Composite board of solid wood or bark-peeled single baseboard with grooves

A composite board and veneer technology, which is applied in the jointing of wooden veneers, manufacturing tools, and wood layered products, can solve the problems of high cost and high formaldehyde content of multi-layer solid wood composite boards, and achieve the goal of avoiding tile-like deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

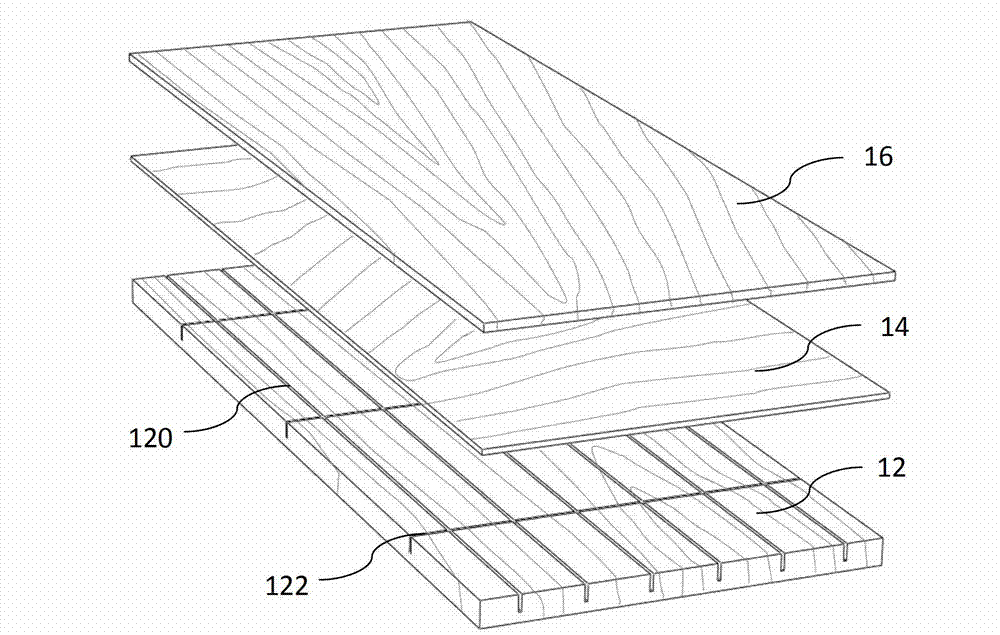

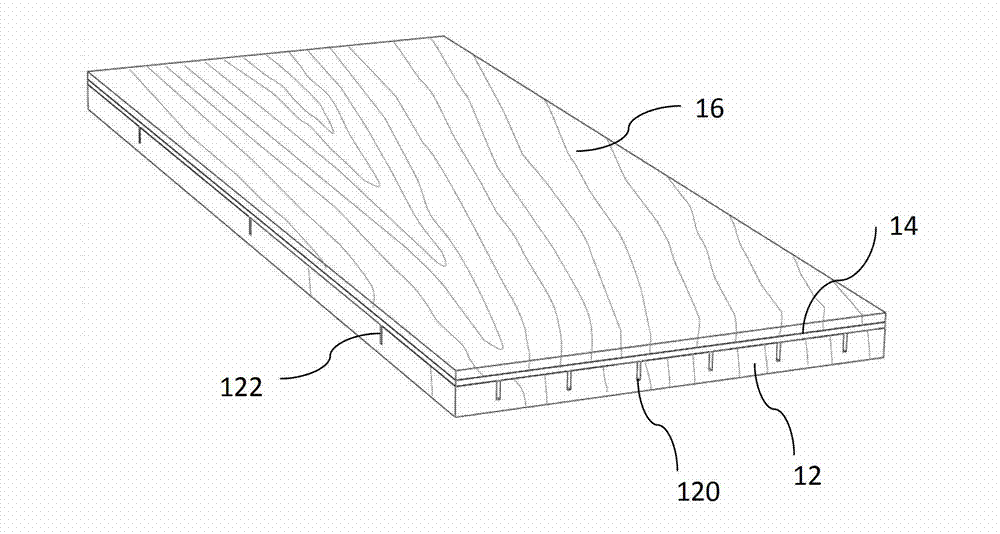

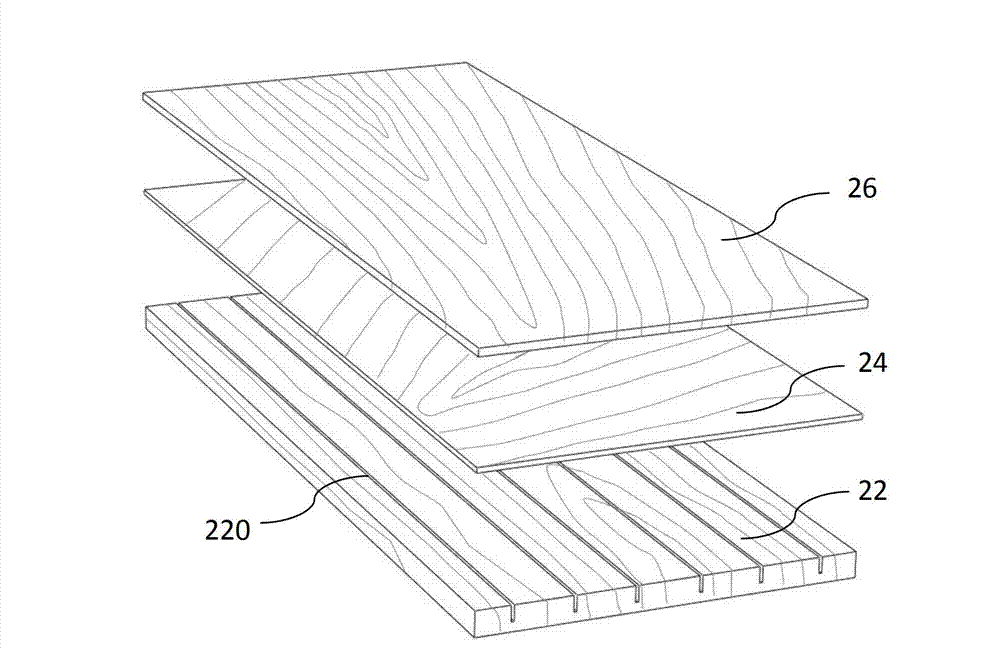

[0037] Cooperate with reference figure 1 As shown, it is an exploded schematic diagram of the first preferred embodiment of the composite plate of the solid wood or the veneer veneer base plate with grooves in the present invention, and the solid wood or veneer veneer base plate 12 of the composite plate can be seen in the figure as Longitudinal wood grain, multiple longitudinal grooves 120 and multiple transverse grooves 122 are equidistantly arranged on the bonding surface of the solid wood or the veneer veneer 12, and the distance between the longitudinal grooves 120 is 10-60mm , the distance between the transverse grooves 122 is 30-600 mm, the width of the longitudinal grooves 120 is 0.5-3 mm, the width of the transverse grooves 122 is 0.5-3 mm, and the depth of the longitudinal grooves 120 is 20%-95% of the thickness of the solid wood or veneer veneer base plate 12, and the depth of the transverse groove 122 is 20%-95% of the thickness of the solid wood or veneer veneer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com