Electrocorrosion acceleration test method for DC porcelain insulator iron cap

A technology of porcelain insulators and test methods, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of no test methods, etc., and achieve improved operation safety, good equivalence and repeatability, The effect of strict steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

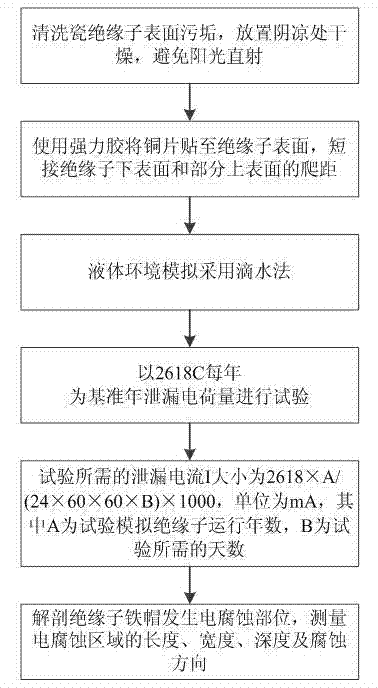

[0025] The design method of the iron cap zinc ring of the DC porcelain insulator of the present invention, concrete implementation steps are as follows figure 1 shown

[0026] 1) Clean the dirt on the surface of the porcelain insulator, place it in a cool place to dry, and avoid direct sunlight;

[0027] 2) In order to facilitate the accelerated electrical corrosion test of the iron cap, the copper sheet is attached to the surface of the insulator with super glue, and the creepage distance between the lower surface of the insulator and part of the upper surface is shorted. The distance between the copper sheet electrode and the iron cap should be 5~ 8cm, this distance refers to the creepage value from the copper sheet electrode to the iron cap along the surface of the insulator. A sealant needs to be coated on the copper electrode to prevent the copper electrode from detaching from the surface of the insulator under the infiltration of water flow.

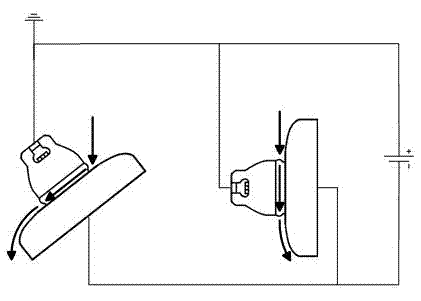

[0028] 3) if figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com