Grooved solid wood middle plate and composite board with same

A grooved, composite panel technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of composite panel deformation, poor cushioning effect of the composite panel surface, etc., to avoid tile-shaped deformation and ensure smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

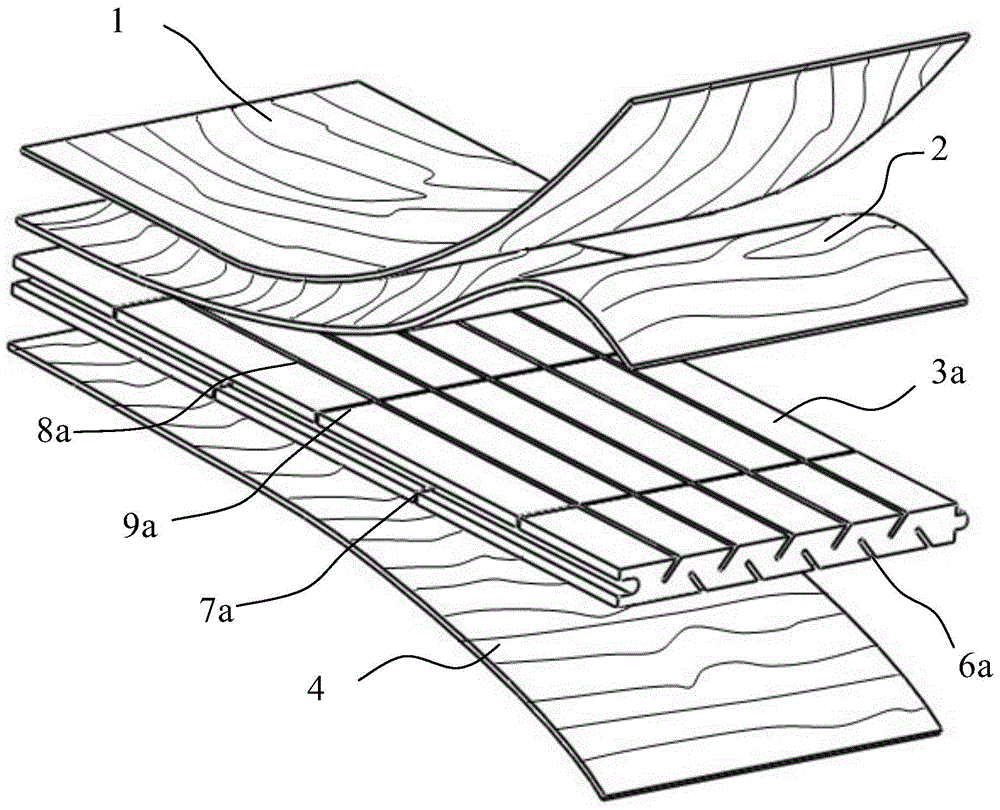

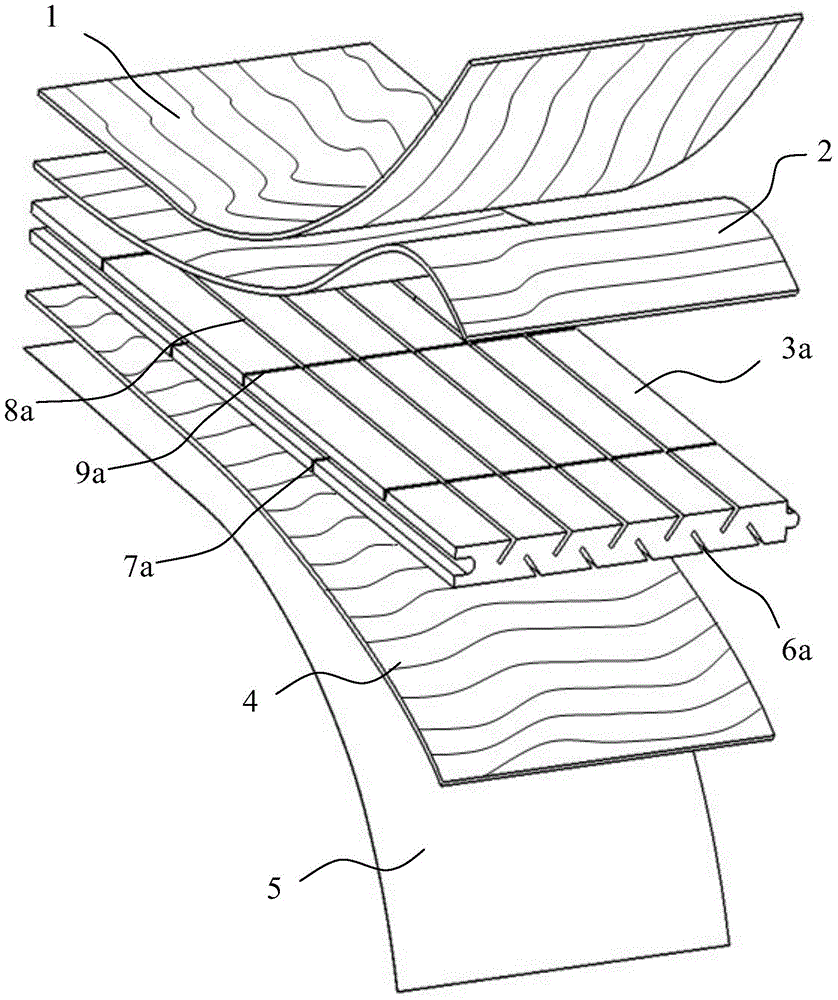

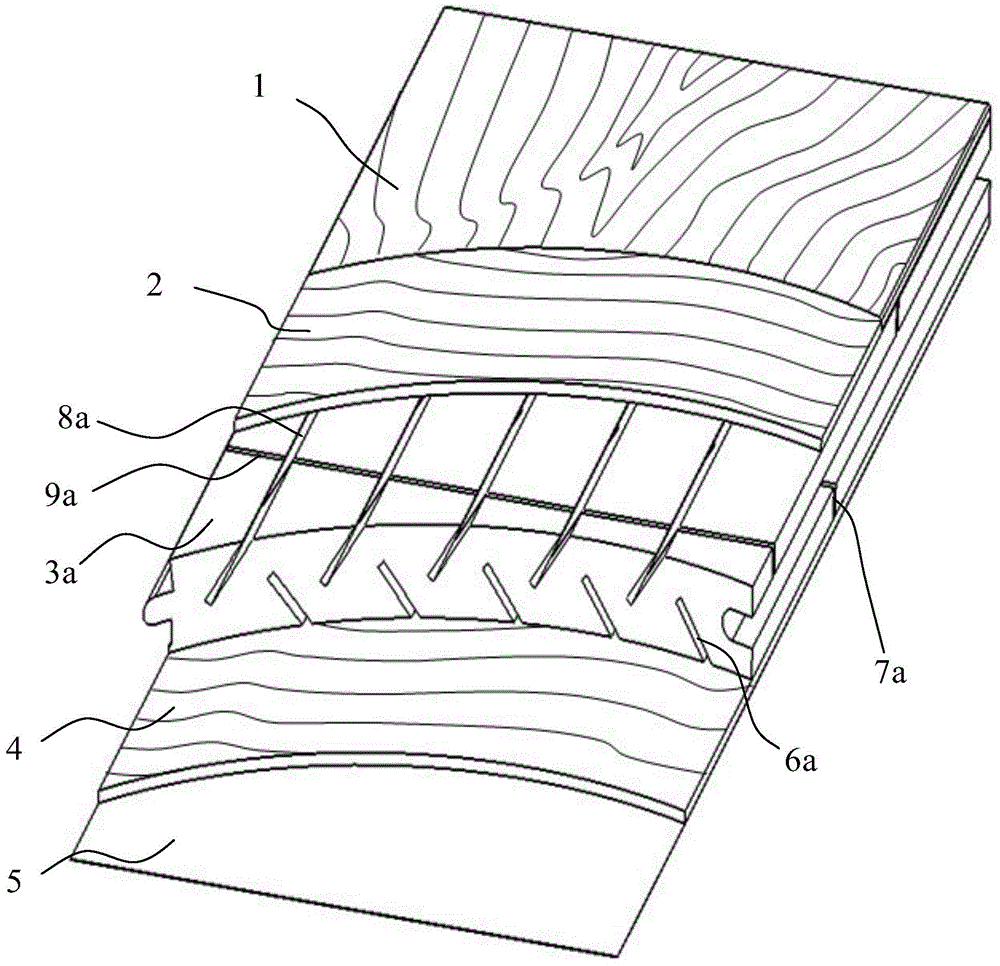

Embodiment 1

[0054] Below the lower veneer 4, a moisture-proof bottom layer 5 made of floor moisture-proof paper, shockproof, moisture-proof and sound-insulating cushion film, elastic material cushion, etc. can be provided, which can effectively isolate the direct contact between the bottom surface of the floor and the ground moisture, and can effectively prevent the floor Moisture deformation, decay and other situations occur, and the floor's moisture-proof, anti-corrosion, sound-absorbing and shock-proof effects are greatly improved. The sawn groove destroys the irregular fiber direction of the floor wood, so as to minimize the internal stress and deformation of the wooden floor. In order to make the floor more flat and obedient without warping, and to improve the moisture inside the floor due to dry climate or high temperature direct sunlight A large amount of loss will cause the separation of the wooden floor and the cracking of the floor surface. Through the vertical and horizontal saw...

Embodiment 2

[0056] The solid wood middle board is made of fir board with a length of 930mm, a width of 135mm, a thickness of 12mm, and a dried moisture content of less than 12%. The longitudinal groove and the second longitudinal groove, the first longitudinal groove and the second longitudinal groove are arranged in opposite directions, and then the first transverse groove and the second transverse groove are sawed respectively on the upper and lower surfaces of the solid wood middle board, The first longitudinal groove and the second longitudinal groove of the solid wood middle plate are arranged at intervals from each other, the groove distance from the (convex) side of the solid wood middle plate to the first groove is 20mm, and the first and second longitudinal grooves The groove spacing is 20mm, and the groove width of the first and second longitudinal grooves is 1mm. The groove depth of the first and second longitudinal grooves is 80% of the thickness of the solid wood middle plate;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com