Assembly line type lifting filling machine

An assembly line, filling machine technology, applied in the direction of packaging, bottle filling, liquid bottling, etc., can solve the problems of low degree of automation, waste of medicines, high labor intensity of workers, etc., and achieve simple operation and maintenance, accurate filling measurement, Excellent working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

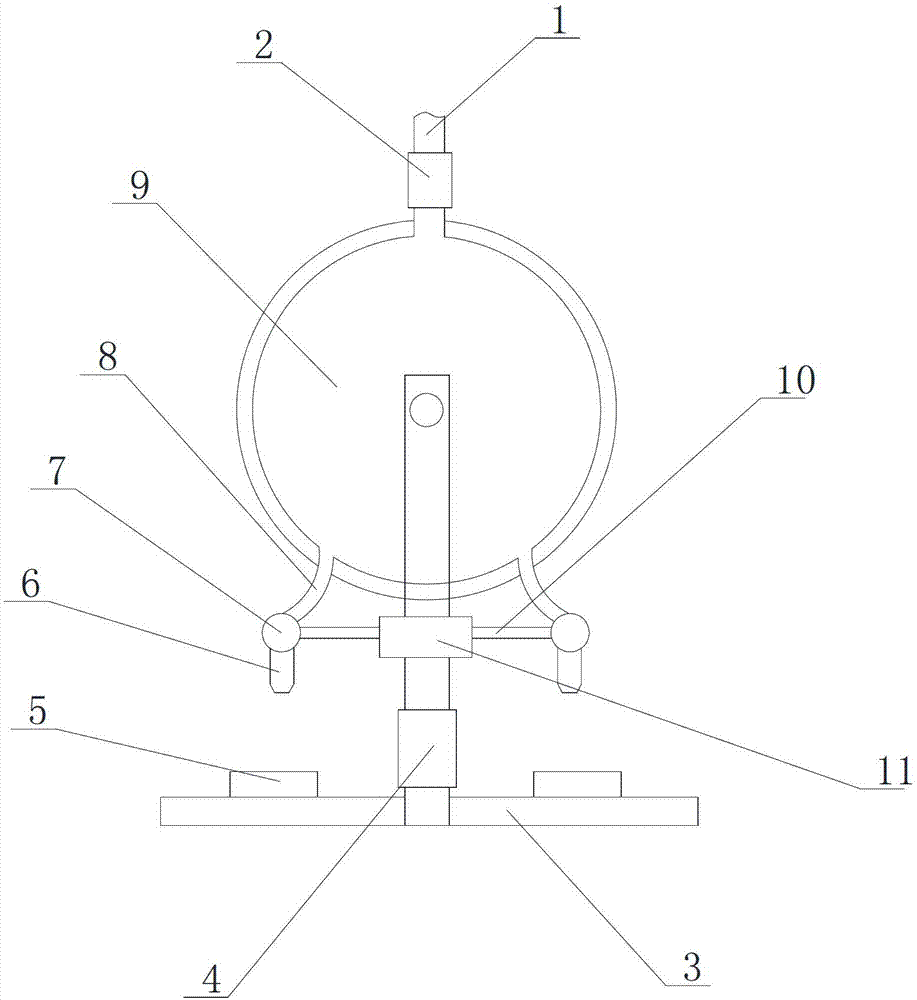

[0020] see figure 1 , a line-type lifting filling machine, including a lifting bracket and a liquid storage tank 9 installed on the lifting bracket, the top of the liquid storage tank 9 is provided with a feed pipe 1, and a control valve 2 is provided on the feed pipe 1. The bottom of the liquid storage tank 9 is provided with a filling mechanism, and the bottom of the filling mechanism is provided with an assembly line conveying mechanism. A control box 11 is installed on the lifting bracket, and a controller is arranged in the control box 11, and the controller is electrically connected to the control valve 2, the filling mechanism and the assembly line conveying mechanism.

[0021] In this embodiment, the filling mechanism includes several filling pipes 6 communicating with the liquid storage tank 9 , the opening direction of the filling pipes 6 is vertically downward, and an assembly line conveying mechanism is directly below the filling pipes. The filling pipe 6 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com