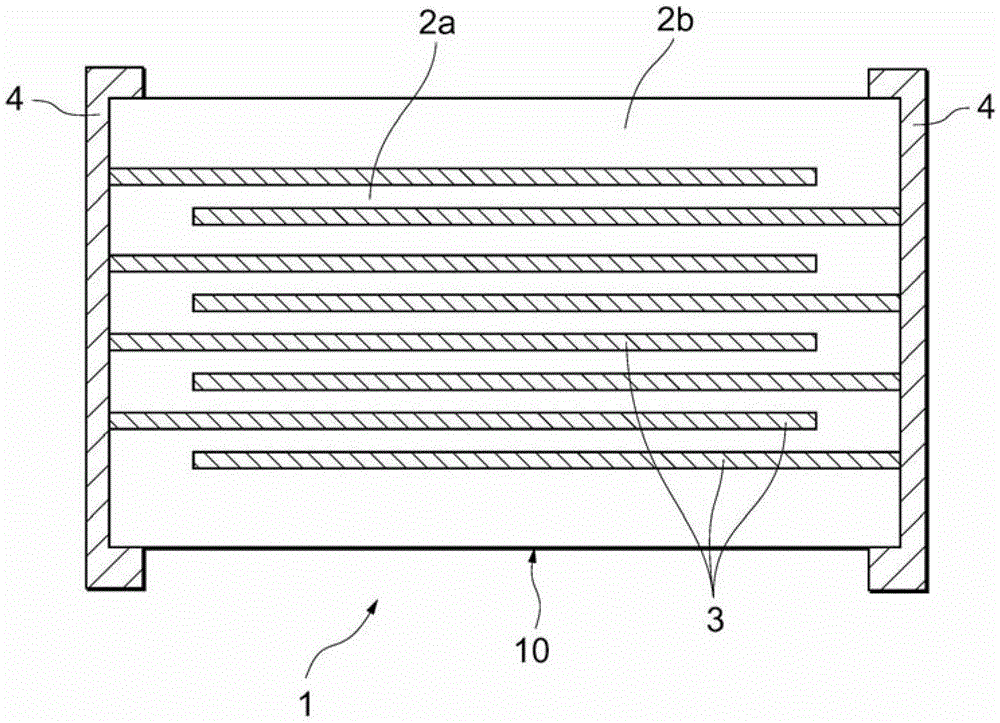

Laminated Ceramic Electronic Components

A technology for electronic components and ceramics, applied in the field of laminated ceramic electronic components, can solve problems such as Ni diffusion, and achieve the effect of high moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0128] [Sample No.a-1~5]

[0129] First, prepare the BaTiO 3 Powder as the main ingredient is ABO 3 raw materials. In addition, MgCO was prepared separately as a raw material of subcomponents 3 As the raw material of Mg oxide, R 2 o 3 The powder is used as the raw material of the oxide of the R element, (Ba 0.6 Ca 0.4 ) SiO 3 (hereinafter referred to as BCG) powder as the raw material of oxides containing Si, MnO powder as the raw material of Mn oxides, V 2 o 5 The powder is used as a raw material of V oxide. In addition, MgCO 3 Included in the dielectric porcelain composition after firing as MgO.

[0130] Next, the above prepared BaTiO 3 Powder (average particle size: 0.20 μm) and subcomponent raw materials were wet pulverized in a ball mill for 15 hours and dried to obtain dielectric raw materials. In addition, the addition amount of each subcomponent is in the dielectric ceramic composition after firing, relative to the main component, that is, BaTiO 3 100 mol...

experiment example 2

[0159] [Sample No.b-1~5]

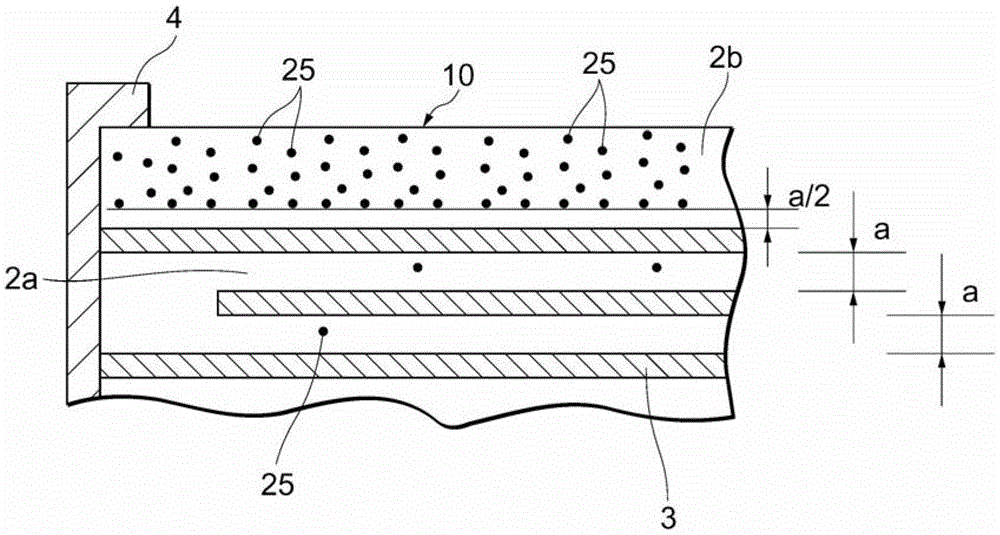

[0160] In addition to preparing BaTiO 3 The average particle size of the powder is 0.50 μm, the thickness of the dielectric layer is 2.5 μm, the thickness of the internal electrode layer is 0.7 μm, and the number of dielectric layers sandwiched by the internal electrode layer is 130, which is the same as that of sample No.a-1~ 5. Green sheets were obtained in the same manner. The heat treatment conditions for green sheets, except for the first firing conditions are heating rate: 200°C / hour, holding temperature: 1250°C, holding time for 2 hours, cooling rate: 200°C / hour, atmosphere gas: humidified N 2 +H 2 Mixed gas (oxygen partial pressure is 1.0×10 -5 Except Pa), samples of multilayer ceramic capacitors were obtained in the same manner as sample No.a-1 to 5.

[0161] [Sample No.c-1~5]

[0162] In addition to preparing BaTiO 3 The average particle diameter of the powder was 0.15 μm, the thickness of the dielectric layer was 0.65 μm, and the thi...

experiment example 3

[0177] [Sample No.a-1~7]

[0178] Sample No.a-6 and a-7 corresponding to the annealing conditions of Table 1 were obtained similarly to the sample No.a-1-5 similarly to Experimental Example 1.

[0179] For sample Nos. a-1 to 7, the measurement of the area ratio of Ni precipitated to the outer layer, the moisture resistance load test, and the high-temperature accelerated life (HALT) test were performed in the same manner as in Experiment 1. The results are shown in Table 4.

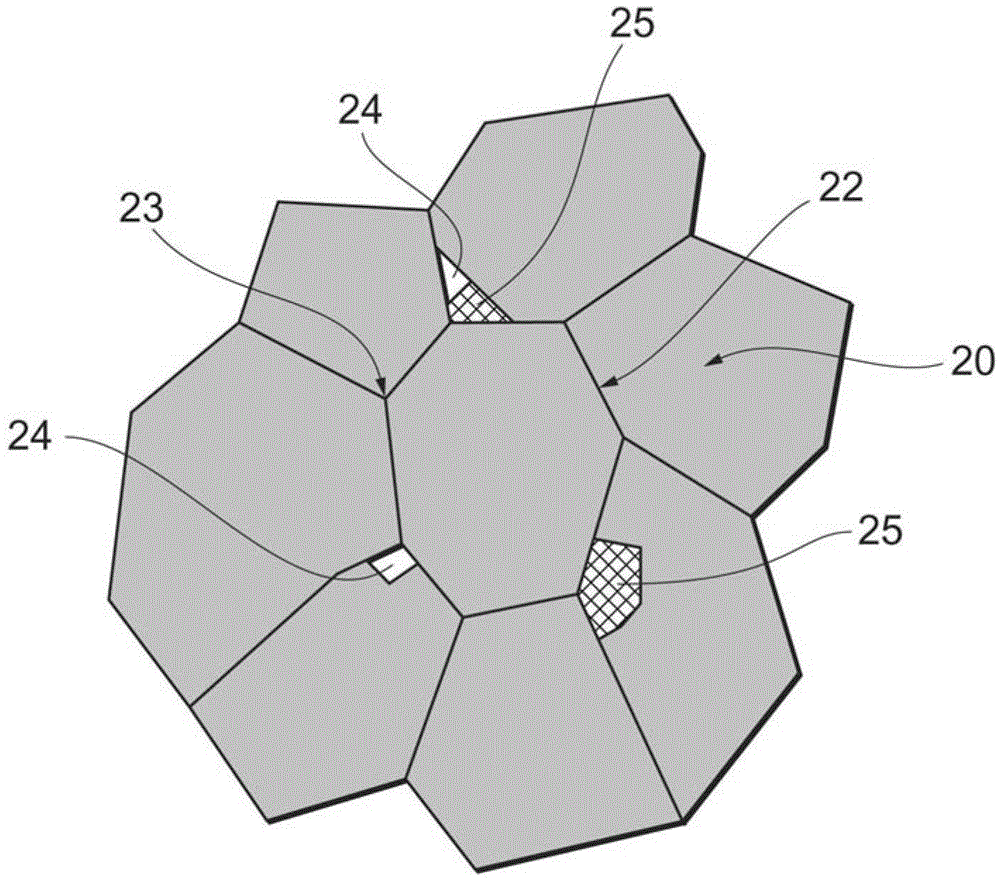

[0180] The measurement of the amount of Ni precipitated in the dielectric layer was performed by the method shown below.

[0181]

[0182] The inner layer region was observed by STEM with 10 fields of view at a magnification of 5000 times. Discrimination between dielectric particles and Ni particles was performed using an EDS device.

[0183] Next, the area ratio of the Ni particles to the dielectric region of the cross-section to be measured is obtained. The results are shown in Table 4.

[0184] [...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com