Grinding and special regrinding methods for cutters of ring flakers

A planer and cutting tool technology, which is applied to cutting tools for planer/slotting machines, cutting tools for lathes, planing machines, etc., which can solve the trouble of tool regrinding and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

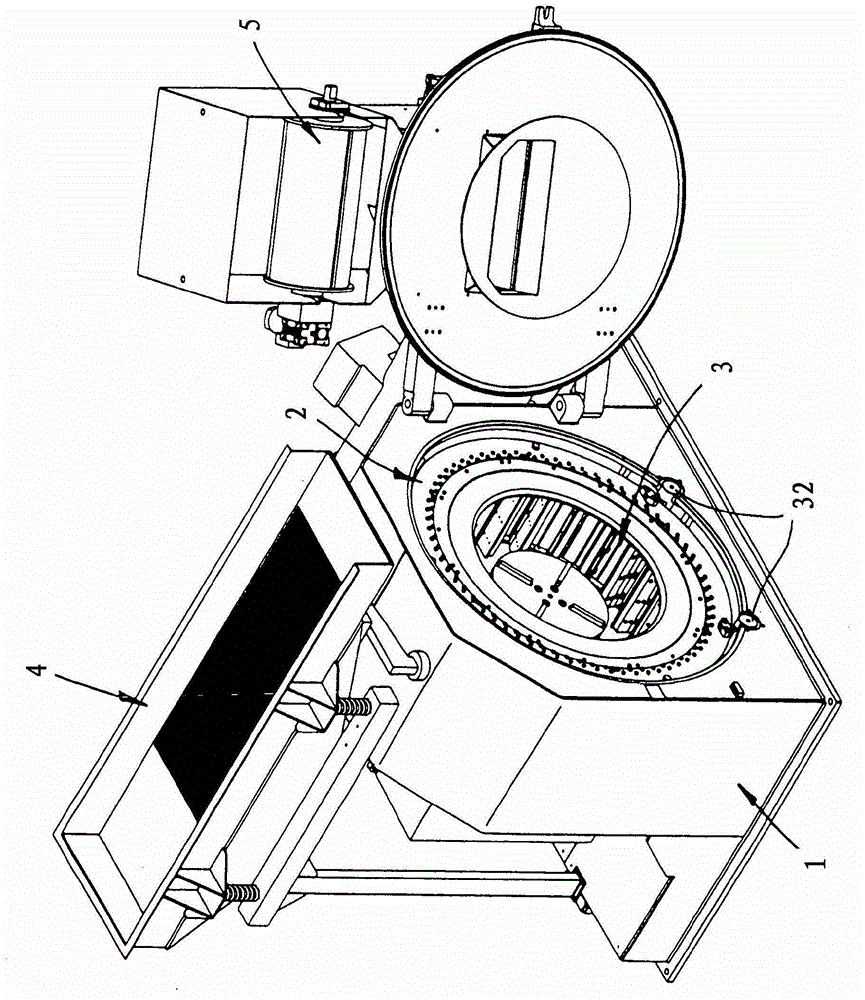

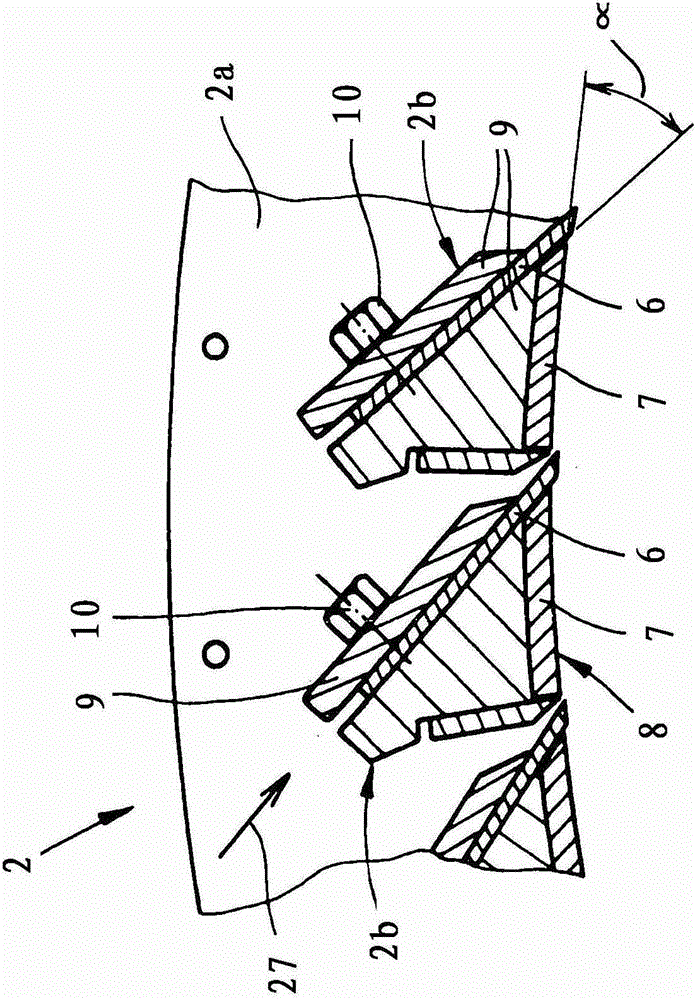

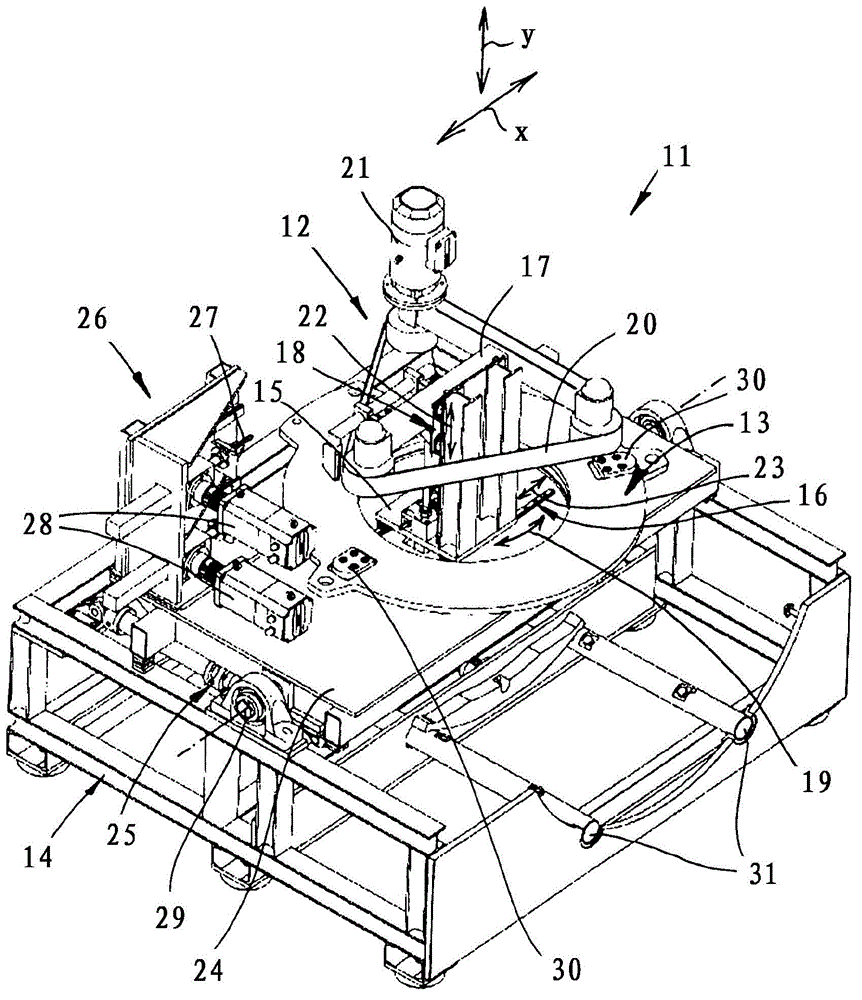

[0028] figure 1 shows a particular embodiment of a flaker as a ring flaker for flakes or comminution of wood, in particular for the production of wood chips or similar materials. Arranged in the housing 1 is a rotating (outer) knife ring 2 on the one hand and an impact wheel 3 rotating inside the knife ring on the other hand. The knife ring 2 and the impact wheel 3 are driven via suitable shafts. Details are not shown in the figure. Typically, the knife ring 2 on the one hand and the impact wheel 3 on the other are counter-rotating. figure 1 A ring flaker is shown, the front of the housing of which is open, so that in particular the knife ring 2 and the impact wheel 3 can be seen inside the housing. Wood is supplied as bulk material, for example in the form of wood chips. This bulk material enters the interior of the ring flaker via an upper conveying chute 4 and the corresponding front deflection 5 , and thus enters the inner chamber formed in the interior of the impact w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com