Vibrating feeder with selectable conveying direction

A technology of vibrating feeder and conveying direction, which is applied in the direction of conveyor, vibrating conveyor, transportation and packaging, etc. It can solve the problems of wasting resources, troublesome operation, occupying space, etc., and achieves the advantages of convenient conversion, space saving and resource saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

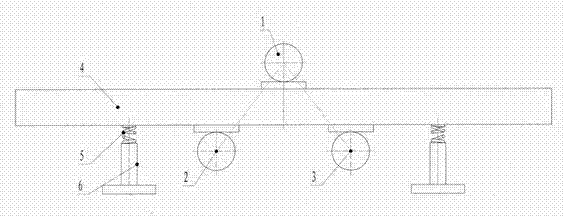

[0008] The embodiment is described in detail with reference to the accompanying drawings. It includes a support 6 on which a horizontal conveying trough 4 is installed with a damping spring 5. The improvement is that a horizontal master is installed upwards in the middle of the top of the conveying trough. The vibration motor 1 is parallel to the axis of the main vibration motor on the bottom surface of the conveying trough, and the rotation direction is opposite, and two vibration-assisting motors 2 and 3 are installed on the left and right in a square shape. When installing, just install a power switch connected to various motors on the console, and install a selector switch on the power cord, which direction the selector switch needs to be conveyed in, so that the side of the vibration aid The main vibration motor works synchronously with the main motor, and the vibration-assisting motor on the other side stops. To meet the design requirements, the operation conversion is ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com