Jaw-replaceable bench clamp

A replaceable jaw technology, applied in vices, manufacturing tools, etc., can solve the problems of low strength, workpiece damage, workpiece displacement, etc., and achieve the effect of firm clamping and prevention of displacement and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention can be explained in detail by the following examples, and the purpose of disclosing the present invention is intended to protect all technical improvements within the scope of the present invention,

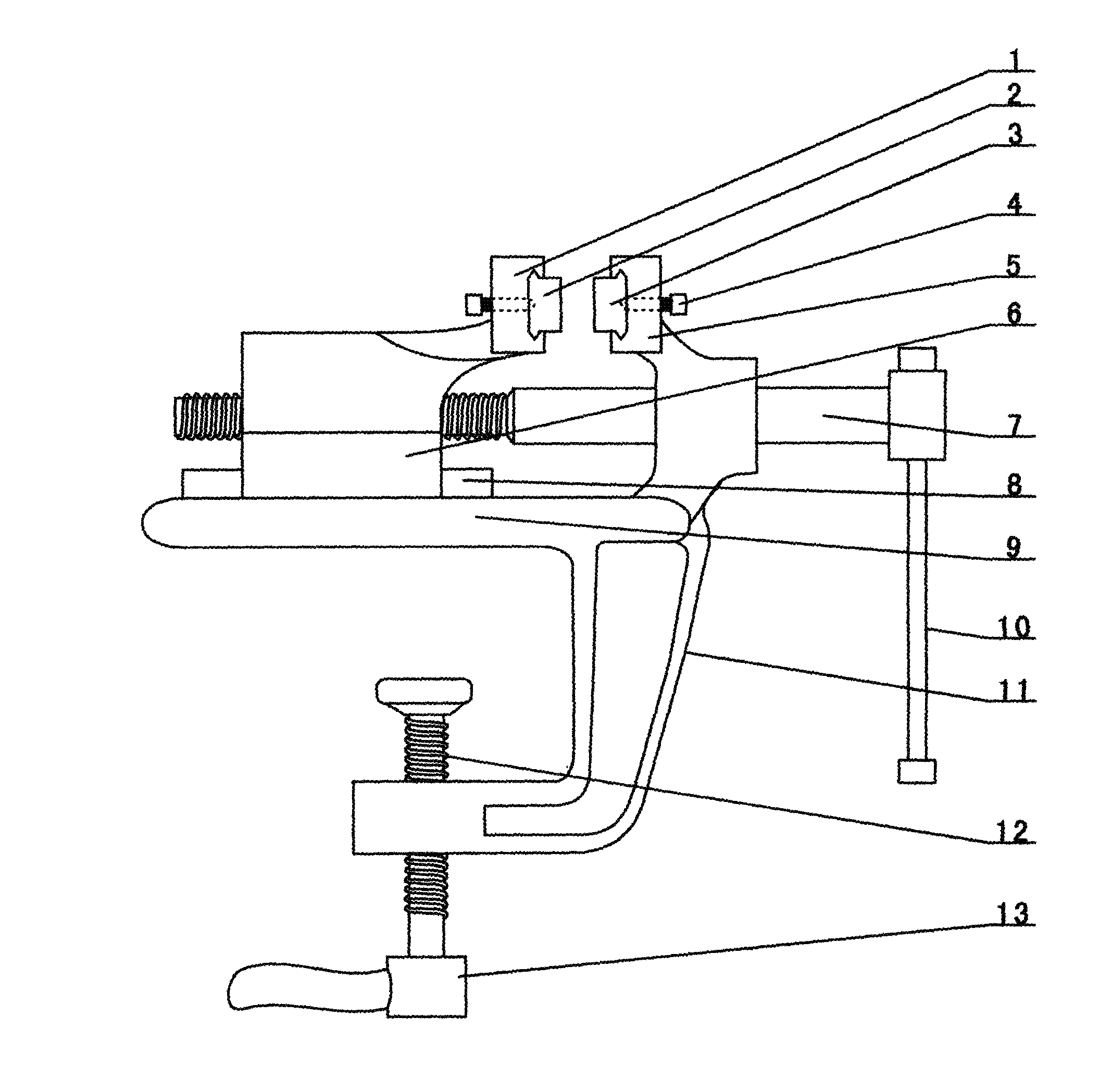

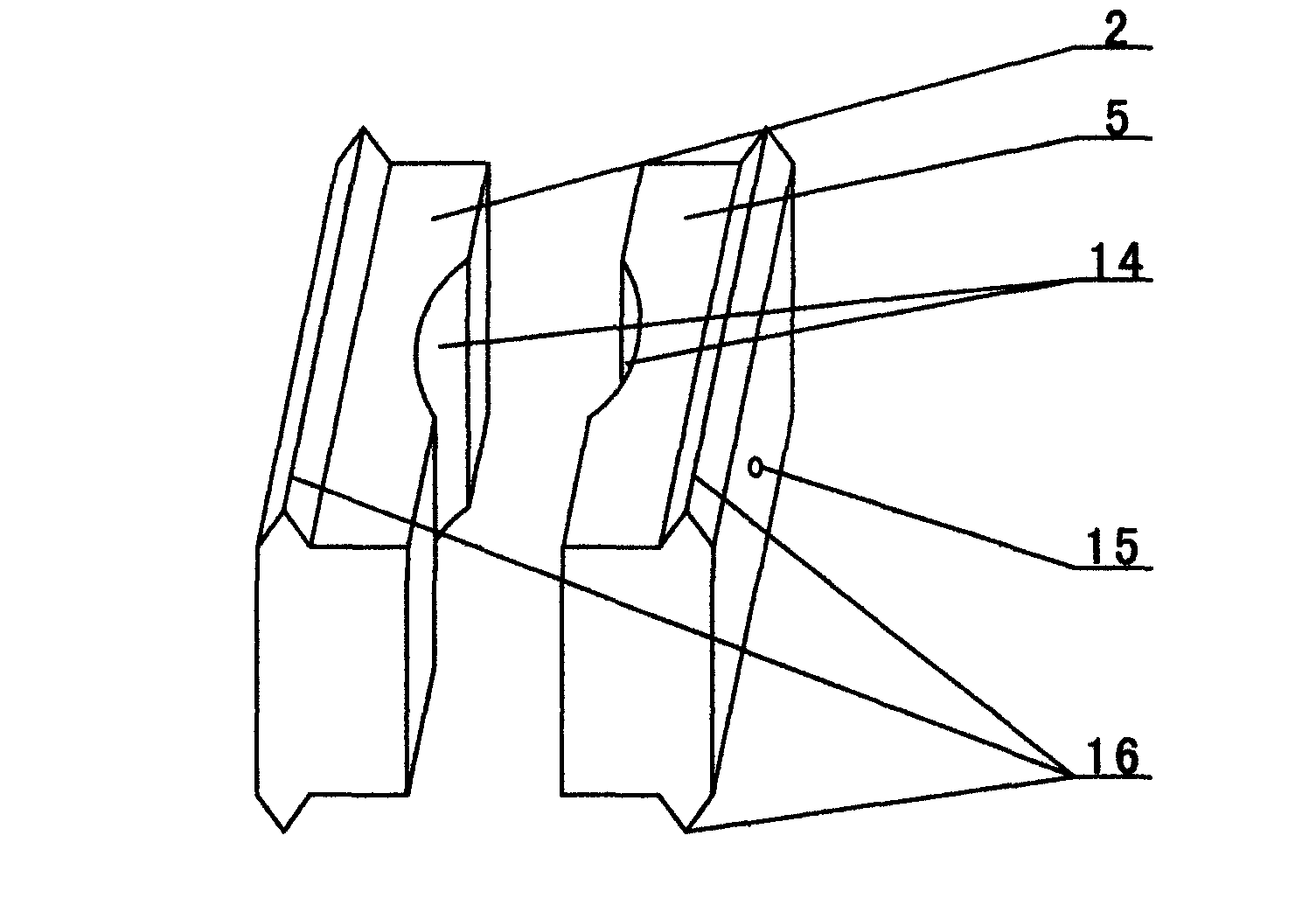

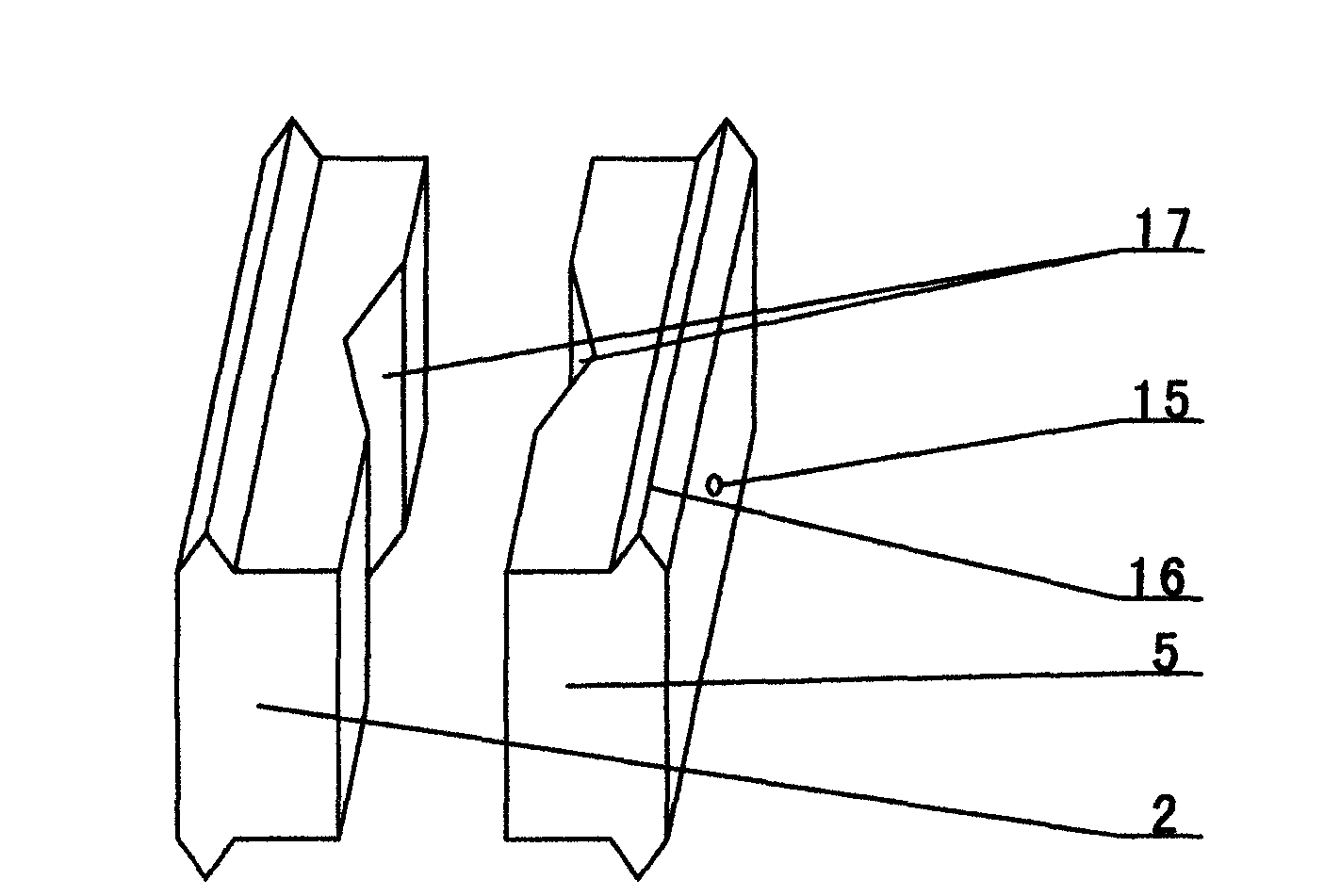

[0019] combined with Figure 1~3 The jaw replaceable vise includes a base 9, a guide rail 8, a fixed clamp body 5, a movable clamp body 1, a locking screw 7, a rotating rod 10, an insert block A2 and an insert block B3. One side is provided with a fixed clamp body 5, and the movable seat 6 at the lower part of the movable clamp body 1 slides and cooperates with the guide rail 8 provided on the other side of the base 9, and the locking screw 7 passes through the middle part of the fixed clamp body 5 and connects with the movable clamp body 1 In the middle part, the end of the locking screw 7 is provided with a rotating rod 10, and the fixed clamp body 5 and the upper jaw of the movable clamp body 1 are respectively provided with horizontally arranged s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com