Process for preparing C-shaped support for vacuum glass

A technology of vacuum glass and manufacturing process, which is applied in the field of vacuum glass manufacturing, which can solve problems such as poor consistency, difficulty in fixing, and poor flatness of finished products, and achieve the effects of reducing use costs, improving flatness, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

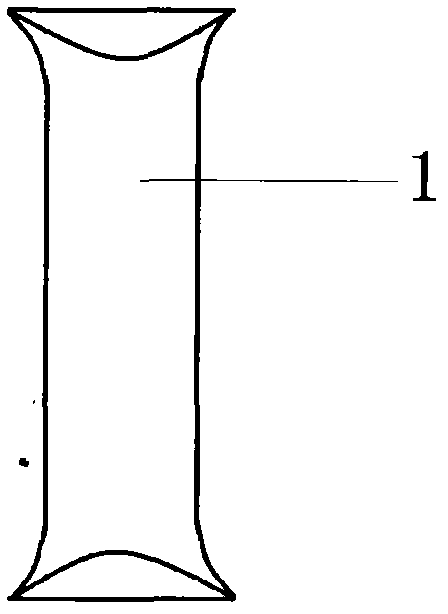

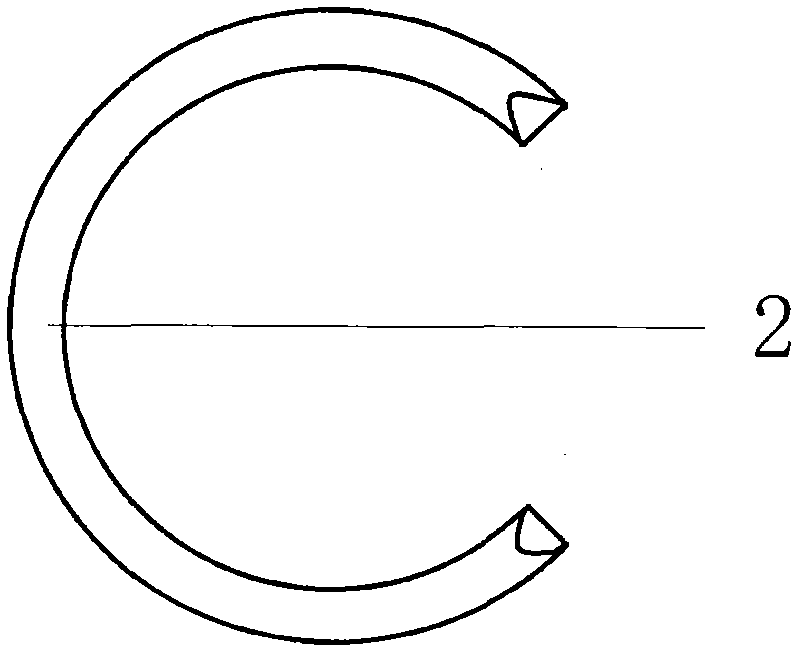

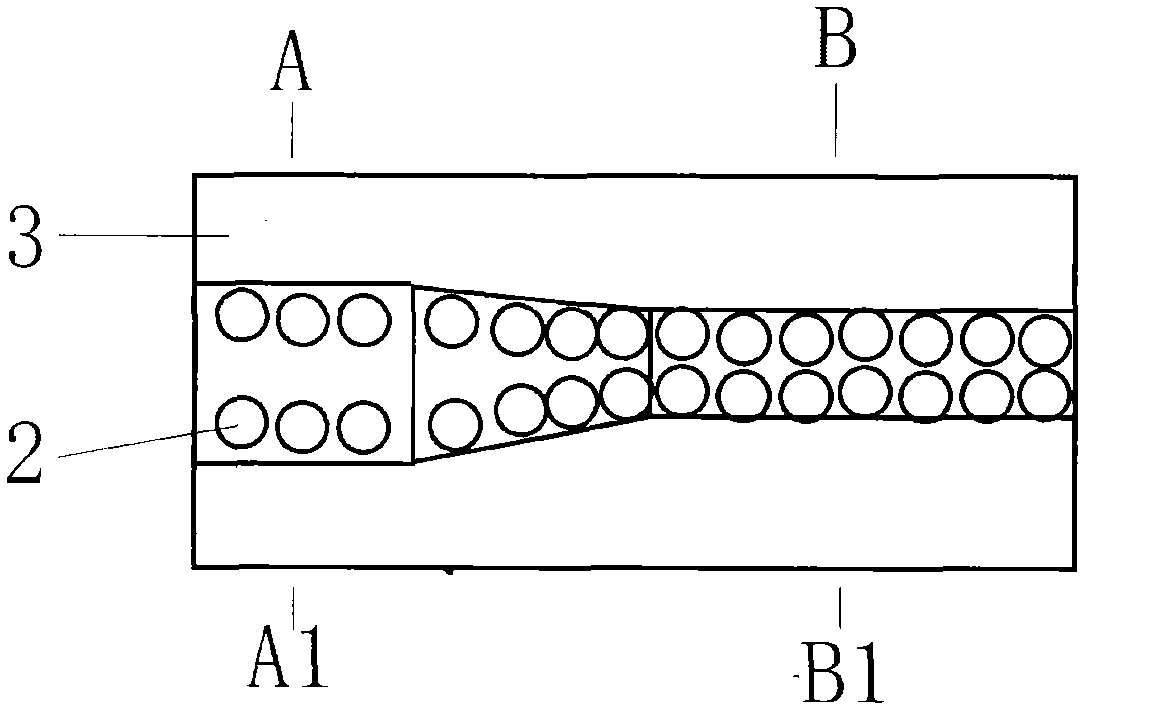

[0021] Such as figure 1 The wire shown is cut into segments and placed into Figure 8 In the shown bending groove, the metal wire is bent into a U shape by being pressed down by the pressure rod 8, and then the U-shaped wire is fed into such as image 3 In the closing guide groove with the closing section shown, under the action of external force, the U-shaped metal wire moves from left to right, and at the closing section of the closing guide groove, the opening of the U-shaped metal wire becomes smaller under the extrusion of the two walls , into a C-shaped support.

[0022] For clarity, image 3 , Figure 6 , Figure 7 The baffle above the end channel shown is not shown, while the image 3 Middle A---A1 section Figure 4 And B---B1 section Figure 5 In, all have baffle plate 4. Such as Figure 9 There is a guide pin 5 under the shown baffle plate. Due to the existence of the guide pin 5, the middle of the U-shaped metal wire will not be pressed together. After formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com