Novel sliding-type gantry crane and use thereof

A gantry driving and sliding technology, which is applied to the crane of the trolley, the braking device of the hoisting equipment, the load hanging element, etc., can solve the problems of inapplicable substations, cannot be disassembled and cannot be moved while driving, and can ensure the bearing capacity and environmental impact. Small and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions and beneficial effects of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

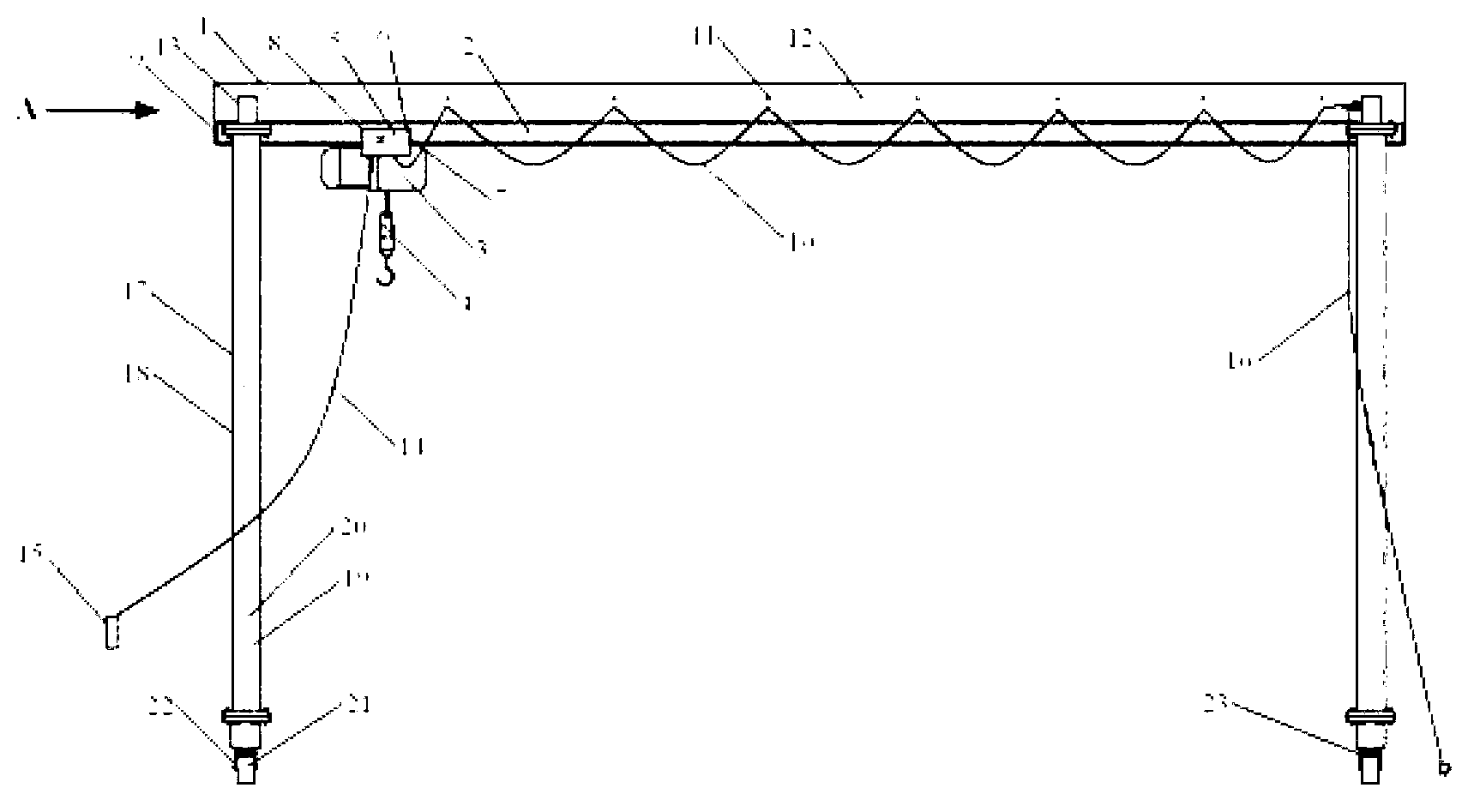

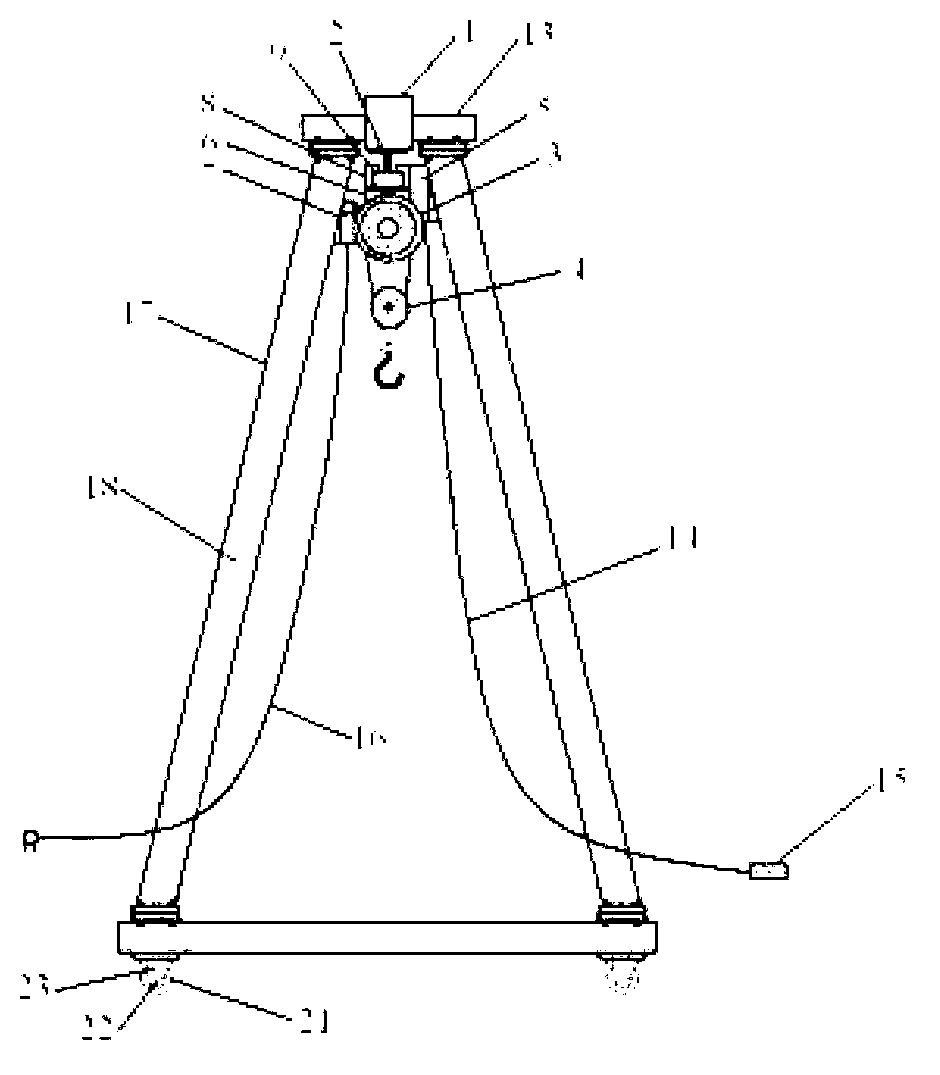

[0032] Such as figure 1 and figure 2 As shown, a new type of sliding gantry crane for GIS installation and maintenance, mainly including main beam 1, support beam 13, top slide rail 2, electric sliding trolley 3, electric chain hoist 4, power supply cable 10, control line 14. Controller 15, triangular bracket 17, roller 21, etc. Wherein, the main beam 1 is arranged transversely in the middle of the gantry crane, and the support beams 13 are arranged longitudinally at both ends of the main beam 1 for supporting the main beam 1 . The top slide rail 2 is welded under the main beam 1, and the electric sliding trolley 3 is suspended below the top slide rail 2 through the cooperation of the trolley running device 8 and the top slide rail 2, and can move along the slide rail 2; the top slide rail 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com