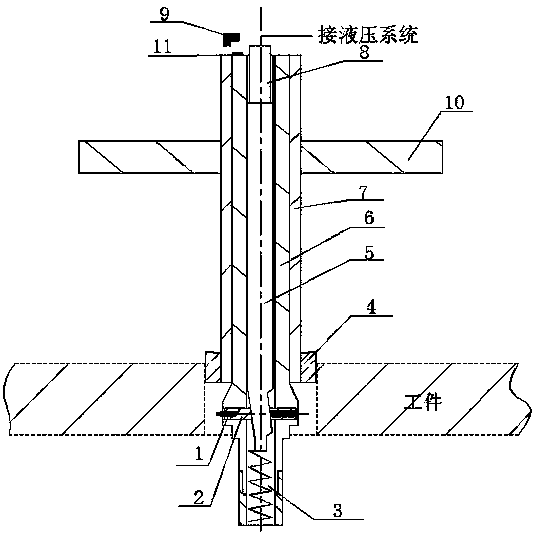

[0014] Such as figure 1 shown.

[0015] A processing device for grooves in elongated holes, which includes a fixed frame 10, a positioning block 4, an outer sleeve 7, an inner sleeve 6 and a push rod 5, and the positioning block 4 is used for inserting on a workpiece to be processed. In the elongated hole of the groove, the shape of the positioning block 4 is preferably a truncated cone structure to realize its self-centering in the elongated hole of the workpiece. In addition, the positioning block 4 can also be designed as a card with an adjustable outer diameter. Disk structure to meet the needs and centering of inner holes of different diameters. One end of the outer sleeve 7 is fixedly connected with the fixing frame 10, and the other end is fixedly connected with the positioning block 4. The inner sleeve 6 is rotatably set in the outer sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com