Thermoforming device and method thereof

A technology of hot press forming and hydraulic tank, which is applied in the field of hot press forming devices, can solve the problems of burrs and overflow, multiple processing instruments, easy damage, etc., and achieve the effect of avoiding secondary processing and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0043] According to the first embodiment, the present invention further proposes a second embodiment for further illustration.

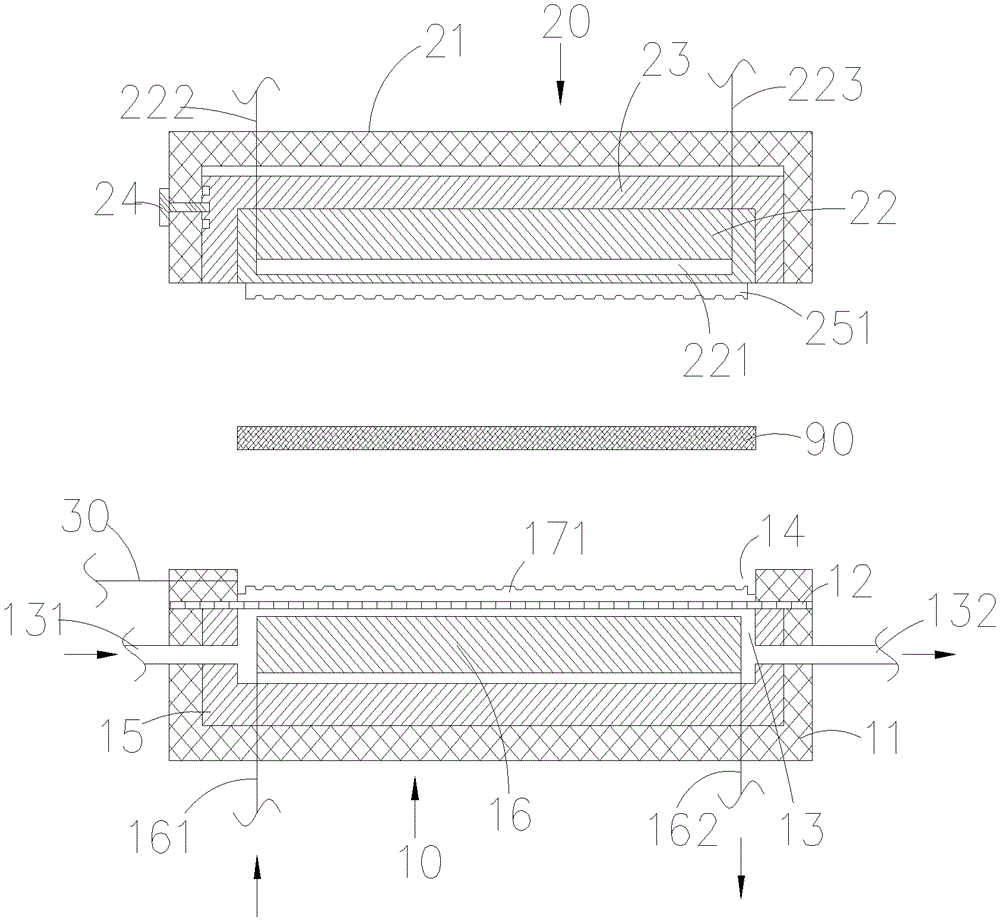

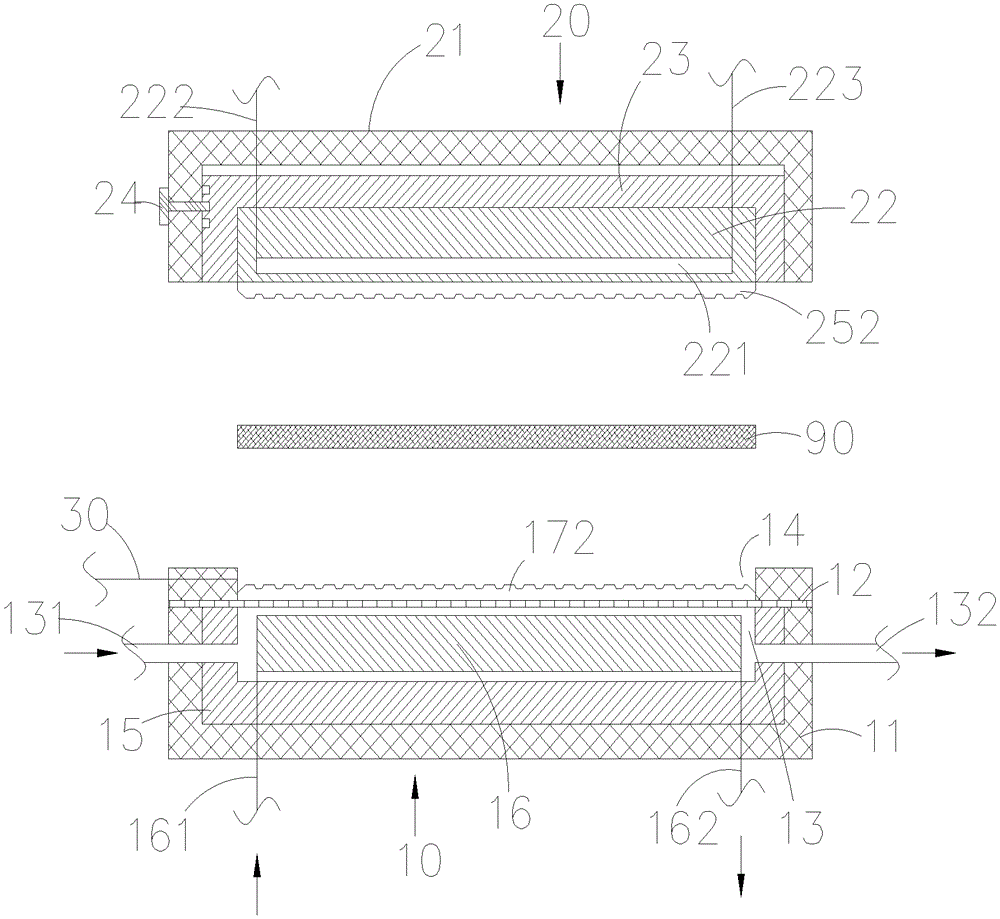

[0044] Please refer to image 3 , which is the first schematic diagram of the second embodiment of the thermoforming device of the present invention. Such as image 3 As shown, the thermocompression molding device of the present invention may include a first mold 10 and a second mold 20, wherein the first mold 10 may include a first template 172 and a first main shell 11, and the second mold 20 may include a second template 252 And the second main shell 21. The elastic heat-conducting film 12 can be arranged on the first mold 10, and the surface edge of the first mold 10 has a first annular structure, and its first annular structure can correspond to a surface of the board to be embossed 90, so that the board to be embossed 90 has a corresponding ring structure figure after molding. Meanwhile, the upper surface of the first template 172 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com