Saloon car safety belt test auxiliary device

An auxiliary device and seat belt technology, which is applied in the field of car seat belt test auxiliary devices, can solve problems such as time-consuming installation process, cumbersome installation process, and potential safety hazards, and achieve the effects of reducing risks, saving manpower, and simplifying installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

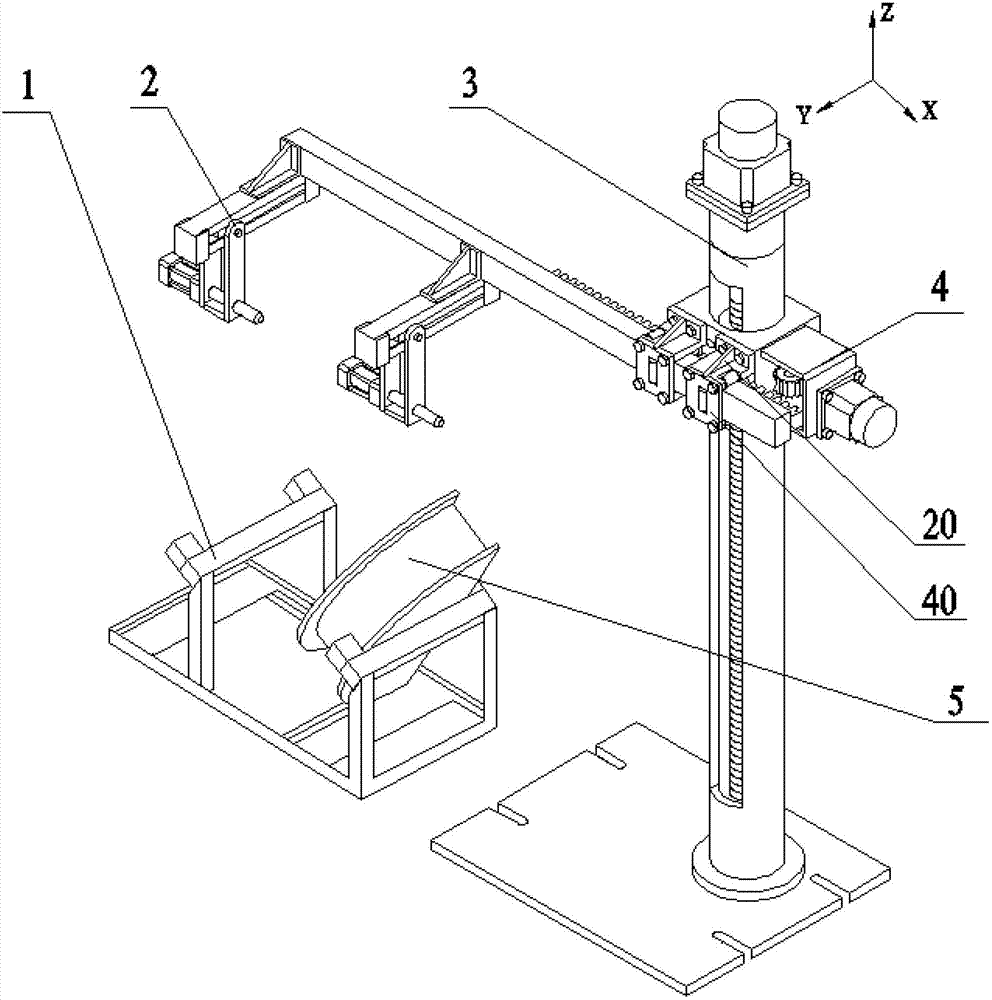

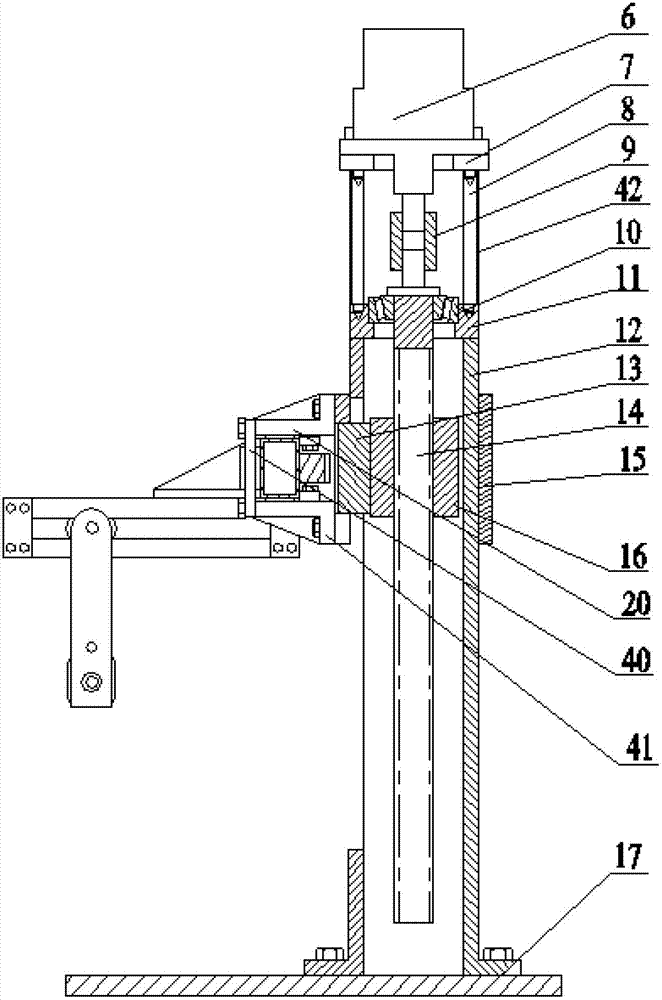

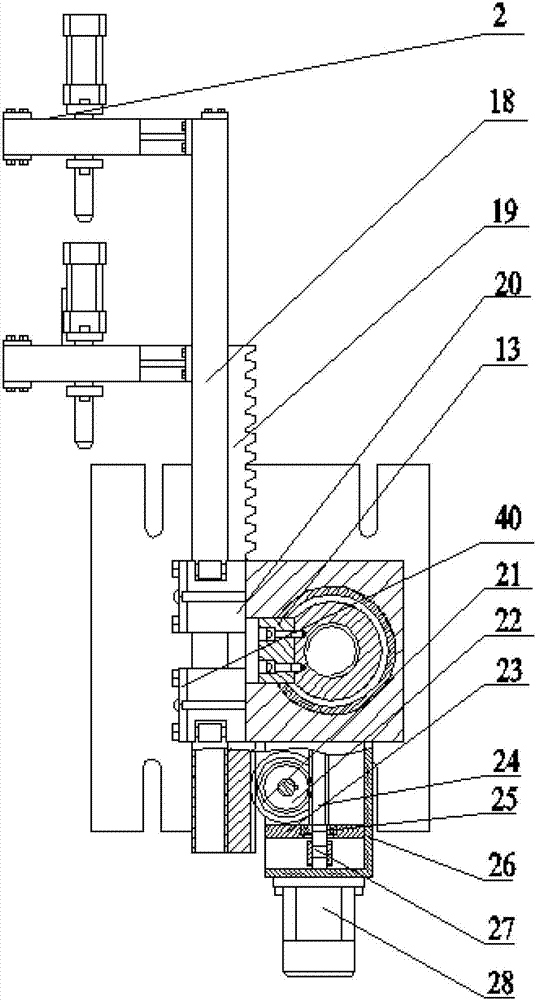

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

[0037] refer to Figure 1 to Figure 3 , the car safety belt test auxiliary device of the present invention is made up of mechanical part and control system, and mechanical part is made up of standard frock 1, 2 clamping mechanisms 2 with the same structure, mechanical transmission mechanism 3 and deceleration mechanism 4. The clamping mechanism 2 completes the clamping and positioning of the safety belt false chest model 5 by the clamping cylinder 34 . The mechanical transmission mechanism 3 and the reduction mechanism 4 are driven by the lifting motor 6 and the motor 28 to complete the transmission of the seat belt false chest model 5.

[0038] Most of the car safety belt test auxiliary device of the present invention adopts a pipe structure, and the overall weight of the mechanism is reduced under the condition of satisfying the structural rigidity, so that it is more conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com