Reactor and manufacturing method thereof

一种电抗器、构造成的技术,应用在电感/变压器/磁铁制造、电感器、固定电感器等方向,能够解决制造设施成本及空间要求增加等问题,达到低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

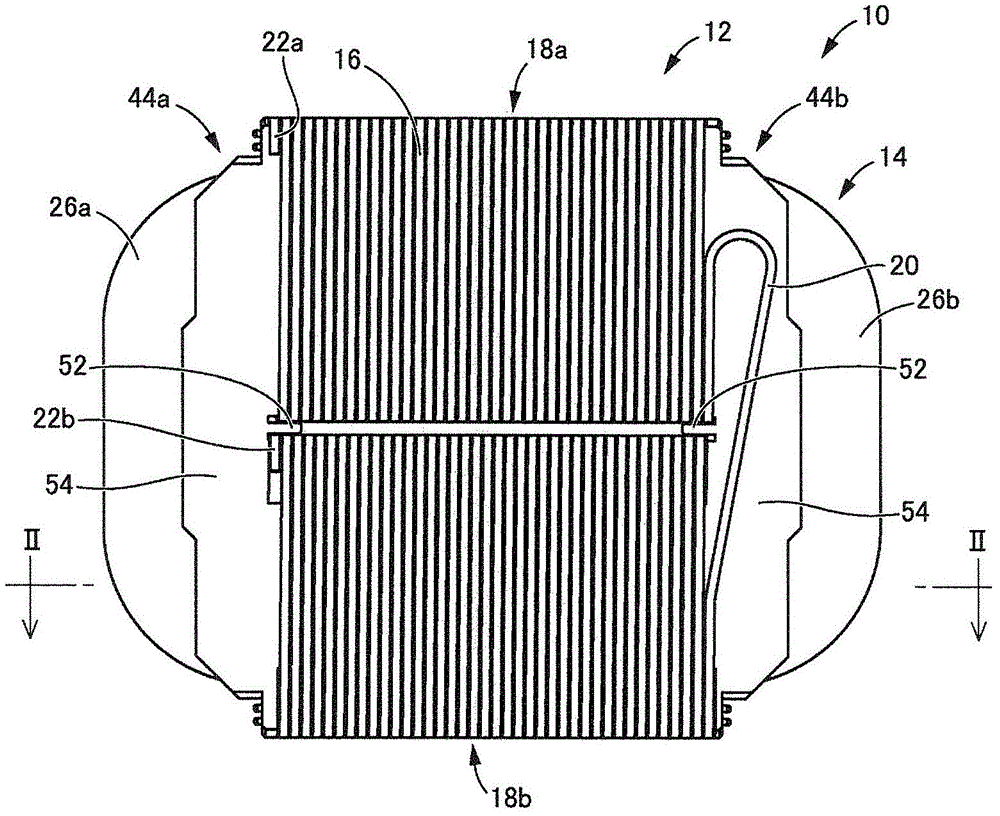

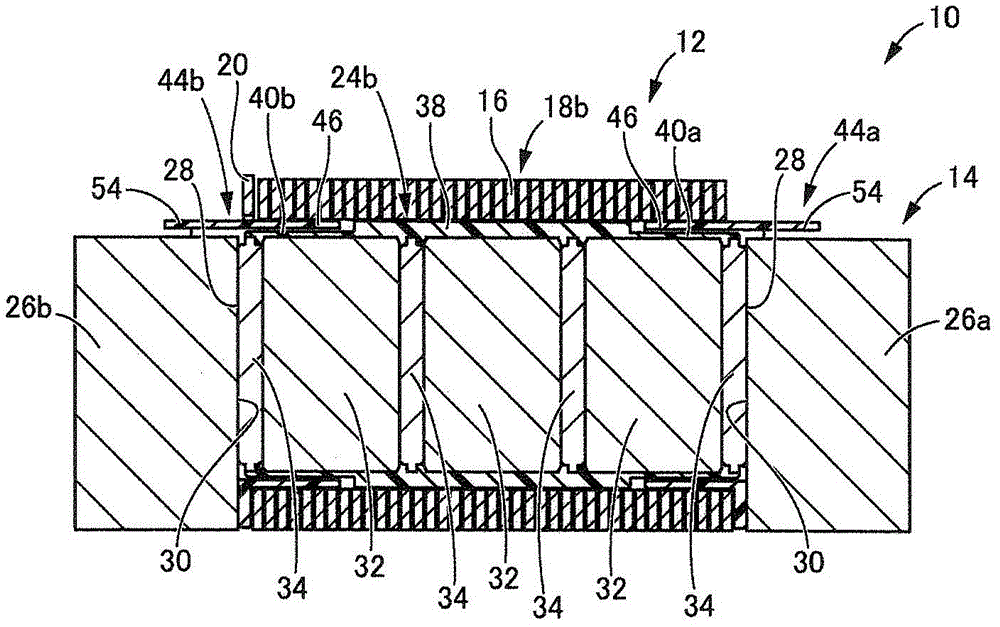

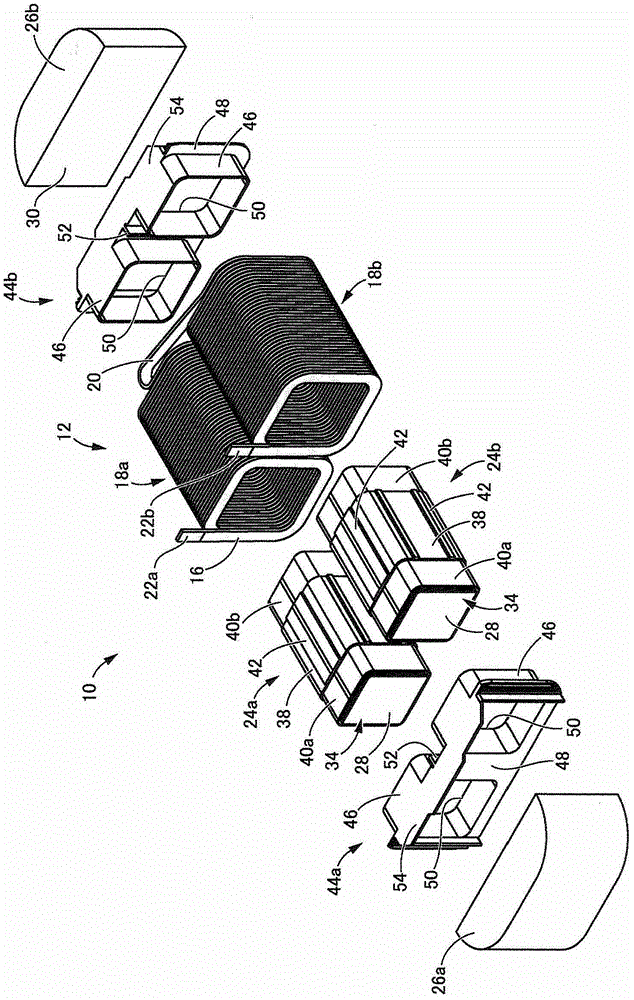

[0035] Figures 1 to 3 A reactor 10 of a first embodiment of the present invention is shown. The reactor 10 includes a coil 12 and an annular core 14 on which the coil 12 is wound. In the following description, the installation side ( figure 2 The lower side in ) is defined as the bottom, and its opposite side is defined as the top.

[0036]The coil 12 includes: a pair of coil elements 18a, 18b formed by winding a continuous winding wire 16 without any joining portion in a spiral shape; and a coil coupling portion 20, The coil coupling part 20 couples the coil elements 18a, 18b. The coil elements 18a, 18b have the same number of turns, and they have a substantially rectangular shape when viewed in the axial direction. The coil elements 18 a , 18 b are arranged side by side so that their axes are parallel to each other, and a portion of the winding wire 16 on one end of the coil 12 is bent into a U shape to form the coil coupling portion 20 . In this configuration, the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com