Method for disassembling, lifting and transferring closed type station shield to transferring line to be hoisted out

A closed, station-based technology, applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of affecting the construction of surrounding buildings, increasing traffic pressure, and long construction period, so as to shorten the construction period, construction safety, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

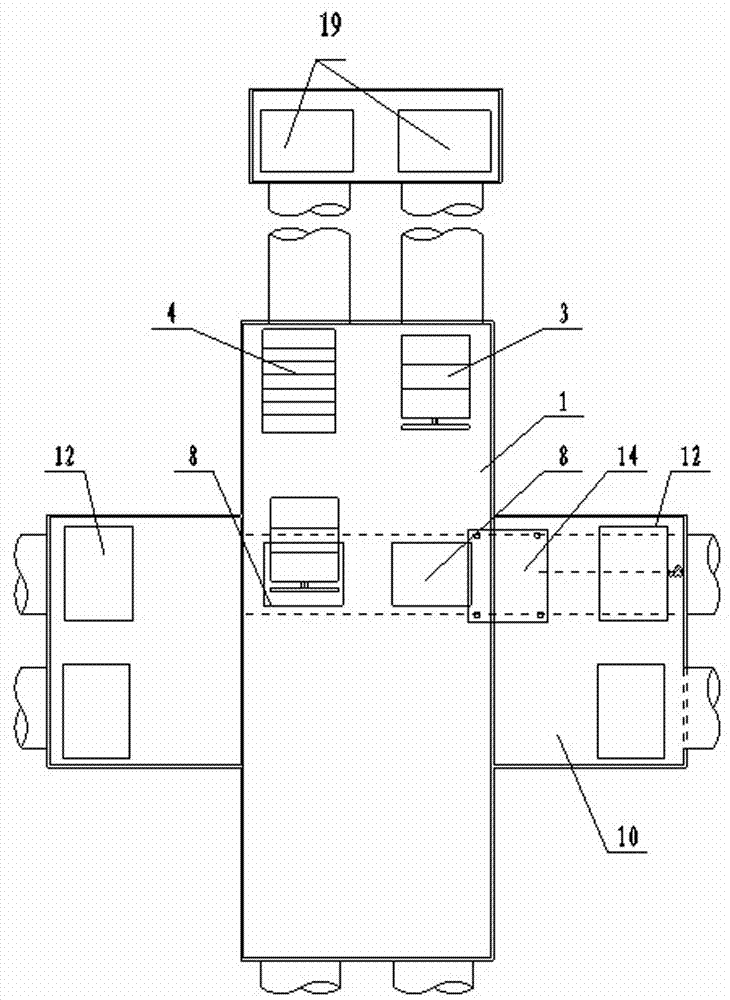

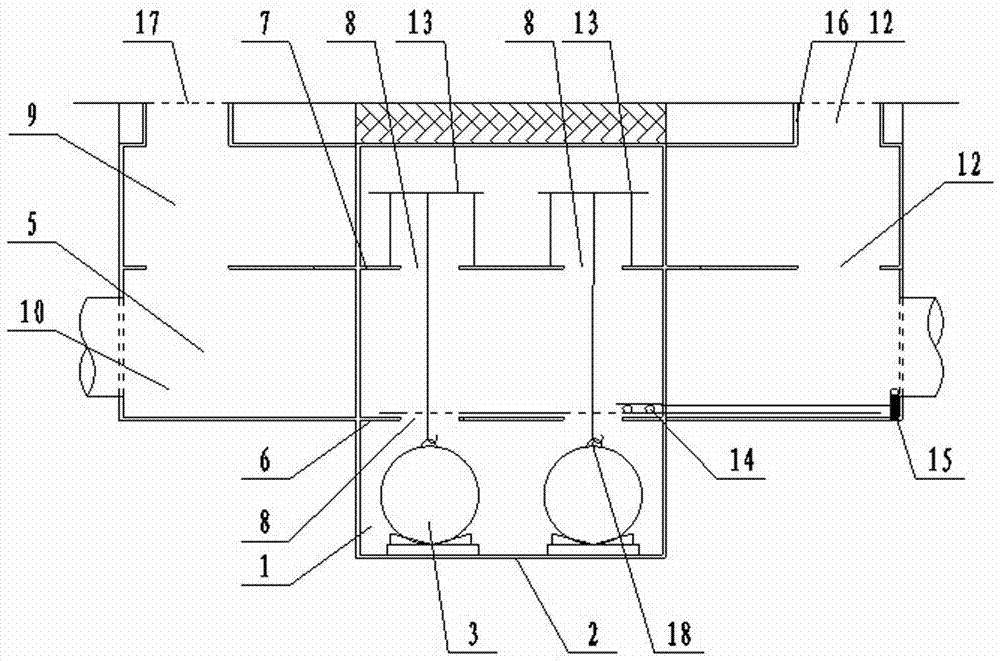

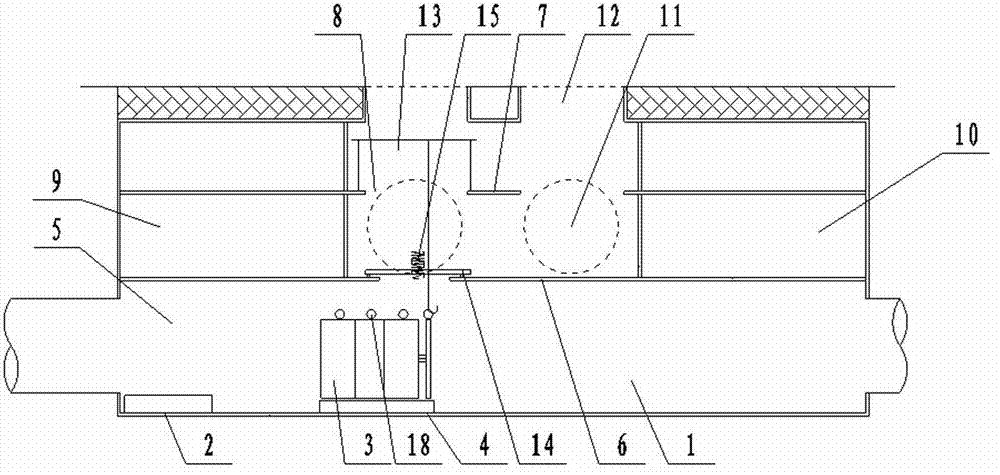

[0027] A method for dismantling and lifting the closed station shield to transfer to the transfer line for hoisting, such as figure 1 , 2 , 3, including the following steps:

[0028] Step 1. Construction of station 1 of the opening line in advance

[0029] A. After the construction of the bottom plate 2 of the station for the earlier opening of the line, the receiving base 4 for the construction of the shield 3 for the earlier opening of the line is installed in advance; B. The middle plate 6 and top plate 7 of the negative second floor 5 are reserved at the intersection of the transfer station during construction Hoisting port 8; C. After the roof of the negative floor 9 is closed, backfill soil to restore traffic;

[0030] Step 2: Construction of station 10 of the later opening line

[0031] A. After the traffic is cleared, carry out the construction of the remaining main body of the station in the later period; B. Reserve the receiving shaft 12 at the end of the station ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com