Smoke purifying device and smoke exhauster

A technology of oil fume purification and oil fume tubes, which is applied in the direction of combined devices, oil fume removal, chemical instruments and methods, etc., can solve the problems of high operating costs, troublesome management, complicated equipment, etc., and achieve low cost, low manufacturing cost, and simple product structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

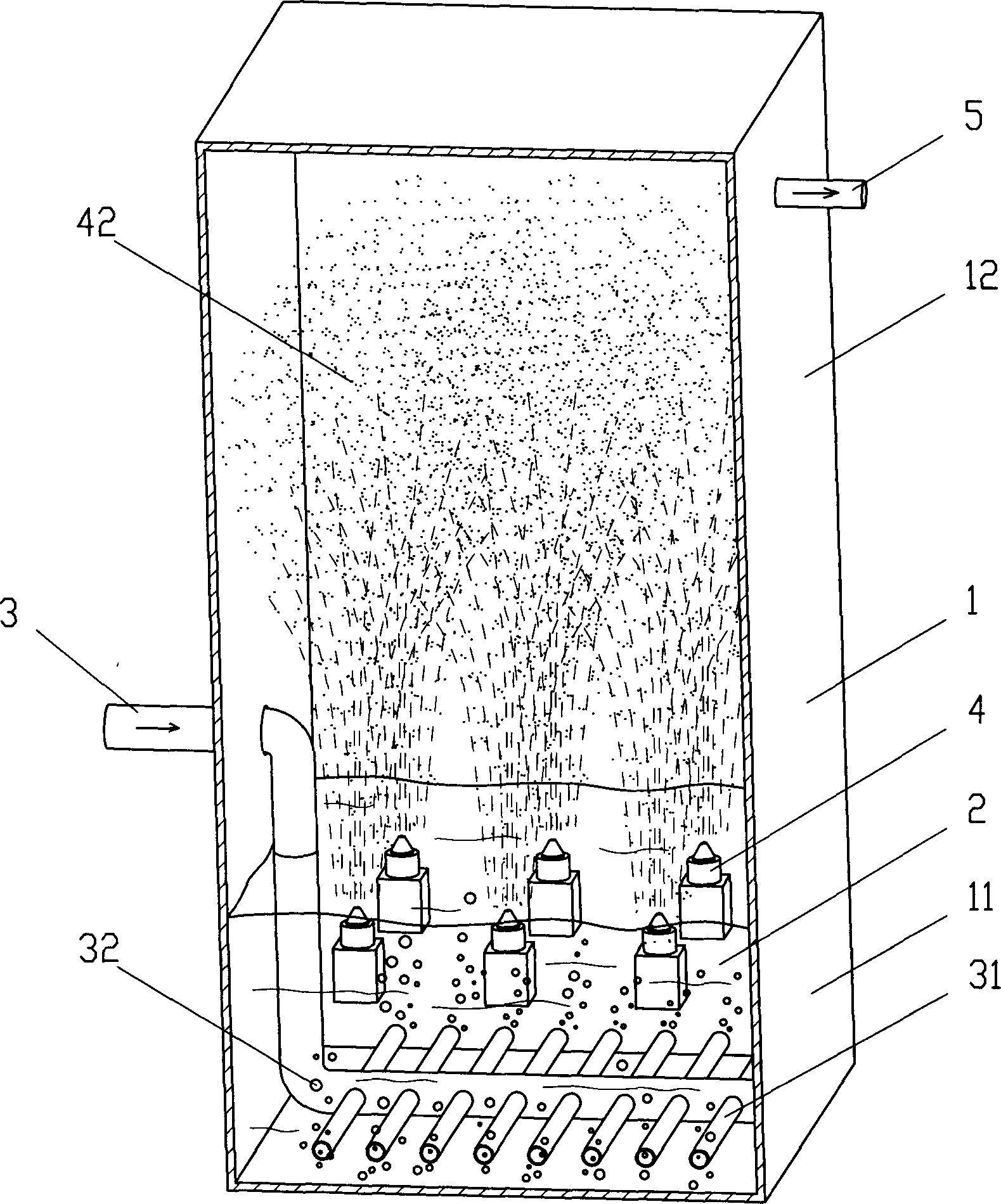

[0037] Example 1: Oil fume purification device of the present invention

[0038] reference figure 1 In this embodiment, the processing box (1) is made of a transparent, easy-to-clean, non-oily material, which facilitates observation and cleaning of sewage.

[0039] The treatment tank (1) is filled with a treatment liquid (2), which is water or a lipophilic aqueous solution, such as detergent with surfactant ingredients. The end of the oil fume pipe (3) is immersed in the treatment liquid (2), and is connected with a gas dispersion device (31). The gas dispersion device (31) has a small pipe with a through hole or a foamed stone made of porous material. The gas dispersion device (31) is immersed in the treatment liquid (2) to disperse the oil fume sent in the oil fume pipe (3) into many tiny bubbles (32) and discharged; a large number of bubbles are formed in the treatment liquid (2), increasing the oil fume The contact area with the treatment liquid is conducive to efficient water...

Example Embodiment

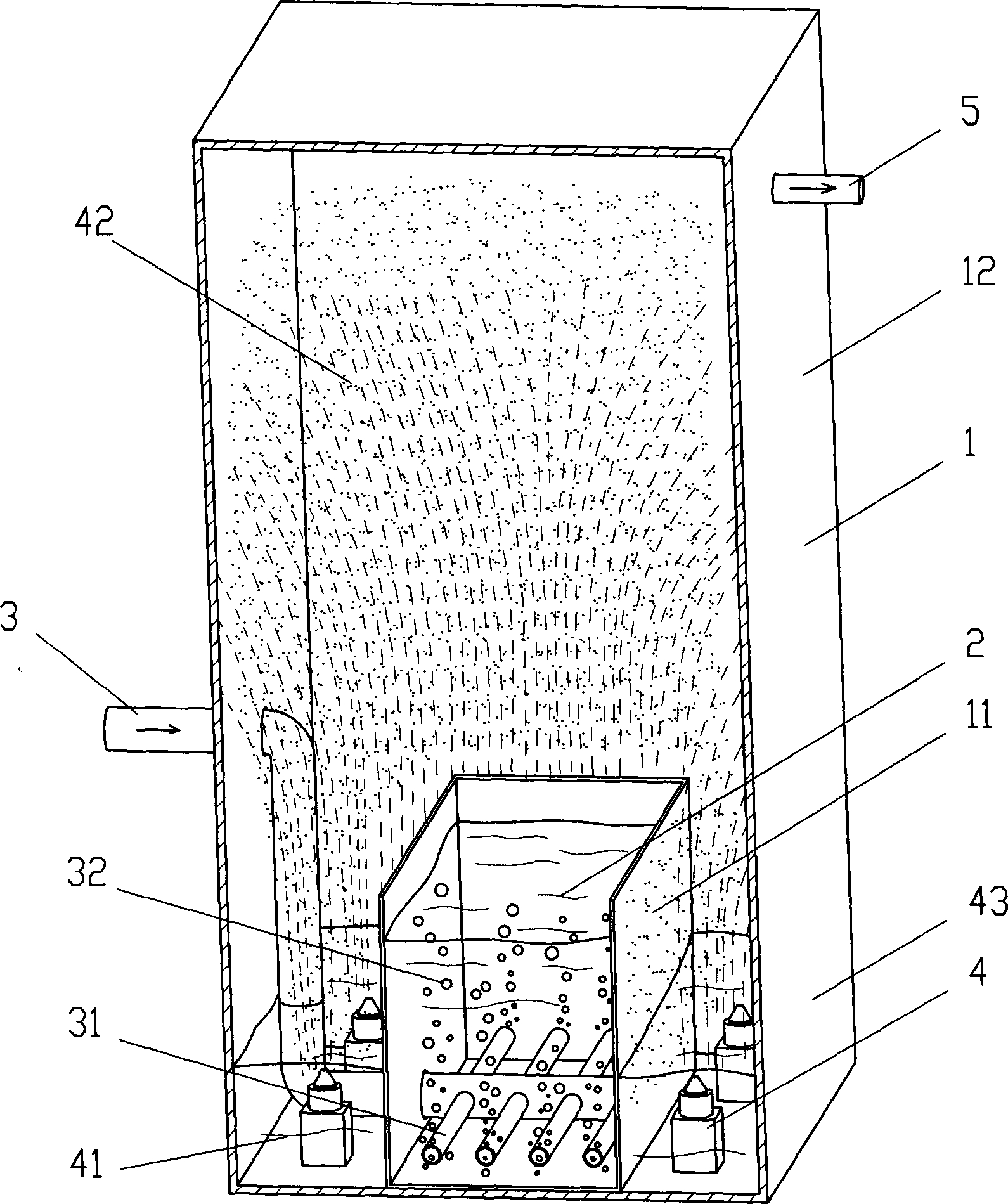

[0046] Example 2: Oil fume purification device with the atomizer of the present invention installed around the treatment liquid container

[0047] reference figure 2 This embodiment is basically the same as embodiment 1, but the difference lies in that: in the atomizer box (43) of this embodiment, a treatment liquid container (11) is provided near the center. The treatment liquid container (11) is filled with a treatment liquid (2), and the atomizer box (43) is filled with an atomization liquid (41). The treatment liquid (2) uses tap water, and the atomization liquid (41) uses tap water added with detergent.

[0048] The atomizer box (43) contains the atomization liquid (41), the treatment liquid container (11) contains the treatment liquid (2), the atomization liquid (41) is immersed in the ultrasonic atomizer (4), and the treatment liquid The gas dispersion device (31) is immersed under the container (11).

[0049] This design can configure the treatment liquid (2) and the atomi...

Example Embodiment

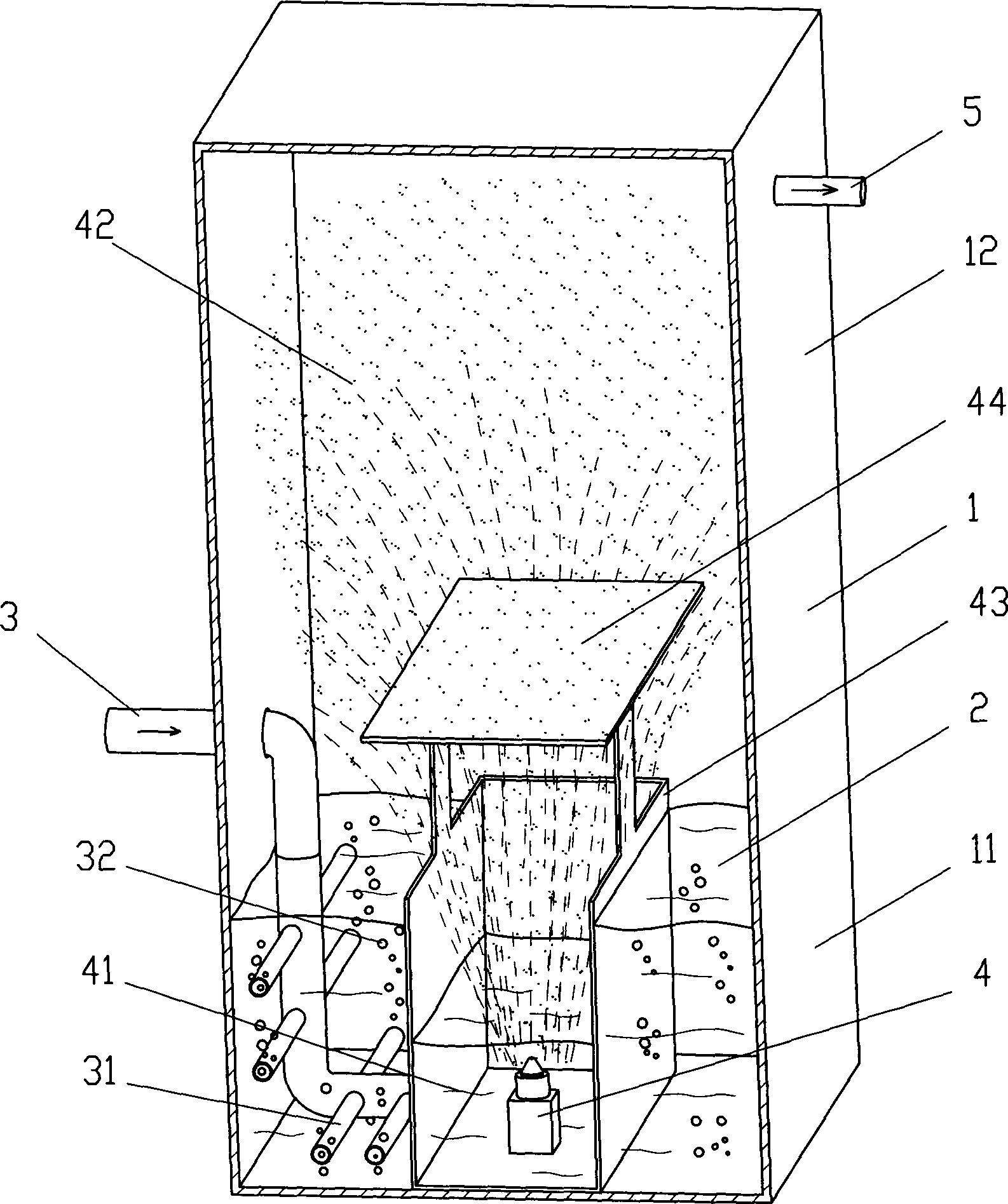

[0050] Embodiment 3: The structure diagram of the oil fume purification device with the atomizer of the present invention installed in the center of the treatment liquid container

[0051] reference image 3 This embodiment is basically the same as Embodiment 2, but the difference lies in that: in the processing liquid container (11) of this embodiment, near the central area, an atomizer box (43) is provided. The atomizer box (43) contains an atomization liquid (41) and an ultrasonic atomizer (4), and the acoustic atomizer (4) is immersed in the atomization liquid (41).

[0052] The treatment liquid container (11) contains the treatment liquid (2) and the gas dispersion device (31). The gas dispersion device (31) is immersed in the treatment liquid (2); the gas dispersion device (31) disperses the oil fume sent from the oil fume pipe Many tiny bubbles emerge from the treatment liquid (2), which play the role of washing oil fume.

[0053] The top cover plate (44) of the atomization b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com