A Gas Insulated Switchgear Based on In vivo Adsorption

A gas-insulated switch and equipment technology, applied in the setting of switchgear, switchgear, electrical components, etc., can solve the problems of reduced electrical insulation performance, generation of free carbon, inapplicability, etc., and achieve the effect of preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] The gas insulated switchgear of the present invention is a sealed container filled with insulating gas. The airtight container is equipped with at least one pair of electric contact electrodes, particle adsorption electrodes, adsorption device and particle collection device.

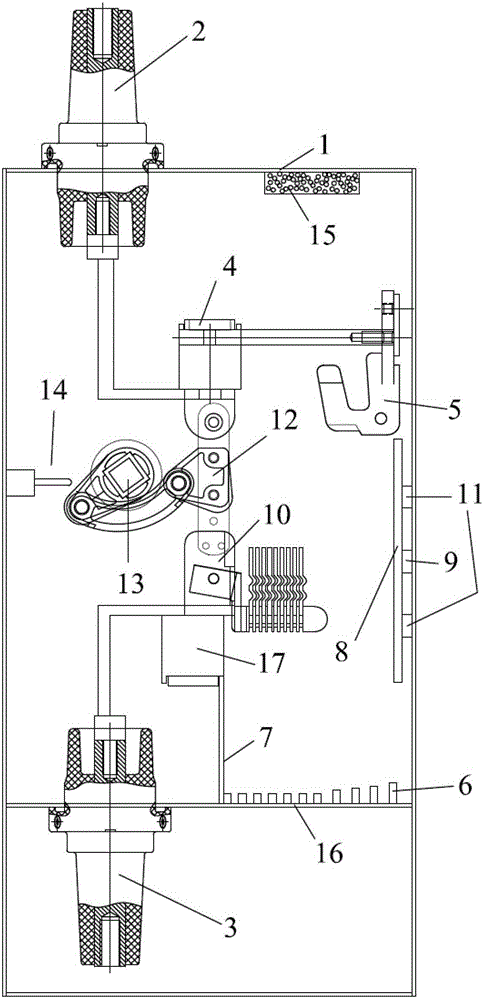

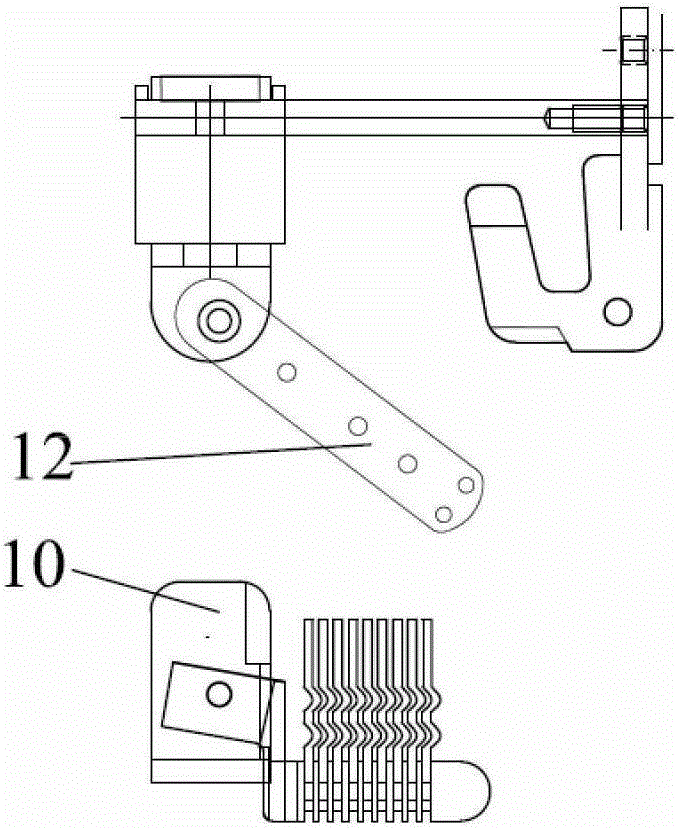

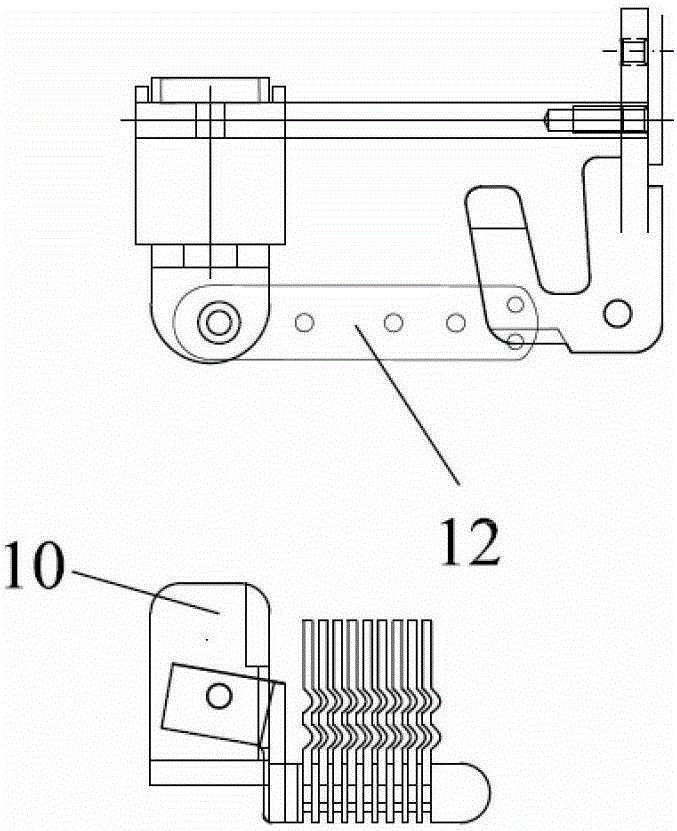

[0023] figure 1 It is a partial sectional view of a gas insulated switchgear according to an embodiment of the present invention. figure 1 A load switch is shown in conduction. Fluorocarbon gas containing carbon elements and nitrogen or CO are packaged in the airtight container 1 2 or a mixture of air, the airtight container 1 has an upper outlet bushing 2, a lower outlet bushing 3, a moving contact seat 4, a grounding contact 5, a moving contact 12, a moving contact operating shaft 13, a static contact and The arc extinguishing grid 10, the particle isolation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com