Assembly tooling and assembly method of rotary compressor

A technology for rotary compressors and assembling tooling, which is applied to auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problem that the assembly tooling assembly method has not been perfected, and achieves low noise, good reliability, and motor clearance imbalance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

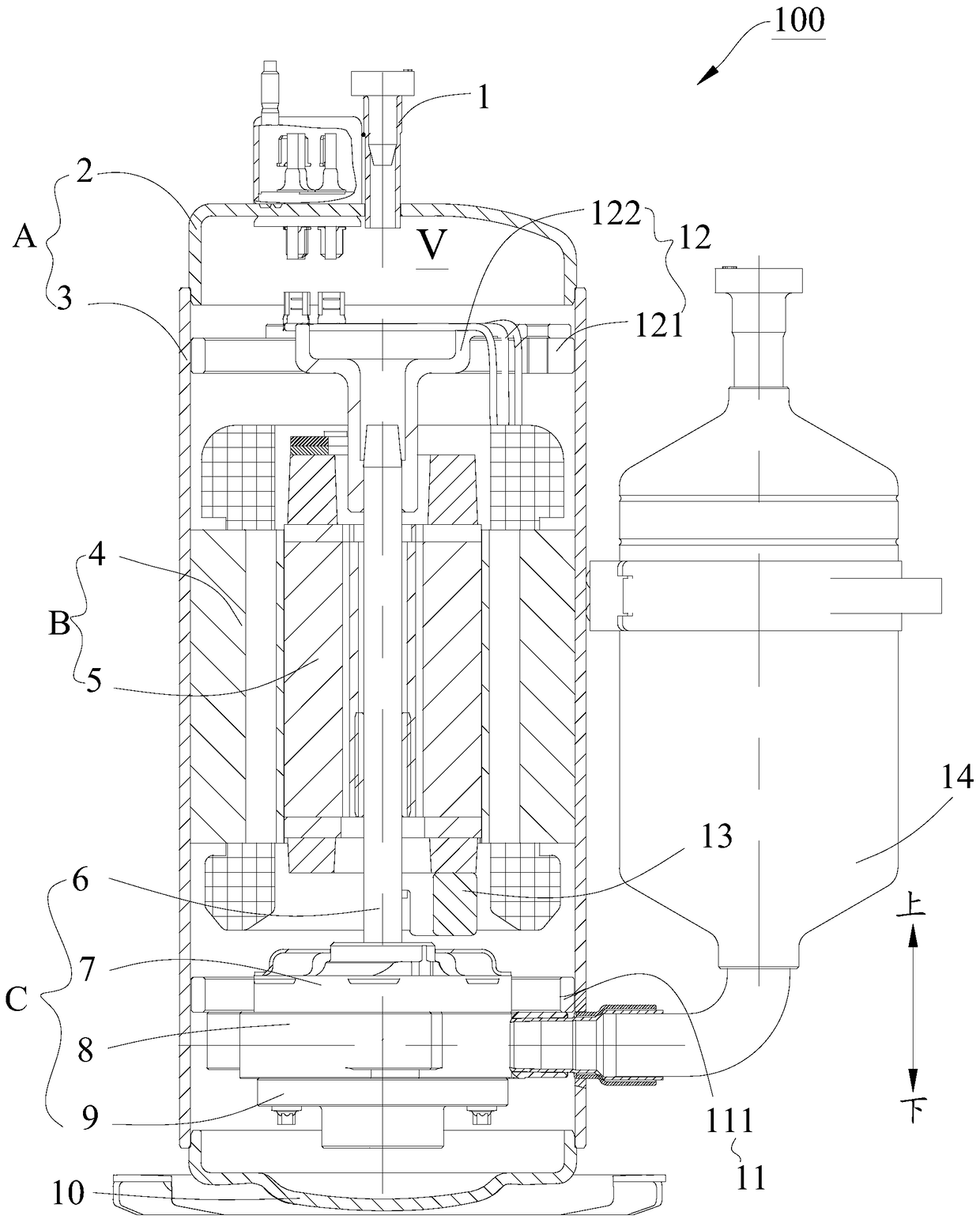

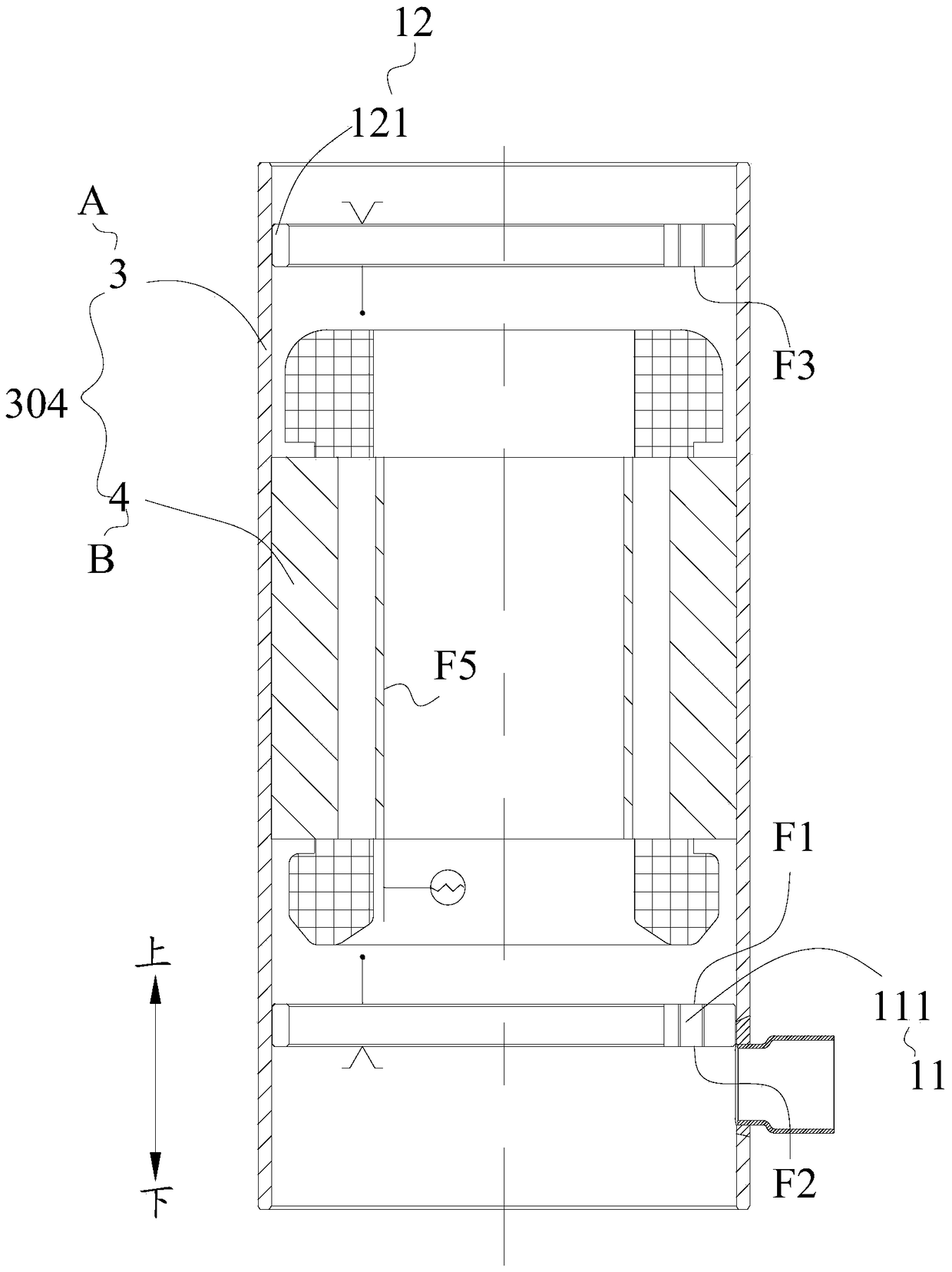

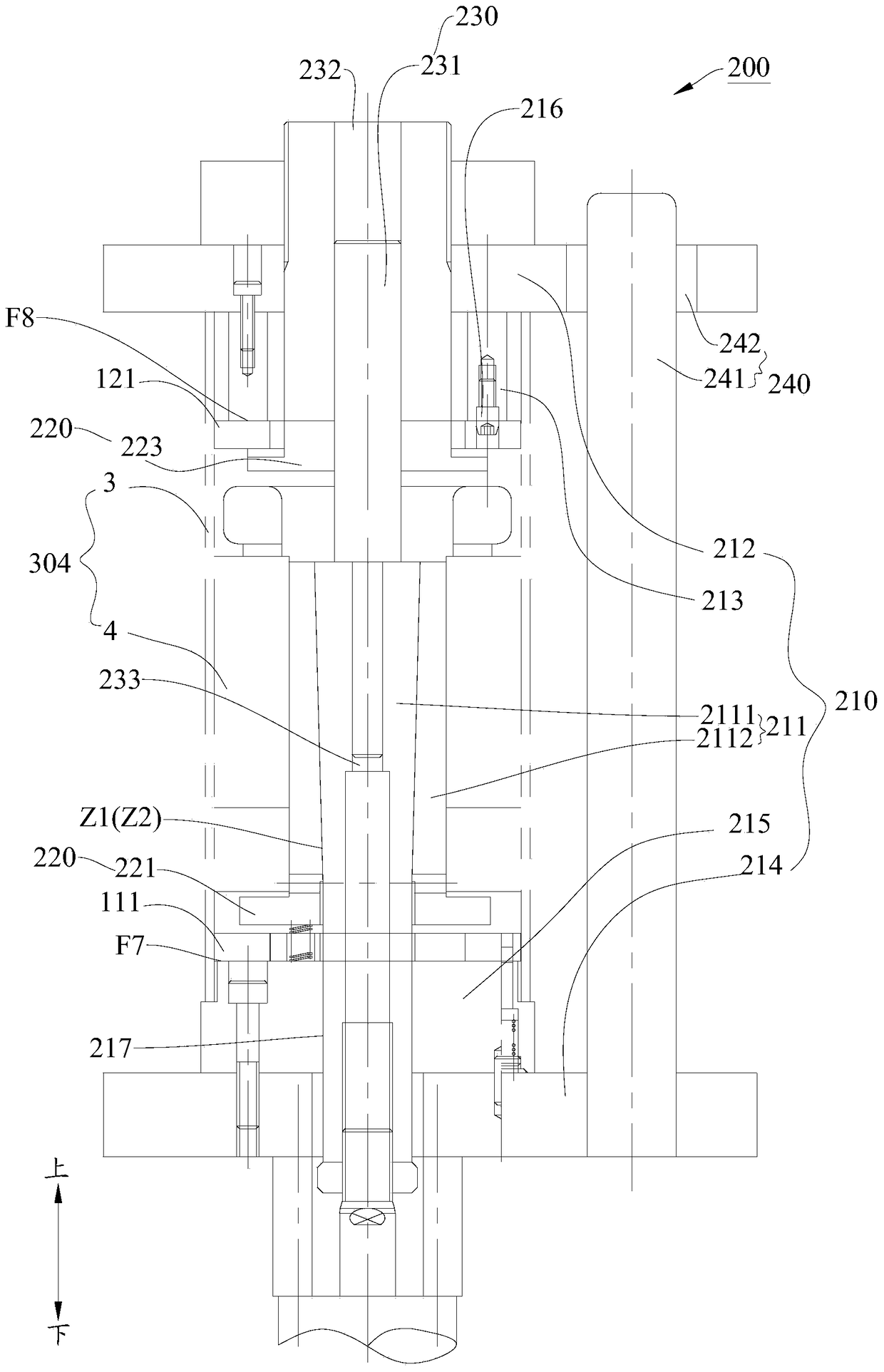

[0105] Such as image 3 As shown, the assembly method steps of the rotary compressor 100 in the first embodiment are as follows:

[0106] S1: respectively position the first frame 111 on the first positioning surface F7 of the lower positioning seat 214, position the second frame 121 on the second positioning surface F8 of the upper positioning seat 212, and position the housing stator assembly 304 Overcoat on the elastic sleeve 2112, and position the lower end surface of the middle housing 3 on the lower positioning seat 214;

[0107] S2: The clamping system 220 is working, wherein the upper clamp 223 on the upper positioning seat 212 moves upwards to clamp the second frame 121 on the upper positioning platform 213, and the upper rigid shaft 2111 of the lower positioning seat 214 moves downward , so as to press the stator inner diameter surface F5 of the housing stator assembly 304 tightly on the outer surface of the elastic sleeve 2112, and clamp the first frame 111 on the ...

Embodiment 2

[0112] Such as Figure 4 As shown, the assembly method steps of the rotary compressor 100 in the second embodiment are as follows:

[0113] S1: respectively position the first frame 111 on the first positioning surface F7 of the lower positioning seat 214, position the second frame 121 on the second positioning surface F8 of the upper positioning seat 212, and position the housing stator assembly 304 Overcoat on the elastic sleeve 2112, and position the lower end surface of the middle housing 3 on the lower positioning seat 214;

[0114] S2: The clamping system 220 works, the first rotary cylinder 222 clamps the first frame 111 on the lower positioning platform 215, and the second rotary cylinder 224 clamps the second frame 121 on the upper positioning platform 213, so that the second The first frame 111 and the second frame 121 are respectively clamped on the lower positioning seat 214 and the upper positioning seat 212; the rigid shaft 2111 moves toward the end where the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com