Sizing machine with automatic pattern arranging function and automatic pattern arranging method implemented by sizing machine

A technology of automatic rowing and sizing machine, applied in the direction of processing textile material yarn guide device, liquid/gas/vapor yarn/filament processing, processing textile material carrier, etc. It can improve production efficiency and utilization rate, rational structure and save labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below:

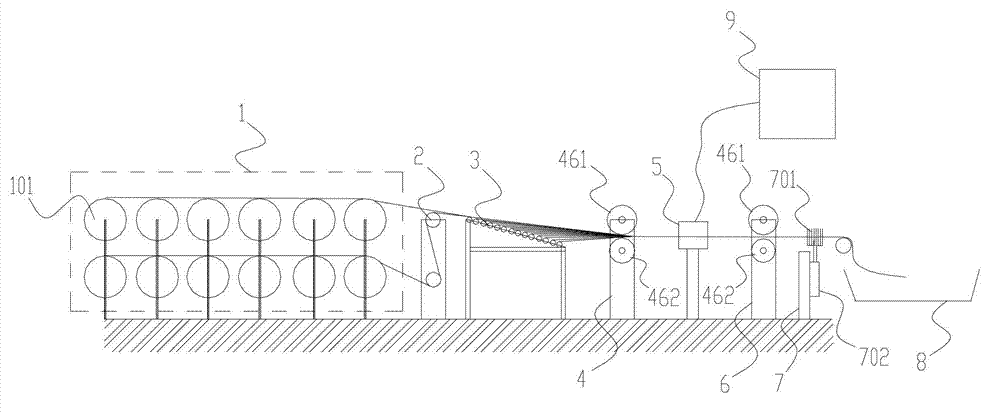

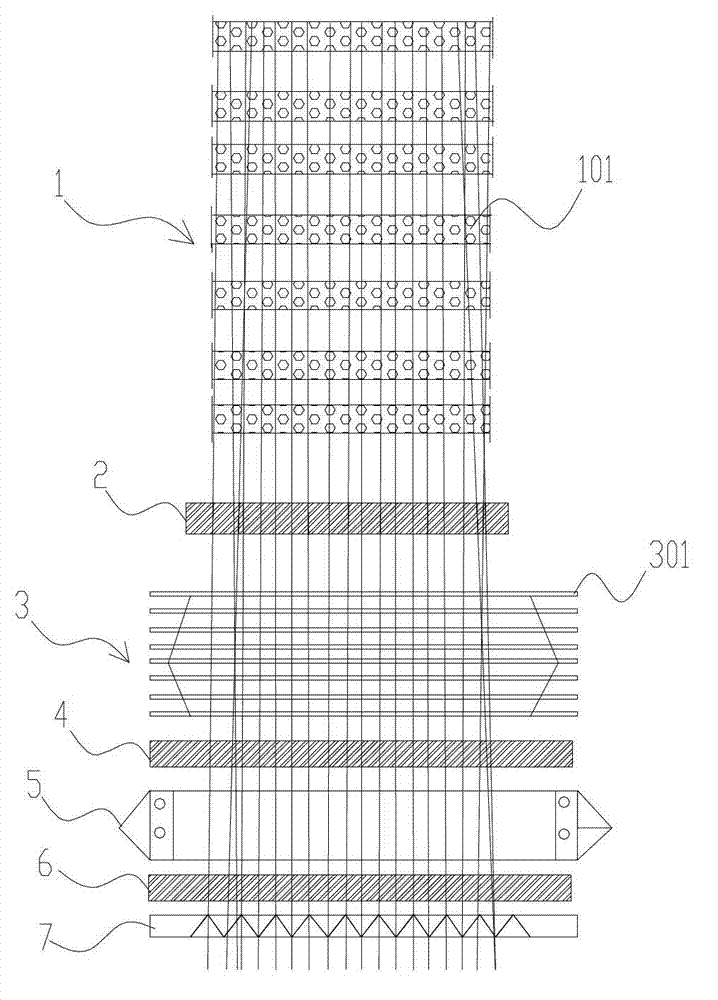

[0033] Such as Figure 1 to Figure 2 As shown, a kind of sizing machine with automatic flower arrangement function, comprises warp creel device 1 and size tank 8, and described warp creel device 1 is placed in front of size tank 8, and the warp creel device 1 and size tank 8 Along the moving direction of the yarn, a color splitting device 3, a first pressure roller device 4, an automatic flower arrangement device, a second pressure roller device 6 and a shaping reed device 7 are arranged in sequence, and the automatic flower arrangement device and the data processing system 9 phase connections.

[0034] Wherein, the color splitting device 3 includes a bracket and a plurality of splitting rods 301, and the splitting rods 301 are installed on the bracket. The first press roller device 4 and the second press roller device 6 both include a movable upper roller 461 and a lower roller 462, and a gap is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com