Vegetable and fruit mask machine

A facial mask machine and facial mask technology, applied in the direction of cosmetics, skin care preparations, cosmetic preparations, etc., can solve the problems of cumbersome operation, easy water ingress, and shortened machine life, and achieve simple operation and cleaning, no hygienic dead ends, and improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

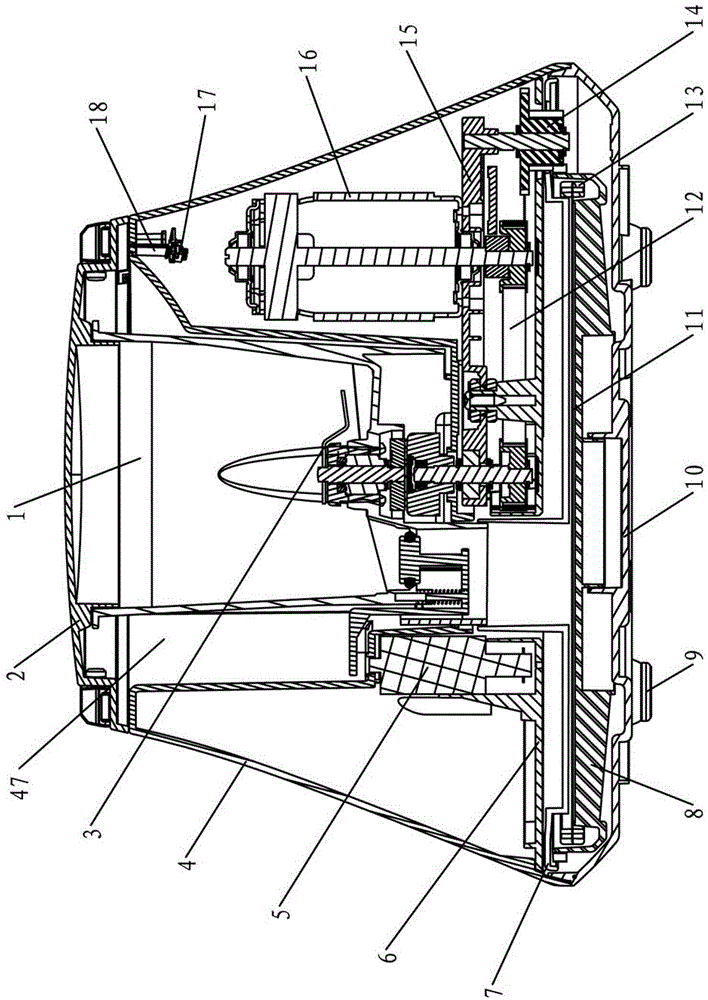

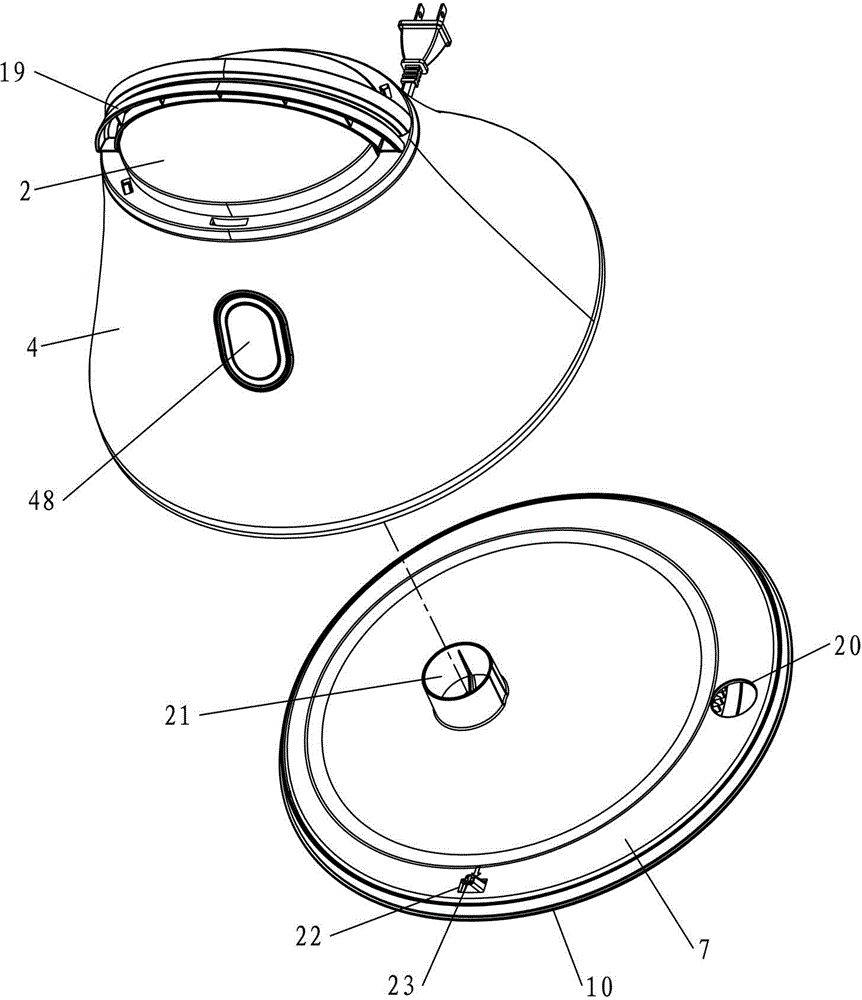

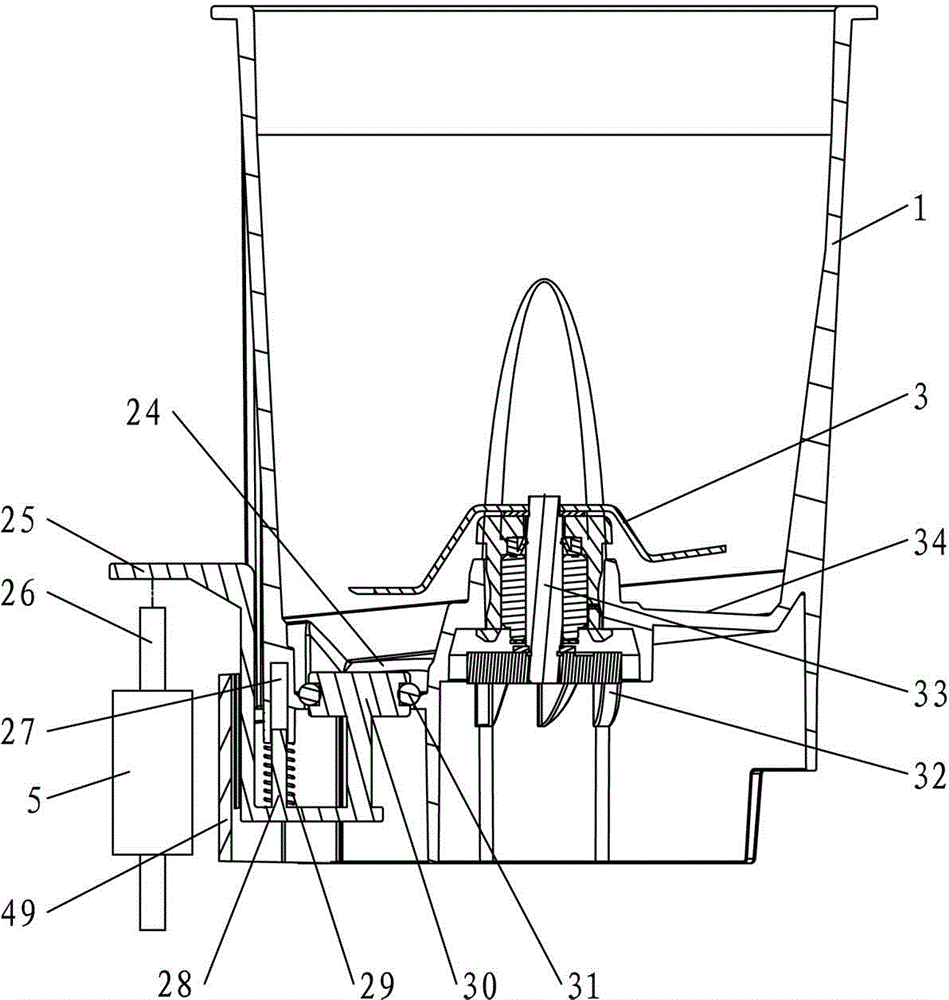

[0041] Embodiment one, see Figure 1 to Figure 4 , Figure 6 to Figure 8 as well as Figure 12 to Figure 15 Shown, a kind of vegetable and fruit facial mask machine comprises a stirring host and a mask forming host, the stirring host includes a stirring cup 1 with a juice outlet 24 at the bottom, and a controller for controlling the automatic opening and closing of the juice outlet 24, and the facial mask forming The main engine includes a scraper 7, a bottom shell 10 and a mask forming tray 8. The scraper 7 is provided with a feeding port 21 connected to the juice outlet 24 and the mask forming tray 8. The scraper 7 is arranged above the mask forming tray 8, and the mask forming tray 8 Set on the bottom shell 10.

[0042] The controller includes an electric control drive device, a juice leakage control lever 25 and a sealing plug, the sealing plug is arranged in the juice outlet 24, a reset spring 29 is connected between the juice leakage control lever 25 and the stirring c...

Embodiment 2

[0060] Embodiment 2, the difference from Embodiment 1 is: the transformation of the form of the paper pressing part and the scraper, see Figure 9 and Figure 10 As shown, the flat net (that is: the filter component) is replaced by a pressure ring 51, and the inner ring of the bottom of the scraper 7 corresponding to the pressure ring 51 is provided with a scraper 52 or a groove 53 (see Figure 11 shown).

Embodiment 3

[0061] Embodiment three, the difference with embodiment one is: see Figure 5 As shown, the electronically controlled driving device is a juice output control motor 60, the juice output control motor shaft 61 is connected with an eccentric cam 62, and the outer periphery of the eccentric cam 62 is in transmission connection with the outer end of the juice leakage control rod 25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com