Test system for heat exchange of internal cooling oil duct of internal-combustion engine piston

A test system, internal combustion engine technology, applied in the direction of internal combustion engine testing, etc., can solve the problems that the vibration distribution of cooling oil cannot be photographed, the shooting angle is not good, and the vibration distribution of cooling oil is not very accurate, etc., so as to achieve convenient observation and wide observation range , the effect of long travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific implementation of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

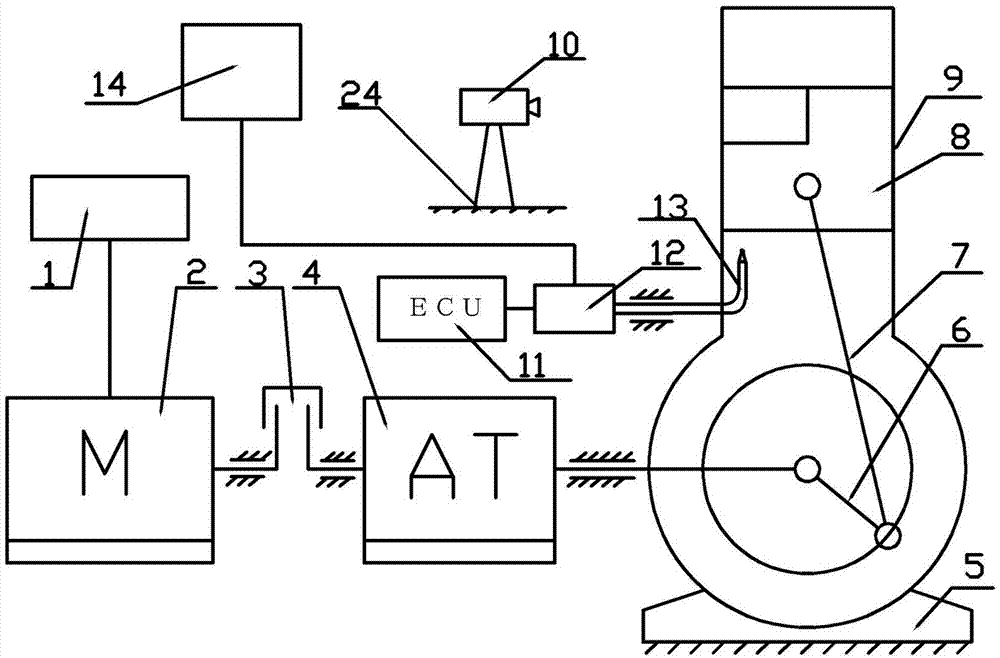

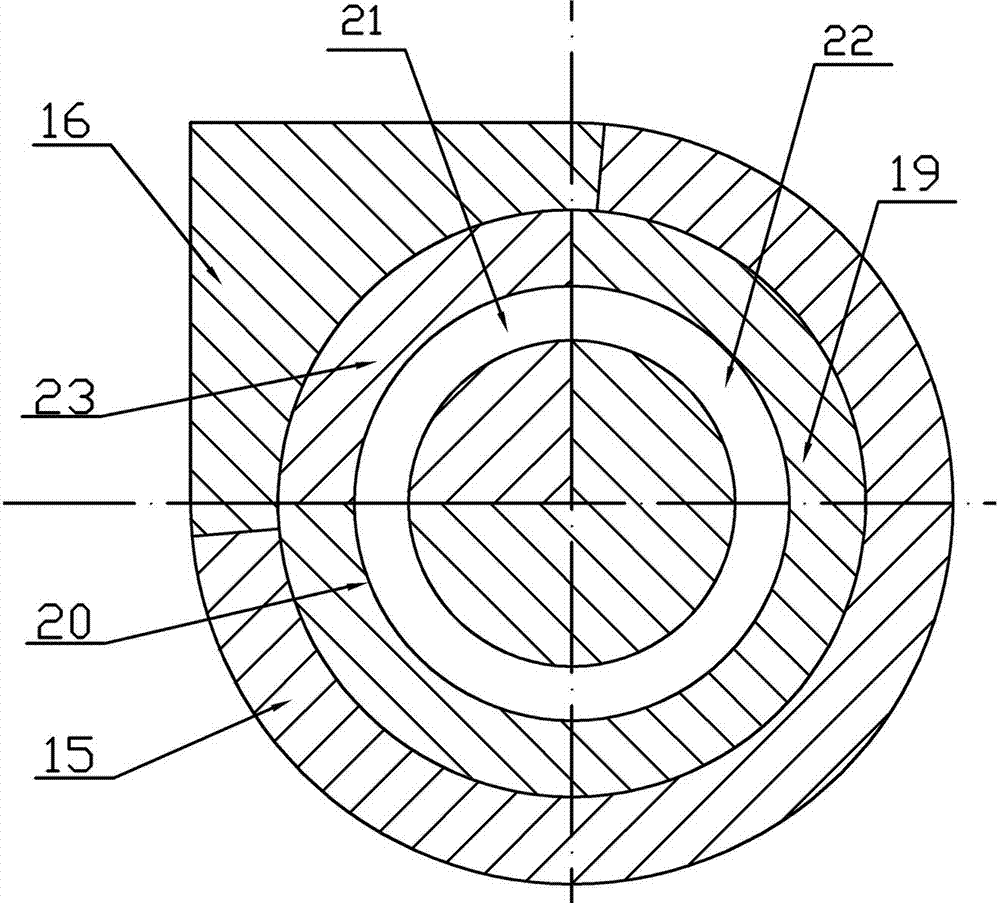

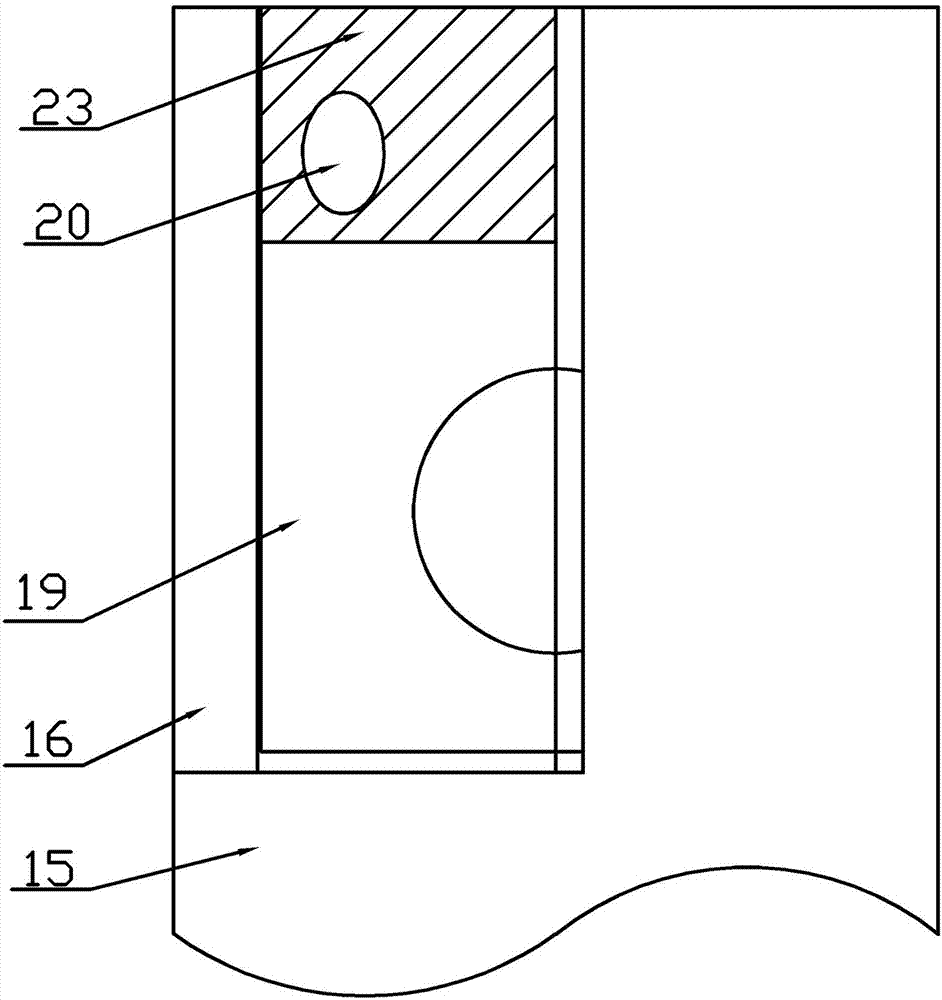

[0057] Internal combustion engine piston internal cooling oil channel heat transfer test system, including special structure piston and cylinder liner, crankshaft connecting rod mechanism to simulate piston movement, base support device, high-speed photography equipment, control fuel injection system and power transmission system. Through the special structure of the piston and cylinder liner, the section of the internal cooling oil passage and a part of the internal cooling oil passage can be observed intuitively. The power is output by the motor and transmitted to the crankshaft through the clutch gearbox, and the crankshaft drives the piston to move in the cylinder liner. The cooling oil is sprayed into the oil inlet hole of the internal cooling oil passage by the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com