Discharging device for planetary ball grinding mill and discharging control method

A planetary ball mill and control method technology, which is applied in the fields of mechanical force activation, grinding, pulverization, mechanochemical and mechanized alloy processing, can solve the problem that the ground materials cannot be screened and refined, continuous discharge cannot be realized, and wear is prone to occur. and other problems, to achieve the effect of improving the grinding effect, improving the maintenance efficiency and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings.

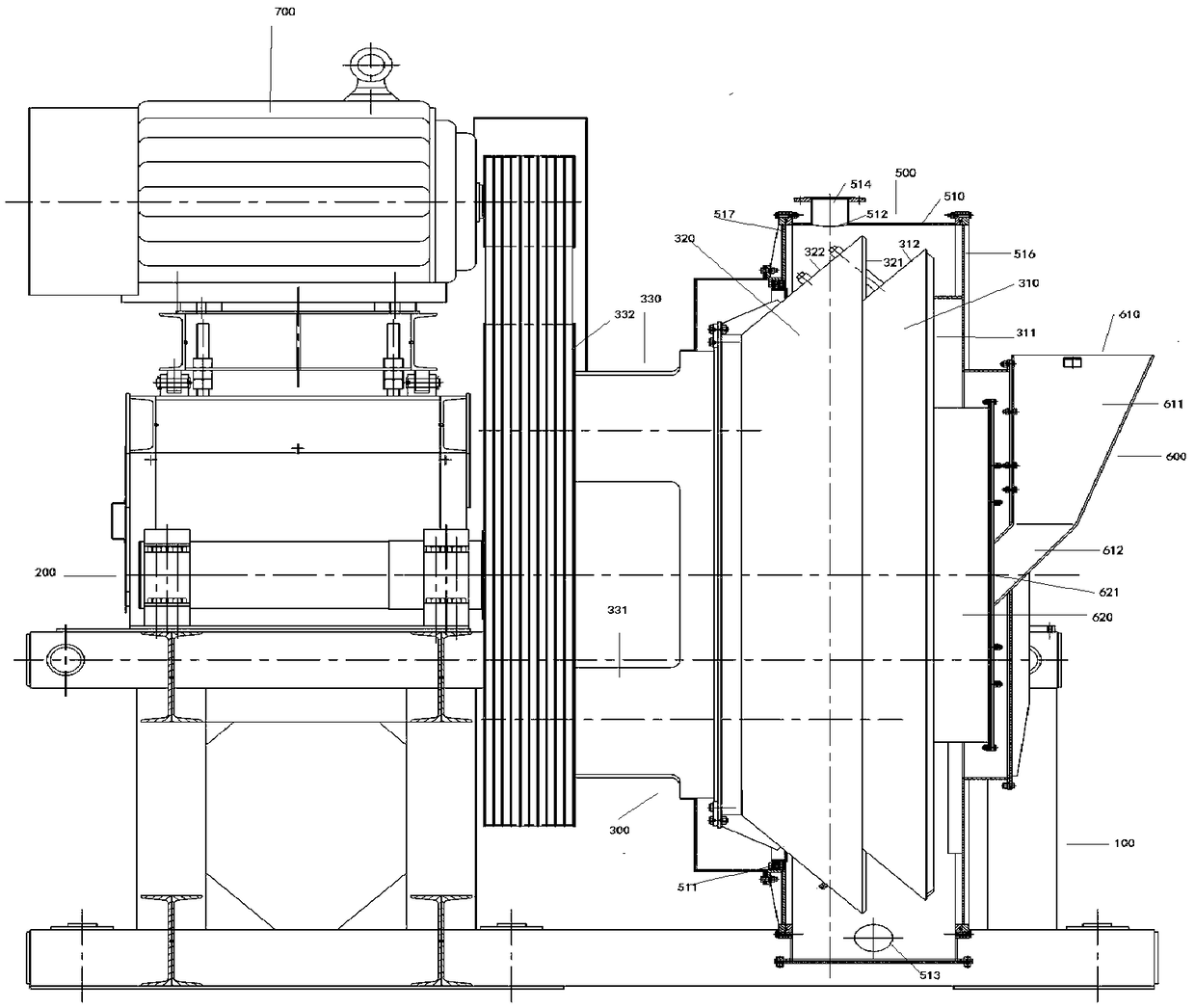

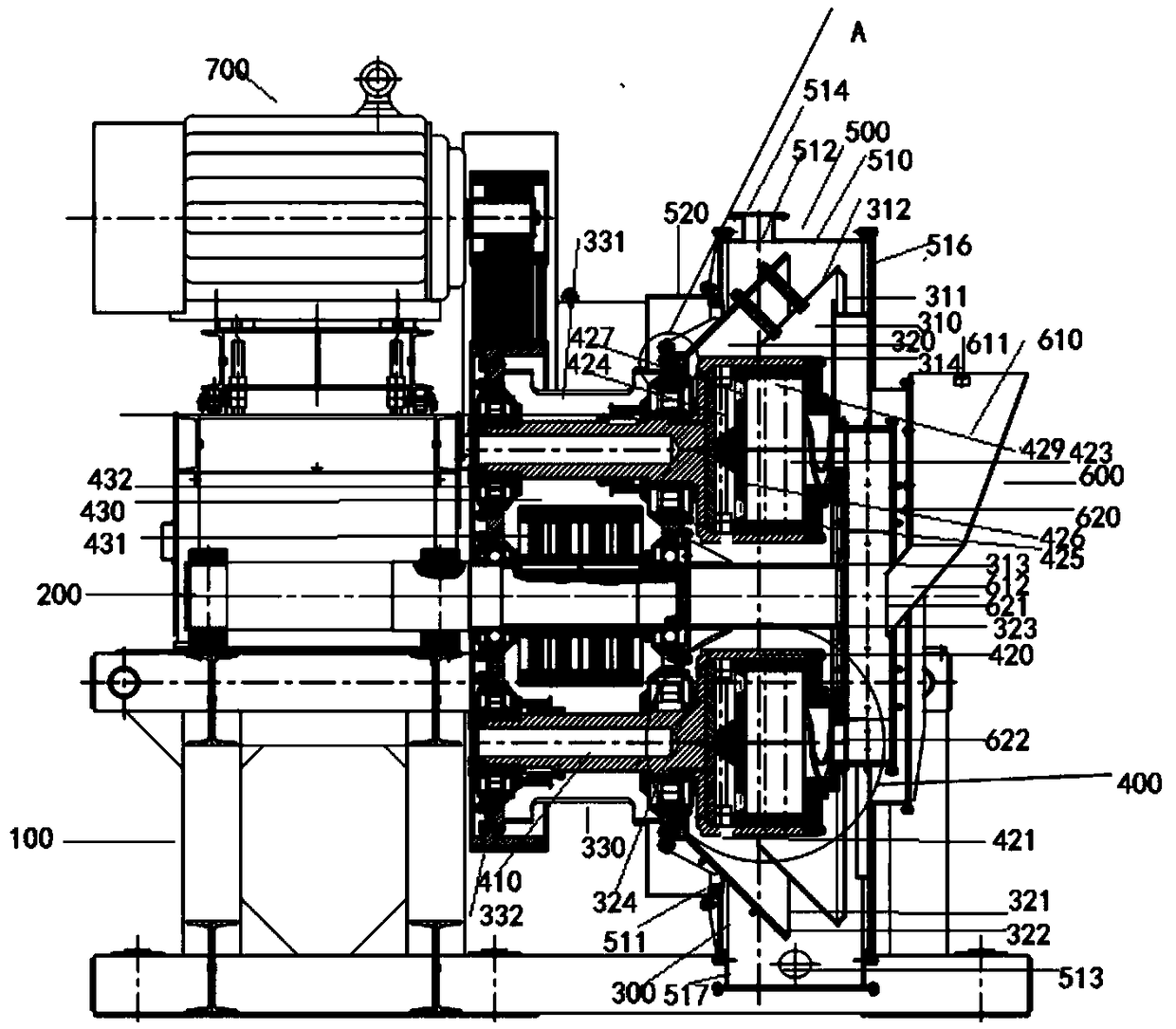

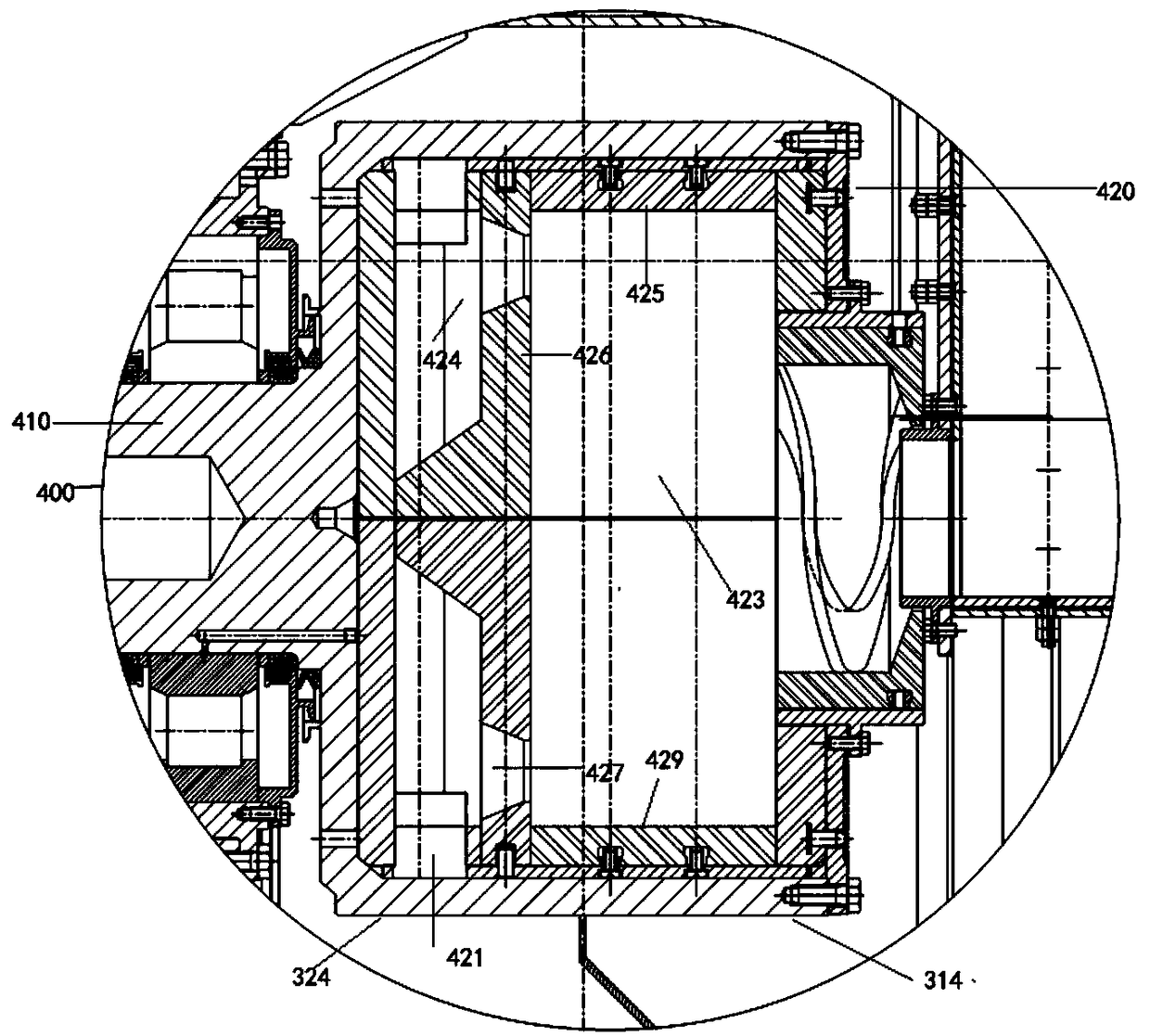

[0037] Such as Figure 1-2 As shown, the discharge device of the planetary ball mill includes: a turntable device 300, which is fixed to the central axis 200 via a pin shaft, including a first turntable 310 and a second turntable 320, and the first turntable 310 includes a first turntable surface perpendicular to the center axis 311 and a first inclined surface 312 located on the edge of the first turntable, the first inclined surface 312 is adjacent to the first turntable surface 311, and the first turntable surface 311 is provided with a first central hole 313 and a plurality of first through holes 314 symmetrical to the center , the first turntable is vertically fixed to the central axis 200 via the first central hole 313, the second turntable 320 includes a second turntable surface 321 perpendicular to the central axis and a second inclined surface 322 positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com