Scraping device with scrapers on scraping blades

A scraper and scraper technology, applied in chemical instruments and methods, cleaning methods using tools, presses, etc., can solve problems that affect the automatic operation of equipment, affect production efficiency, affect scraping effect, etc., to ensure automatic operation. , the effect of improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

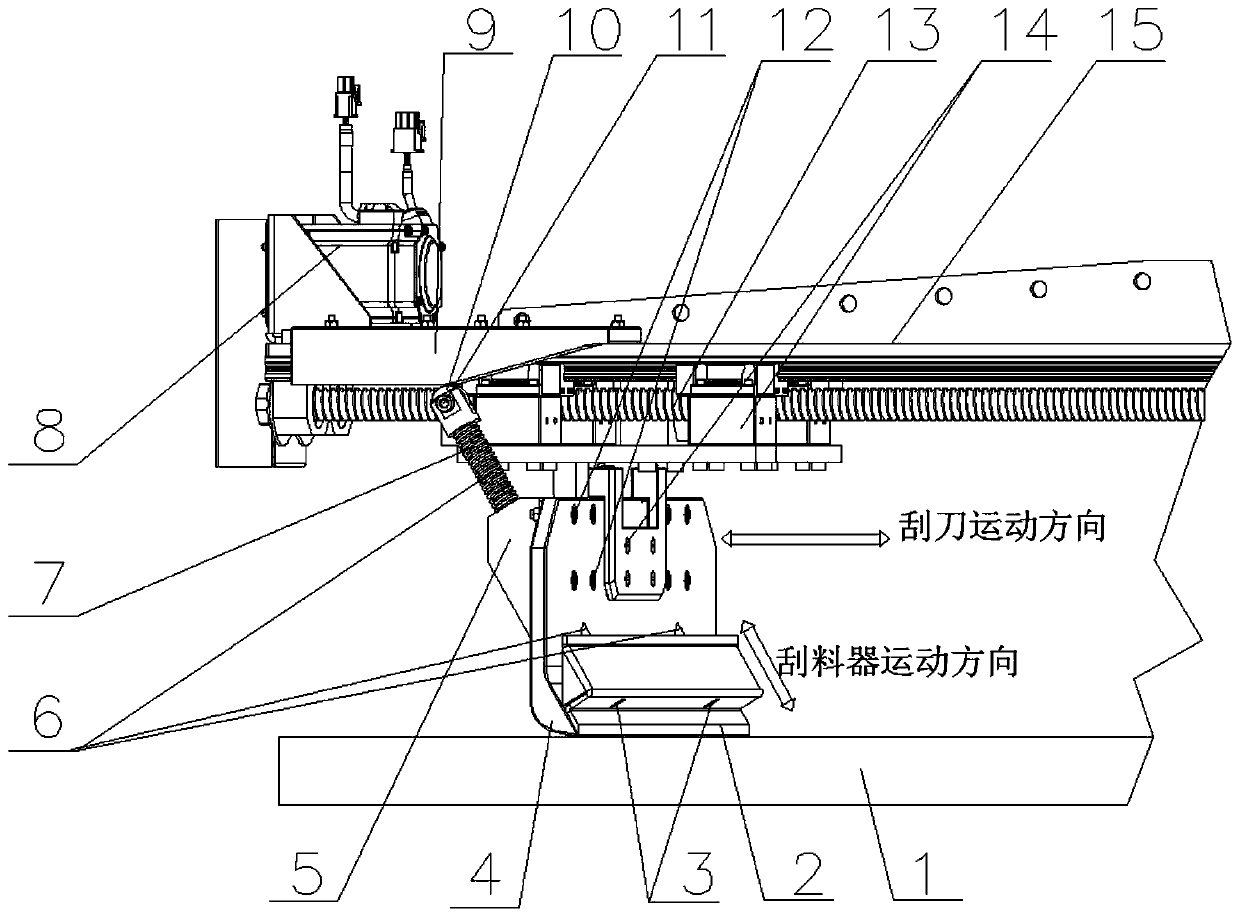

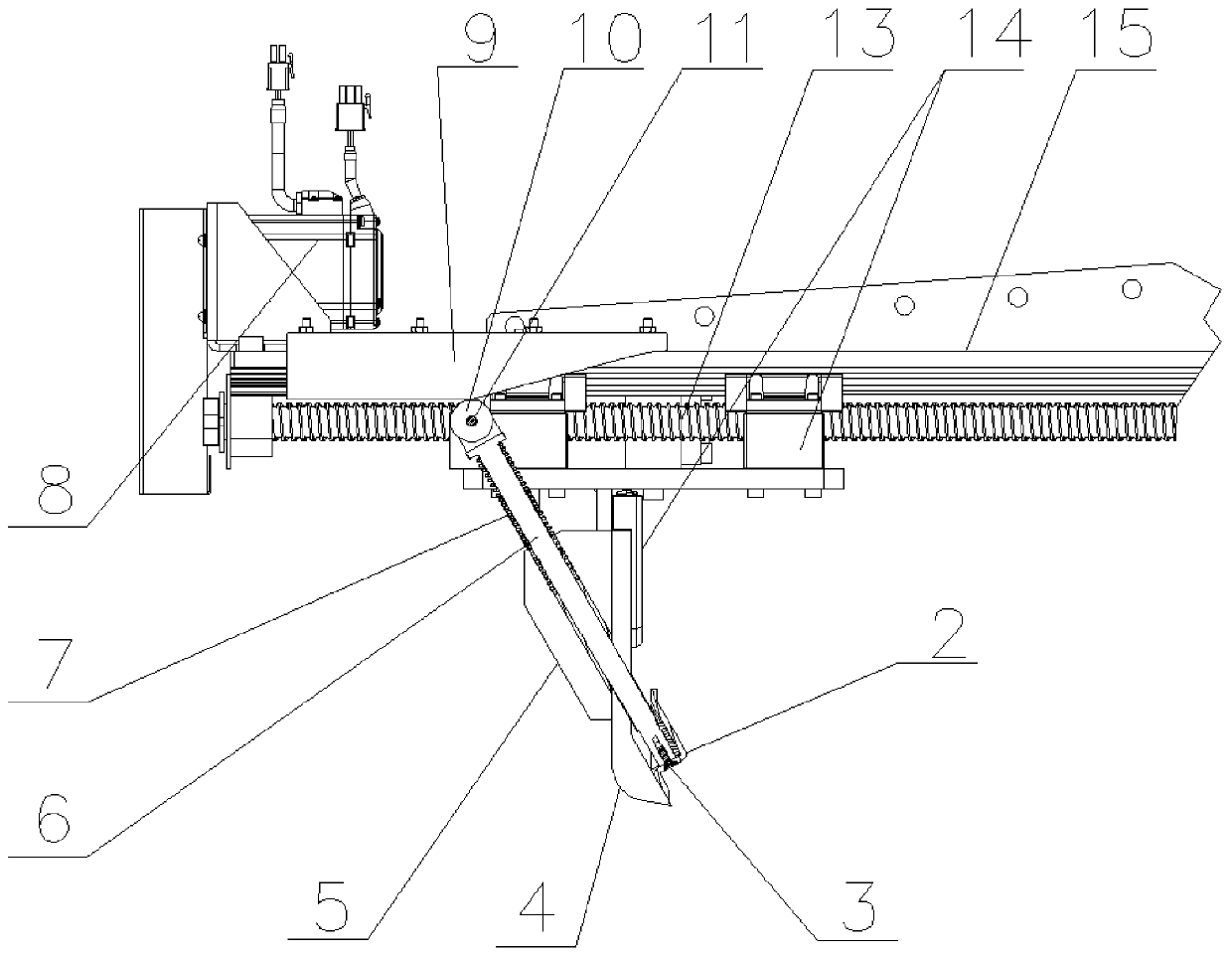

[0016] Such as figure 1 and figure 2 , this embodiment provides a scraper device with a scraper on the scraper, which is located above the worktable 1 and is used to scrape up the composite adhesive material on the worktable 1, including a beam 15, a bevel 9, a drive assembly, Scraper seat 14, scraper 4, scraper 2, slide bar 6, sliding sleeve 5, spring 7. The bevel 9 and the driving assembly are respectively arranged on the beam 15, the top of the scraper seat 14 is connected to the driving assembly, the bottom of the scraper seat 14 is connected to the scraper 4, and the scraper 2 is in contact with the slope at the bottom of the scraper 4. Then, the scraper 2 is connected to the bottom of the slide bar 6 through the screw 3, the top of the slide bar 6 runs through the scraper 4 in turn, the sliding sleeve 5 abuts against the bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com