Slasher capable of realizing automatic pattern arrangement and automatic pattern arranging method

A sizing machine and automatic rowing technology, which is applied in the direction of shaft reversing machine, yarn guide device for processing textile materials, liquid/gas/steam yarn/filament processing, etc., can solve the problem of low drawing-in production efficiency and low accuracy of flower arrangement , operating level differences and other issues, to achieve the effect of improving production efficiency and utilization, reasonable structure, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below:

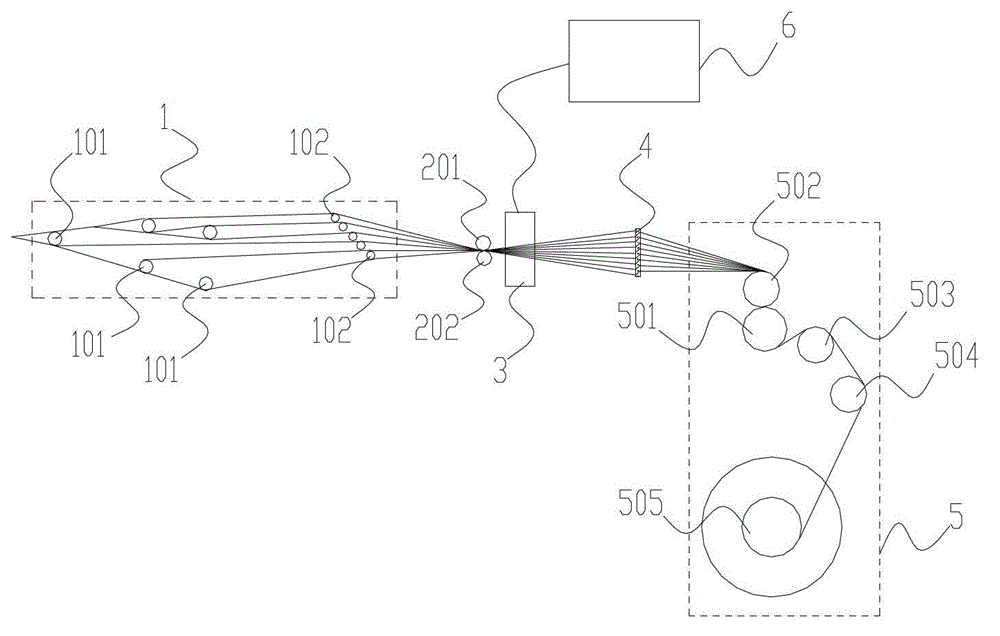

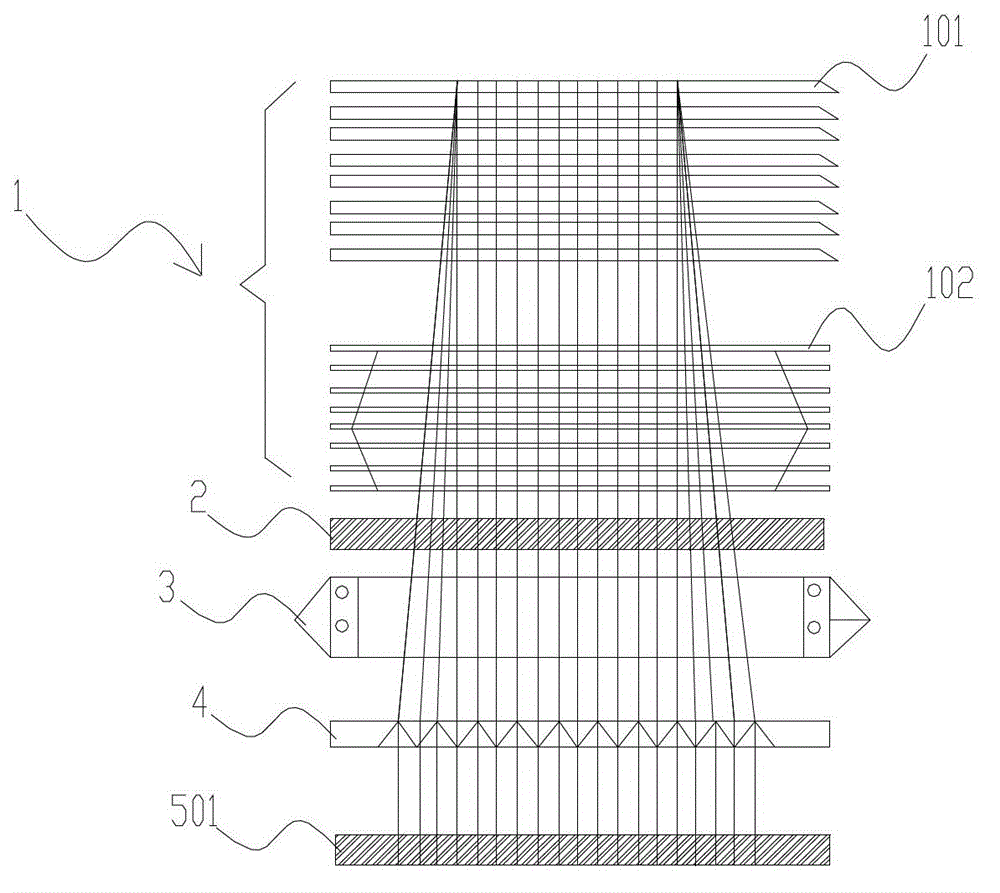

[0033] Such as Figure 1 to Figure 2 As shown, a kind of sizing machine capable of automatic flower arrangement includes a yarn splitting device 1 and a headstock winding device 5, the yarn splitting device 1 is located in front of the headstock winding device 5, and the yarn splitting device 1 and the headstock A pressure roller device 2 , an automatic pattern arrangement device and a telescopic reed 4 are sequentially arranged between the winding devices 5 along the moving direction of the yarn, and the automatic pattern arrangement device is connected with a data processing system 6 .

[0034] Wherein, the pressure roller device 2 includes a movable upper roller 201 and a lower roller 202, and a gap is formed between the upper roller 201 and the lower roller 202. The top roller 201 is made of rubber elastic material, and the bottom roller 202 is made of stainless steel metal material. The automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com