A quick identification method for PLC program interlock faults in automatic operation of coke oven locomotives

A technology of automatic operation and identification method, applied in the direction of program control, electrical program control, program control in sequence/logic controller, etc., which can solve problems such as production interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

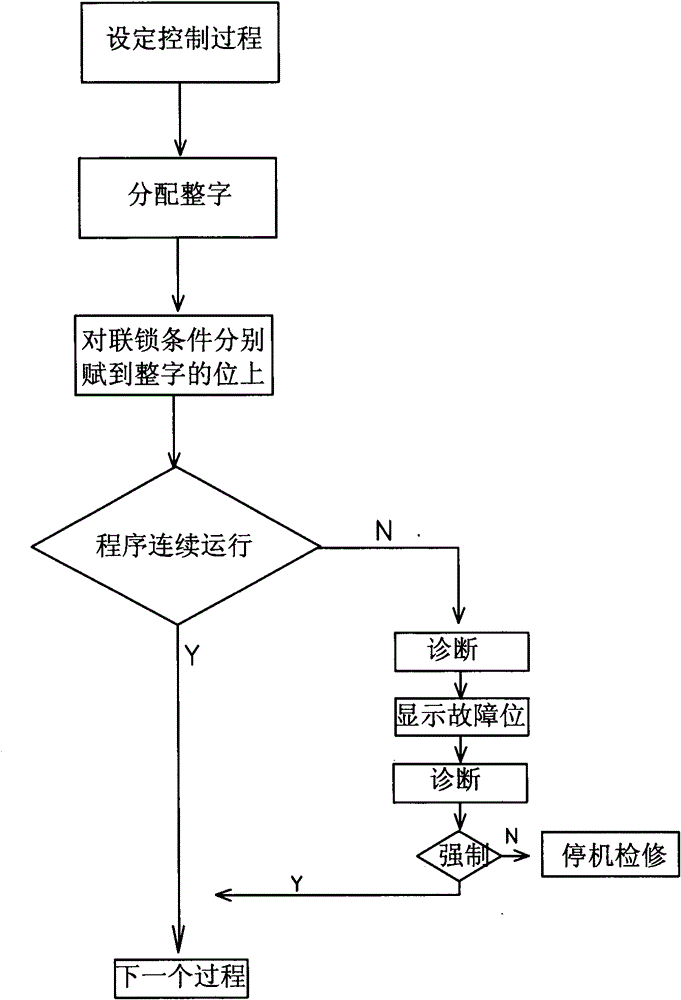

[0016] This embodiment is a quick identification method for PLC interlocking faults in the automatic operation of coke oven locomotives. The process is as follows figure 1 The coke oven locomotive shown is divided into multiple operation steps by its own PLC, and each operation step is divided into multiple operation processes by the PLC for automatic operation. Each operation process has an interlock condition, and the interlock fault is performed according to the following steps Quick identification:

[0017] (1) Set a 16-bit binary integer word or 32-bit binary double integer word for each operating process of each operating step set by the coke oven locomotive PLC, and perform interlocking conditions in each process according to the sequence in the process control List, assign each interlocking condition to each bit of the binary word;

[0018] (2) Set each interlocking condition to be assigned a value of "0" in a non-fault state, and to be assigned a value of "1" when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com