Olive oil deep processing equipment

An olive oil and equipment technology, which is applied to the processing field of vegetable raw materials, can solve the problems of inconvenience, easy rolling of olives to the ground, trouble, etc., and achieves the effect of convenient feeding and guaranteed crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

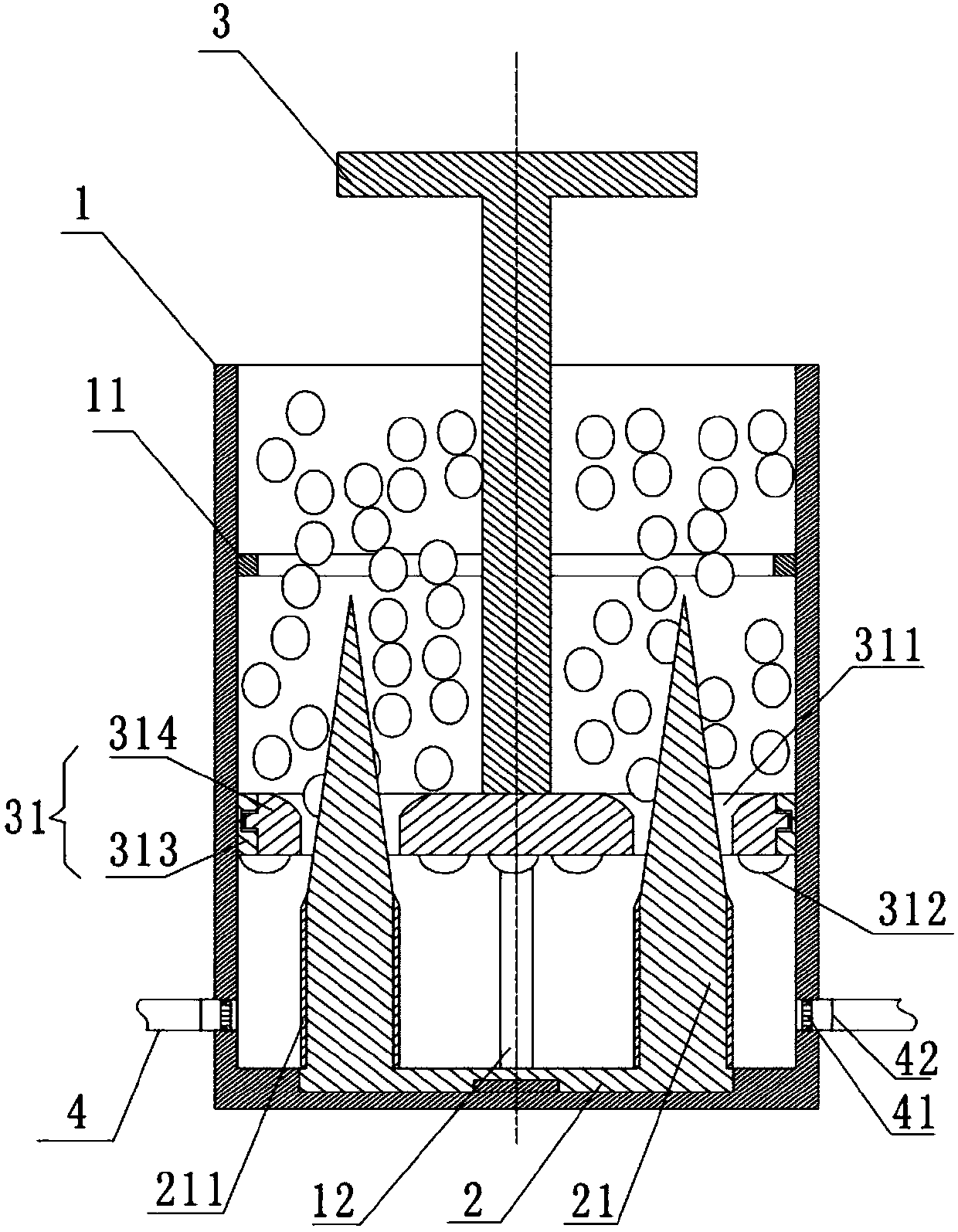

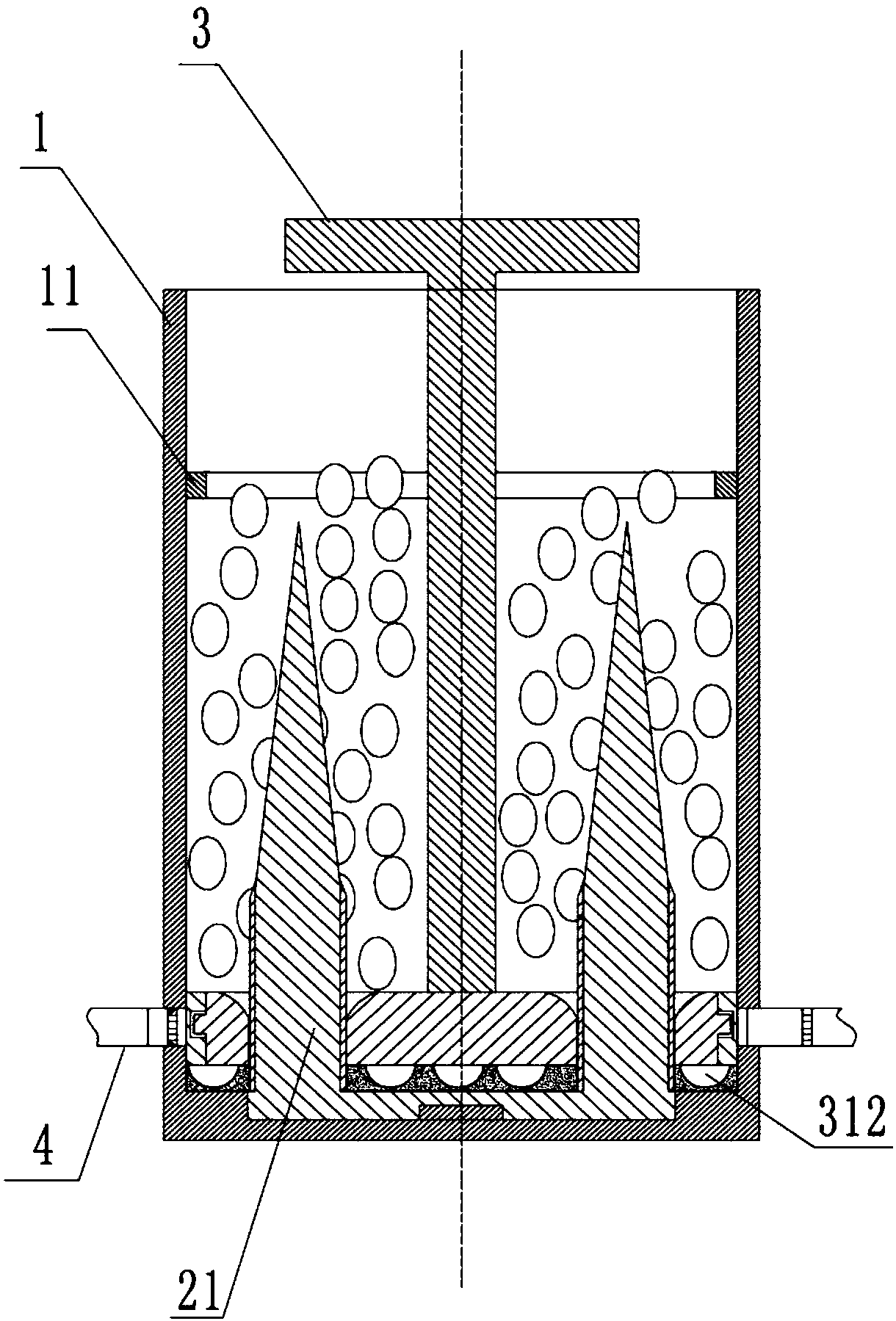

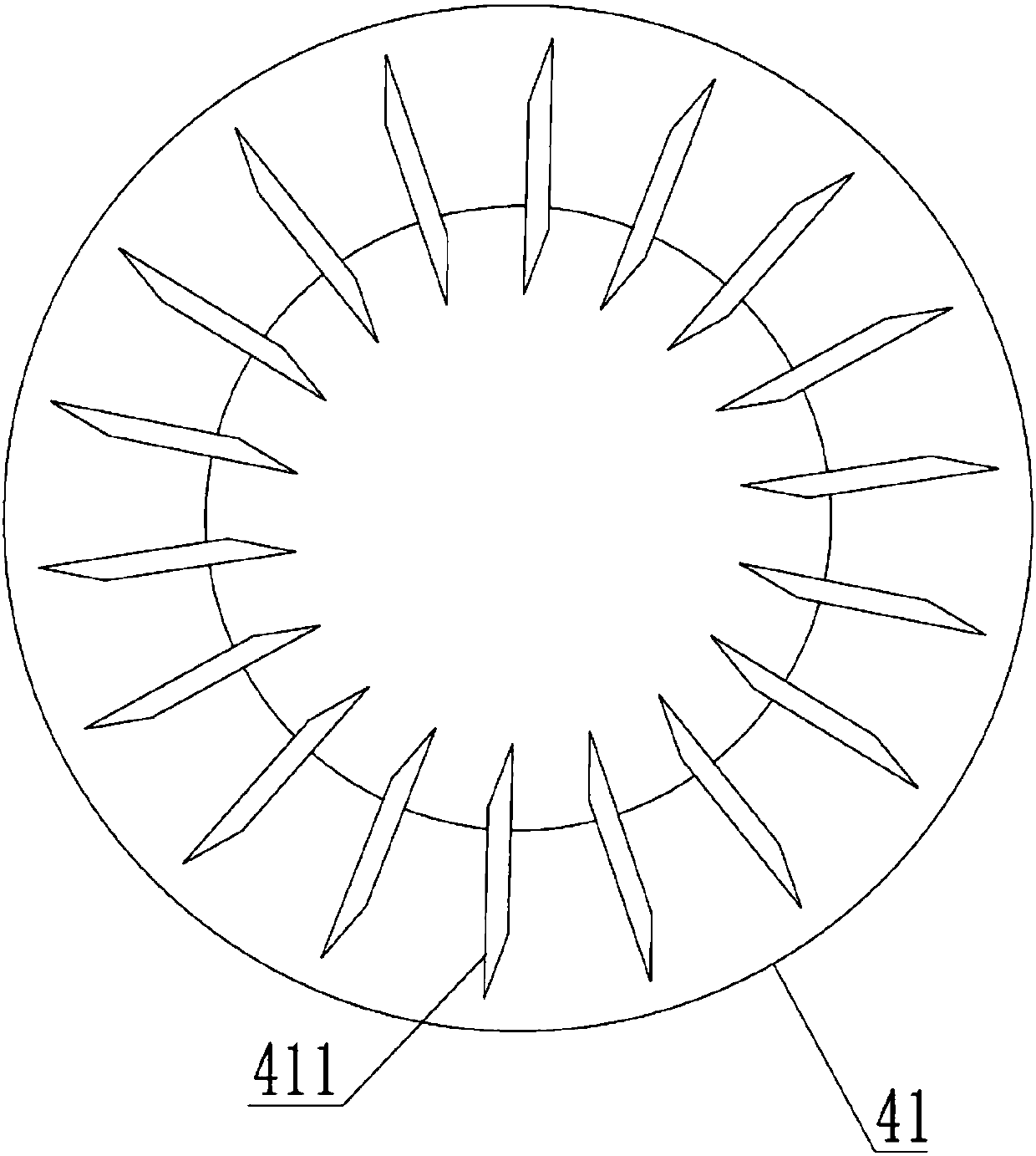

[0022] Instructions attached figure 1 , figure 2 and image 3 The reference signs in include: processing barrel 1, limit ring 11, chute 12, rotating disk 2, guide rod 21, sealing layer 211, push rod 3, push plate 31, feeding hole 311, ball 312, outer ring 313 , Inner disc 314, discharge pipe 4, secondary processing ring 41, hard filter screen 42, blade 411.

[0023] Such as figure 1 and figure 2 Shown, in order to achieve the above object, basic scheme of the present invention is as follows:

[0024] Olive oil deep processing equipment includes a processing barrel 1, a rotating structure and a pushing structure for pushing olives; the rotating structure includes a rotating disk 2 and two guide rods 21 fixedly connected to the rotating disk 2, and the rotating disk 2 and the processing barrel The inner bottom surface of 1 is rotationally connected; the pushing stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com