Method for water-impact-resistant test on building element after fire-resistant test

A technology for building components and fire resistance testing, which is applied in the direction of applying repetitive force/pulse force to test the strength of materials, which can solve problems such as lack of inspiration, and achieve the effect of meeting the needs of stable water pressure and ensuring the safety of life and property.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

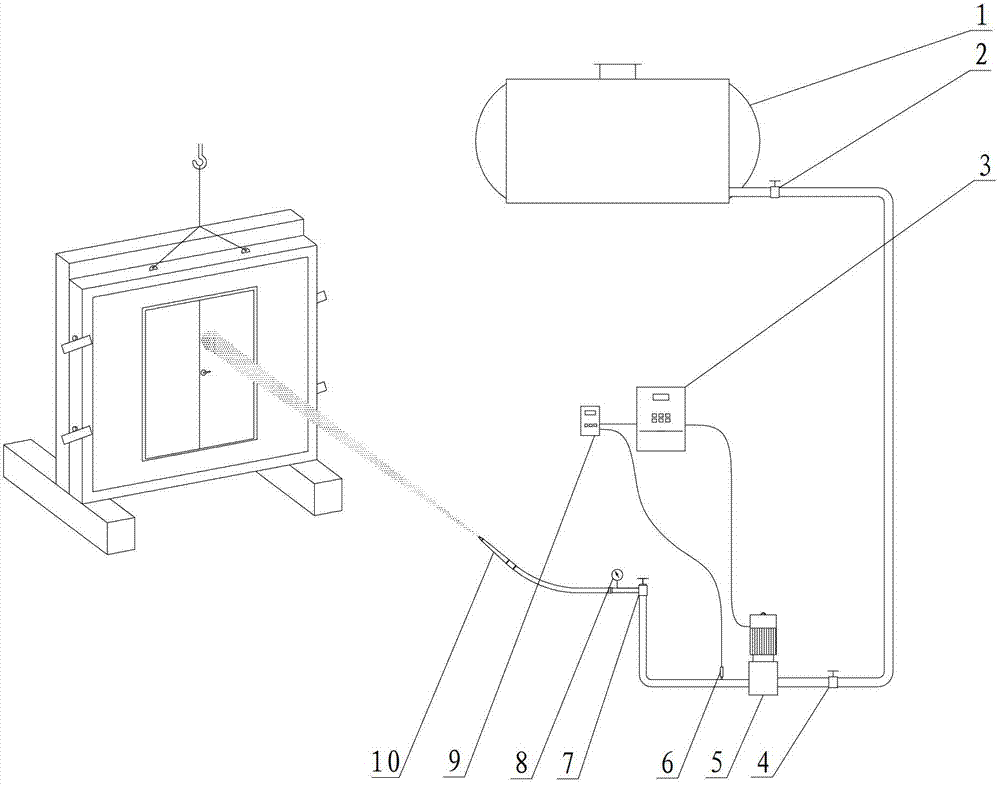

[0033] Such as figure 1As shown, in this embodiment, a device for water impact resistance test after fire resistance test of building components includes: water tank 1, maintenance valve 2, main pipeline valve 4, water pump 5, frequency converter 3, PID controller 9, pressure sensor 6, regulator Pressure valve 7, pressure gauge 8, water gun 10. The water outlet of the water tank 1 is connected to the maintenance valve 2, the maintenance valve 2 is connected to the main pipeline valve 4 through the pipeline, the main pipeline valve 4 is connected to the water pump 5 through the pipeline, the downstream pipeline of the water pump 5 is provided with a pressure sensor 6, and the downstream pipeline of the pressure sensor 6 is set A pressure regulating valve 7, a pressure gauge 8 is set behind the pressure regulating valve 7, and the downstream of the pressure gauge 8 is connected to the water gun 10 through a pipeline; the water pump 5 is connected to the frequency converter 3, th...

Embodiment 2

[0049] Present embodiment except following feature other structures are with embodiment 1:

[0050] In this embodiment, the overall height of the water tank 1 is 10m above the water pump 5, and the volume of the water tank 1 is 10m 3 ; The upper limit of the range of the pressure sensor 6 is 1.0 MPa, and the output signal of the sensor is 4-20 mA.

[0051] After the fire resistance test is over, the building components should be quickly moved to the predetermined flushing position, and the time interval range is 1min.

[0052] In the step (2), the target pressure value is 1.0MPa.

[0053] In the step (3), the distance between the nozzle of the water gun 10 and the surface of the building component is 10m.

[0054] In the described step (3), the speed at which the water column moves on the surface of the building component is 1.0m / s, and the total time for the impact of the water column on the building component is calculated according to the size of the building component, a...

Embodiment 3

[0056] Present embodiment except following feature other structures are with embodiment 1:

[0057] In this embodiment, the overall height of the water tank 1 is 10m above the water pump 5, and the volume of the water tank 1 is 10m 3 ;

[0058] In this embodiment, the upper limit of the measuring range of the pressure sensor 6 is 1.0 MPa, and the output signal of the sensor is 4-20 mA.

[0059] After the fire resistance test is over, the building components should be quickly moved to the predetermined flushing position, and the time interval range is 5 minutes.

[0060] In the step (2), the target water pressure value is 1.0MPa.

[0061] In the step (3), the distance between the nozzle of the water gun 10 and the surface of the building component is 10m.

[0062] In the described step (3), the speed at which the water column moves on the surface of the building component is 1.0m / s, and the total time for the impact of the water column on the building component is calculated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com