Flexible bending tube die of ball-and-socket joint structure

A technology of ball and socket joints and ball joints, which is applied in the field of trial production of automobile intake pipes, can solve the problems of short cycle, long cycle of equipment installation and debugging, and high precision, and achieve the effects of saving trial production costs, shortening trial production cycle, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

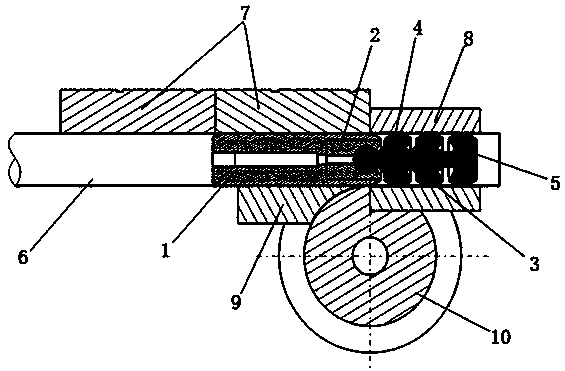

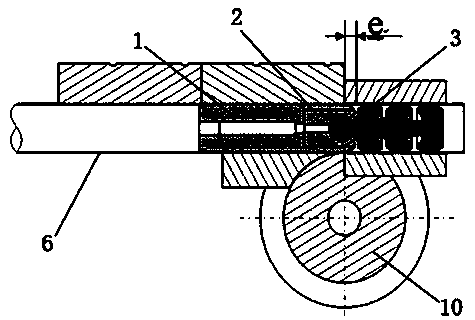

[0020] As shown in Table 1, this time the stainless steel tube is Φ114X2mm, the curved inner fillet R is 150mm, R / D≈1.3, S / D≈1 / 60, and the number of ball joints selected is 3.

[0021]

[0022] Note: 1.N—means that the mandrel can not be used (that is, the elbow without core); 2.H—means that the hard mandrel elbow can be used; 3.F—means that the soft mandrel elbow needs to be used, the number behind Is the recommended number of pitches

[0023] The specific process steps of stainless steel elbow are as follows:

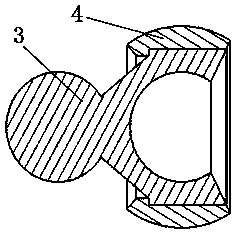

[0024] 1. Design and manufacture the soft elbow mould with ball joint structure according to the above requirements, with 3 ball joints;

[0025] 2. According to the ratio of 10:3, mix the stainless steel forming oil with the special extreme pressure agent for stainless steel, and then apply it evenly on the surface of the ball and socket core rod and the inner surface of the stainless steel tube;

[0026] 3. Put the stainless steel tube 6 to be bent on the ball and socket cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com