Corn harvester and edulcoration and screening device for grains of corn harvester

A corn harvester and screening device technology, which is applied to harvesters, threshing equipment, agricultural machinery and implements, etc., can solve the problem that the sieve body cannot vibrate and screen grains, and achieve the effects of compact structure, reduced loss rate, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

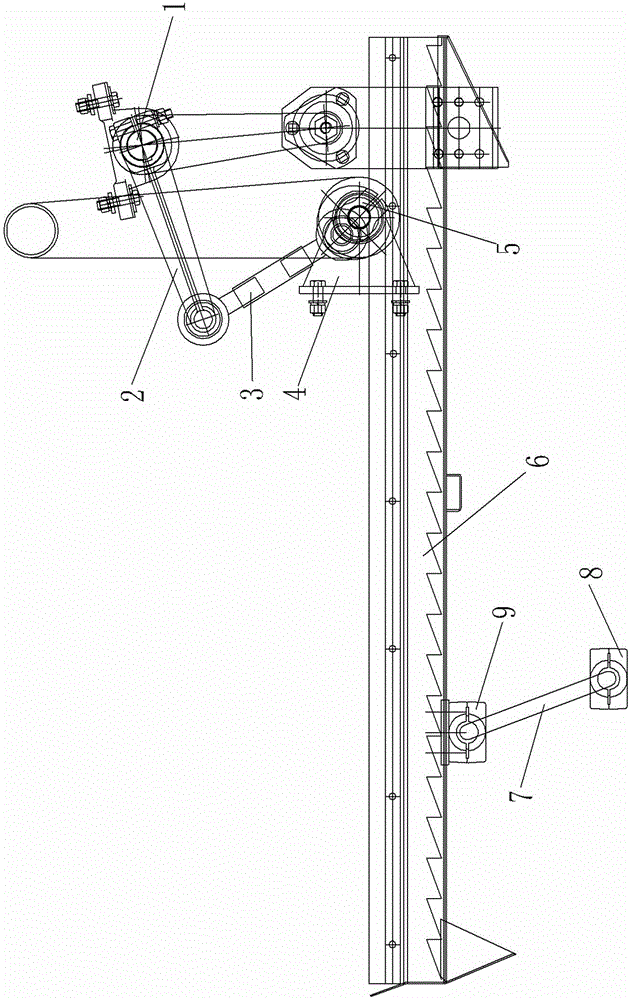

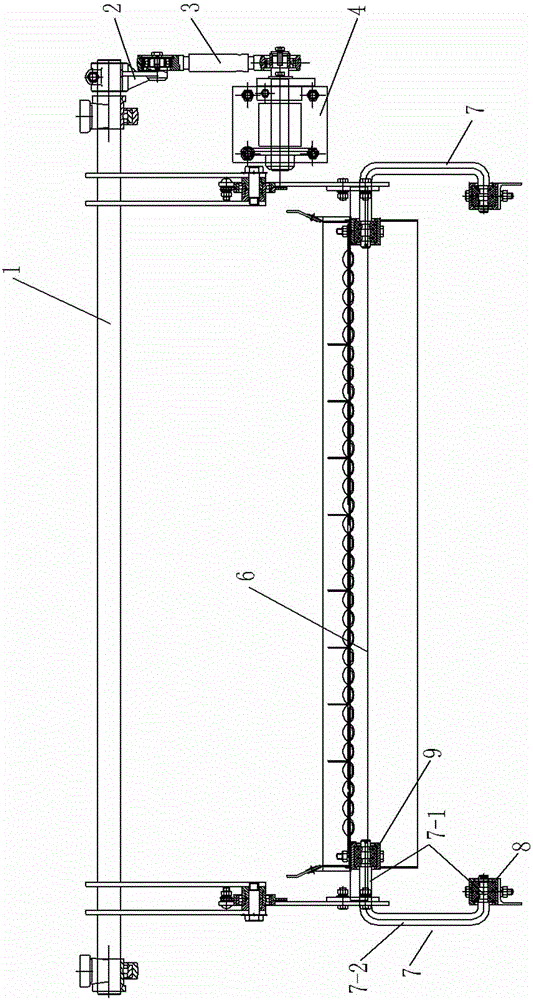

[0020] An example of a corn harvester is Figure 1~2 Shown: It includes the main frame and the corn harvesting device, peeling machine and grain removal and screening device set on it. The grain removal and screening device includes the screening device frame and the sieve body 6 extending forward and backward in the length direction. The sieve body 6 passes through the movement The mechanism and follow-up mechanism can produce front and rear movement and up and down movement and are assembled on the frame of the screening device. The movement mechanism and follow-up mechanism are arranged at the front and rear ends of the screen body at intervals along the front and rear directions. The movement mechanism and follow-up mechanism are separately located in The upper and lower sides of the sieve body. The motion mechanism includes a drive shaft 1 set on the frame, the rotation axis extends in the left and right directions and is driven by a corresponding power source. The drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com