A pump installation inspection method

An inspection method and inspection point technology, applied in pump testing, liquid variable capacity machinery, machines/engines, etc., can solve problems such as unsatisfactory coaxiality, long distance between pump flanges, and low calibration success rate. To achieve the effect of saving manpower, reducing rework, and improving the success rate of calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Technical solution of the present invention is:

[0041] The pump installation inspection method of the present invention comprises the following steps:

[0042] a. The first calibration of the pump

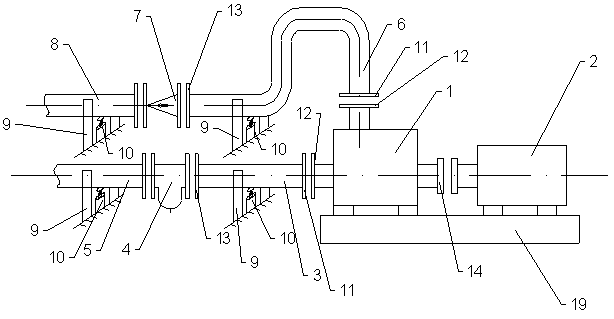

[0043] see now figure 1 , figure 1 It is a schematic diagram of the connection structure between the pipeline and the pump in the embodiment of the present invention. After the basic acceptance of the pump is completed, a grouting is done after the pump equipment is in place, and the first calibration of the pump is carried out.

[0044] b. The second calibration of the pump

[0045] After the pump equipment is in place and the foundation 20 of the pump equipment is fully settled, the second calibration of the pump is performed, and then the second grouting is performed, and the piping installation of the first section of the pump inlet and outlet pipe 3 and the first section of the pump outlet pipe 6 is carried out.

[0046] c. The third calibration of the pump inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com