Fence and installation method thereof

A technology for fences and mounting holes, which is applied in the direction of fences, building types, buildings, etc., can solve the problems of time-consuming and laborious installation and disassembly, low recycling rate, damaged parts, etc., and achieve high safety, high recycling rate, and installation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

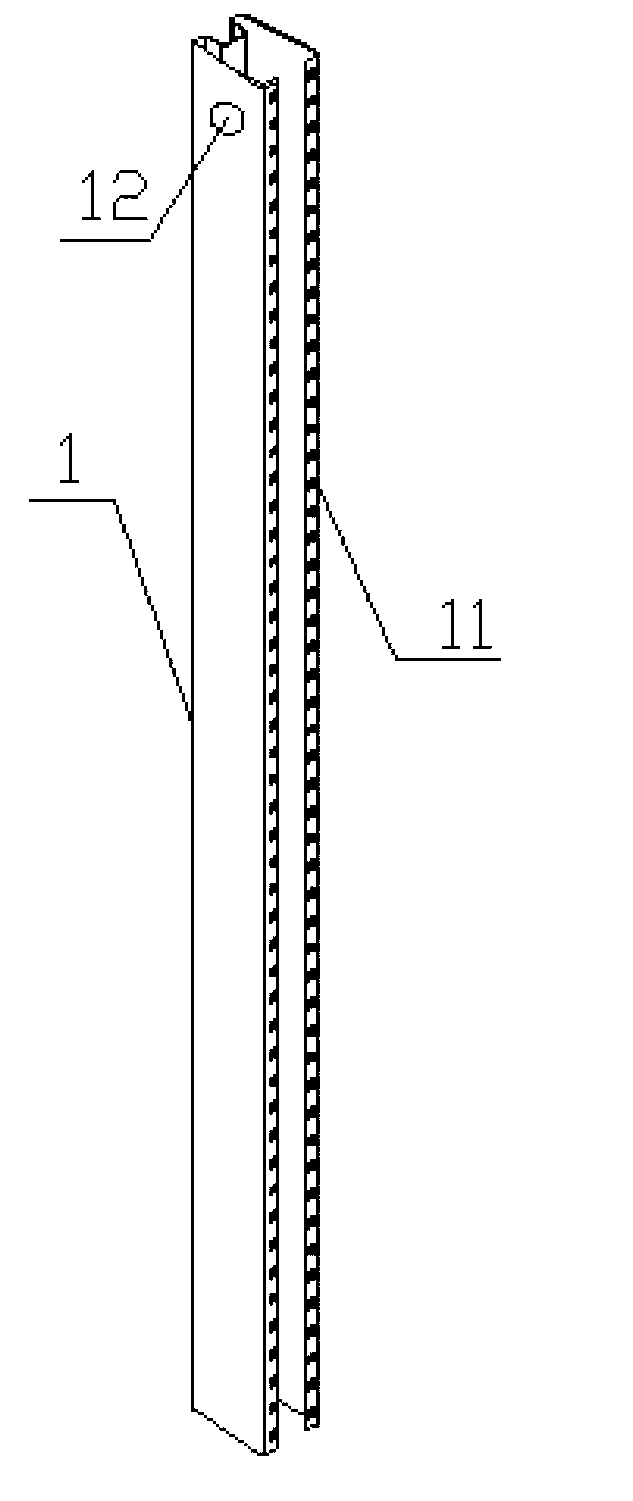

[0042] Such as Figure 8 As shown, 1) Insert two uprights 1 into the ground according to the width of the mesh 5, and the height exposed on the ground is the same as the height of the mesh 5;

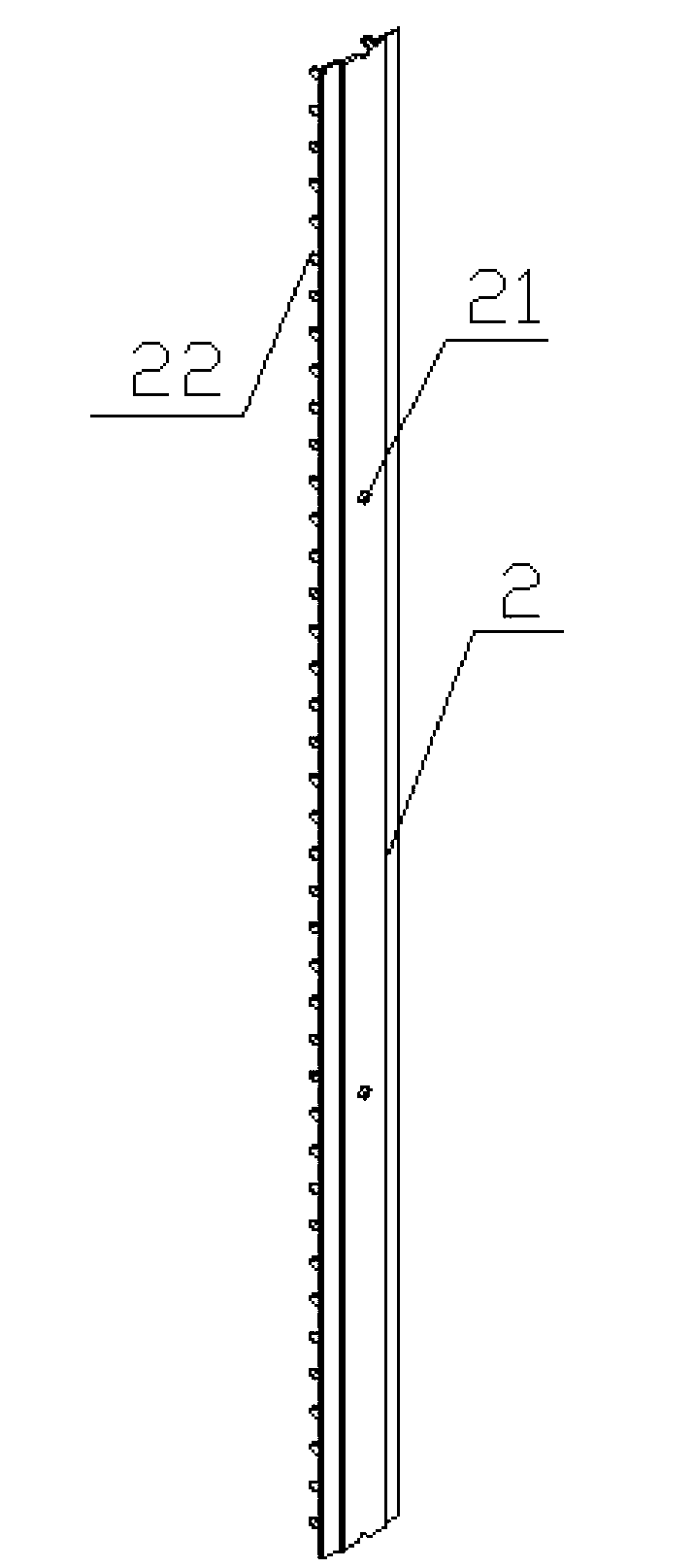

[0043] 2) Disassemble the pressure plate 2 exposed on the ground from the column 1, and keep the pressure plate 2 inserted into the ground;

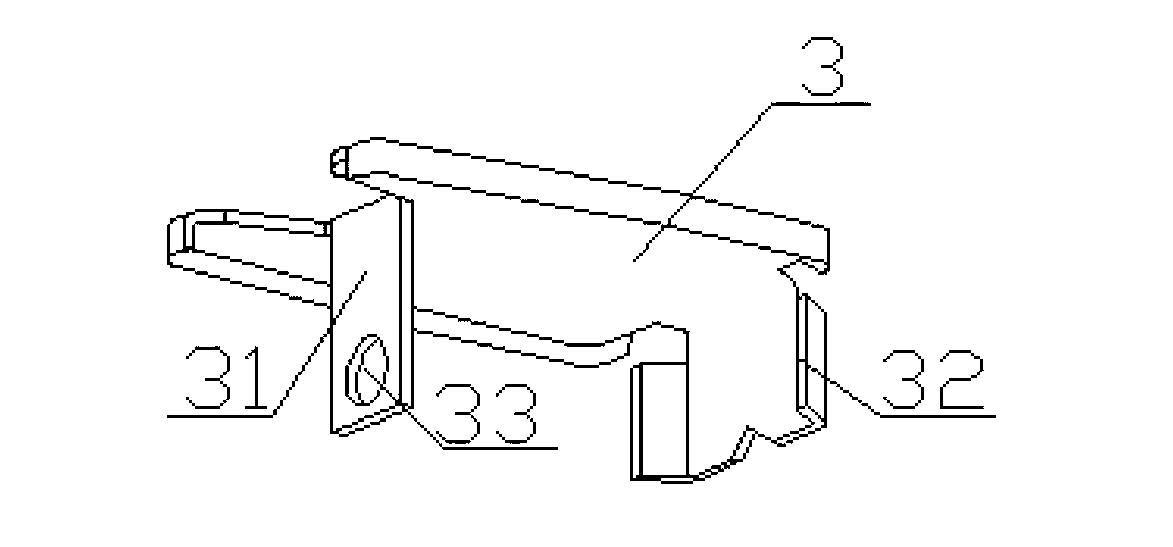

[0044] 3) Install the top cover 3 on the top of the column 1;

[0045] 4) Install the crossbar connector 7 on the left column surface and the right column surface above the column 1 through the bolt one 9 through the fixing hole three 71 and the installation hole 12;

[0046] 5) Install the cross bar 6 between the cross bar connectors 7, and pass the bolt 8 through the fixing hole 4 72 and the fixing hole 2 61 to fix it;

[0047] 6) Paste the mesh 5 between the two columns 1, pass the bolt 8 through the mesh 5 and the second bolt hole 62, and fix the mesh 5 on the cross bar 6;

[0048] 7) Insert the pinion 22 of the pressure plate 2 into the in...

Embodiment 2

[0050] 1) Insert the two columns 1 into the ground according to the width of the mesh 5, and the height exposed on the ground is the same as the height of the mesh 5;

[0051] 2) Disassemble the pressure plate 2 exposed on the ground from the column 1, and keep the pressure plate 2 inserted into the ground;

[0052] 3) Install the crank arm 4 on the top of the column 1;

[0053] 4) Install the crossbar connector 7 on the left column surface and the right column surface above the column 1 through the bolt one 9 through the fixing hole three 71 and the installation hole 12;

[0054] 5) Install the cross bar 6 between the cross bar connectors 7, and pass the bolt 8 through the fixing hole 4 72 and the fixing hole 2 61 to fix it;

[0055] 6) Paste the mesh 5 between the two columns 1, pass the bolt 8 through the mesh 5 and the second bolt hole 62, and fix the mesh 5 on the cross bar 6;

[0056] 7) Insert the pinion 22 of the pressure plate 2 into the insertion hole 11 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com