Press precision cylindrical guide structure

A guiding structure and press technology, applied in the field of presses, can solve problems such as affecting guiding accuracy, reducing stiffness, and difficulty in ensuring position consistency, and achieving the effects of improving guiding accuracy and stiffness, improving connection stiffness, and eliminating over-positioning problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

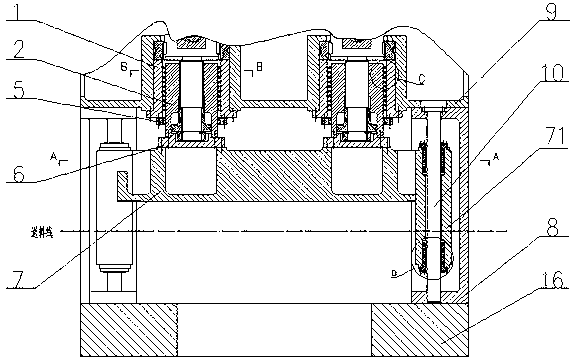

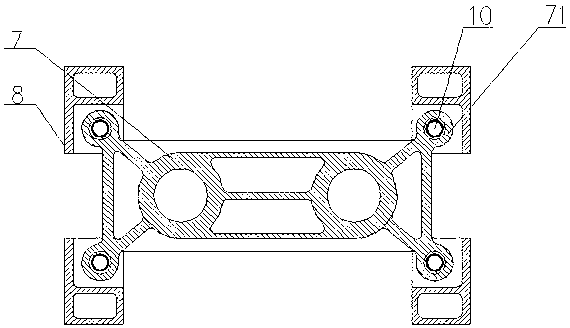

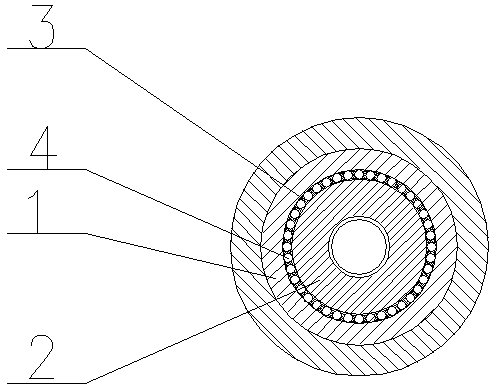

[0019] like figure 1 , figure 2 and Figure 5 As shown, the precision cylindrical guide structure of this press is composed of two parts, the main guide and the auxiliary guide. Column 8, auxiliary guide column 10 and auxiliary guide element; the main sleeve 1 is connected with the upper beam 9 through screws, the lower end of the main column 2 is connected with the upper end surface of the connection plate 6 through screws, and the lower end surface of the connection plate 6 is connected with the slider 7, like figure 1 , image 3 and Figure 4 As shown, between the main column 2 and the main sleeve 1, there is a main guiding element composed of a cage 3 and a ball 4, and the ball 4 is evenly installed in the cage 3 from top to bottom. The diameter of 4 is not less than half of the difference between the inner diameter of the main sleeve 1 and the outer diameter of the main post 2, forming a zero gap or a small interference, and the sealing gland A 5 is connected to the...

Embodiment 2

[0023] This embodiment is basically the same as Embodiment 1, the difference is that, as Image 6 and Figure 7 As shown, the auxiliary guide element is a guide shoe 17, and the guide shoe 17 is installed between the auxiliary guide post 10 and the round table 71 with screws, and is located at the upper and lower ends of the round table 71. There is a small gap between the guide shoe 17 and the auxiliary guide post 10. It is filled with lubricating oil under a certain pressure, and the upper and lower ends of the round platform 71 are provided with a cover 18, which limits the displacement of the guide shoe 17 and prevents the leakage of the lubricating oil. The guiding structure is in surface contact when bearing a load and has good rigidity. Medium press.

[0024] In order to further improve the rigidity of the equipment, the bottom surface of the round table 71 is lower than the feeding line, so that the guiding distance is large, thereby improving the rigidity of the equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com