Lubricating device with warming function

A lubricating device and functional technology, applied in the direction of engine lubrication, lubricating parts, engine components, etc., can solve problems such as oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

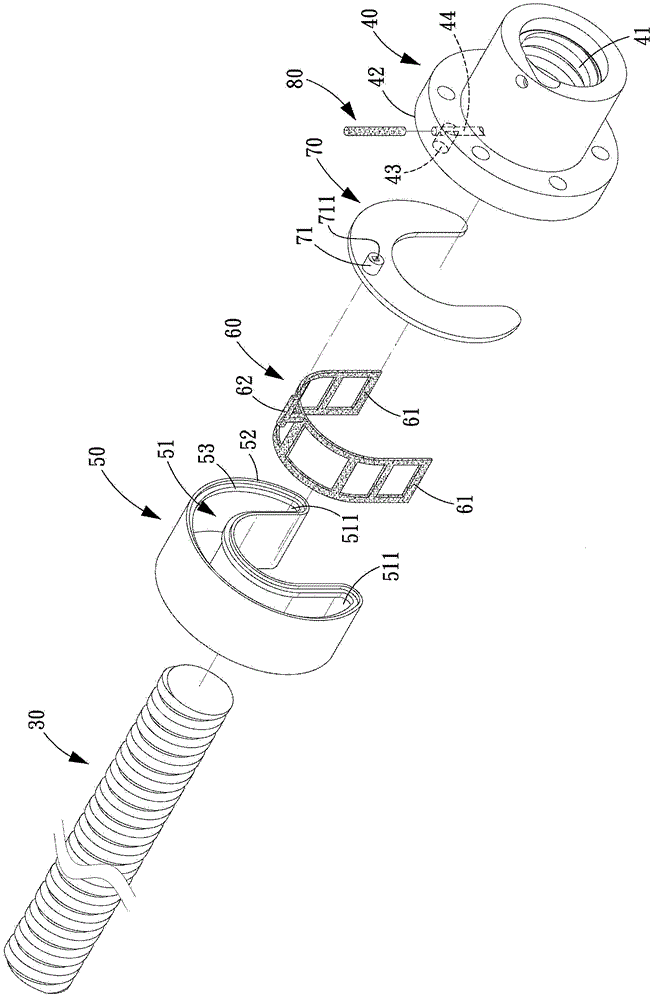

[0058]The preferred embodiment of the lubricating device with temperature increasing function of the present invention is as image 3 , Figure 4 As shown, it is used in conjunction with the long axis 30 and the moving part 40, wherein:

[0059] The lubricating device includes an oil storage tank 50, an oil guide 60 and a heat conduction 70, wherein:

[0060] The oil storage tank 50 has an oil storage space 51 and a port 52 connected to the oil storage space 51 , the inner edge of the oil storage tank 50 forms an abutment edge 53 , and the oil storage space 51 of the oil storage tank 50 has two bottom ends 511 ;

[0061] The oil guide 60 is shaped corresponding to the shape of the oil storage space 51 and has two ends 61 , and the oil guide 60 has a lead-out portion 62 , the oil guide 60 is accommodated in the oil storage space of the oil storage tank 50 51, and make the positions of the two ends 61 of the oil guide 60 correspond to the positions of the two bottoms 511 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com