Control method of industrial process and equipment

An industrial process and control method technology, applied in the directions of adaptive control, general control system, control/regulation system, etc., can solve the problems of large value span, unfavorable controller design, difficulty in selecting controller error weight coefficient parameters, etc. , to achieve the effect of simple and intuitive adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

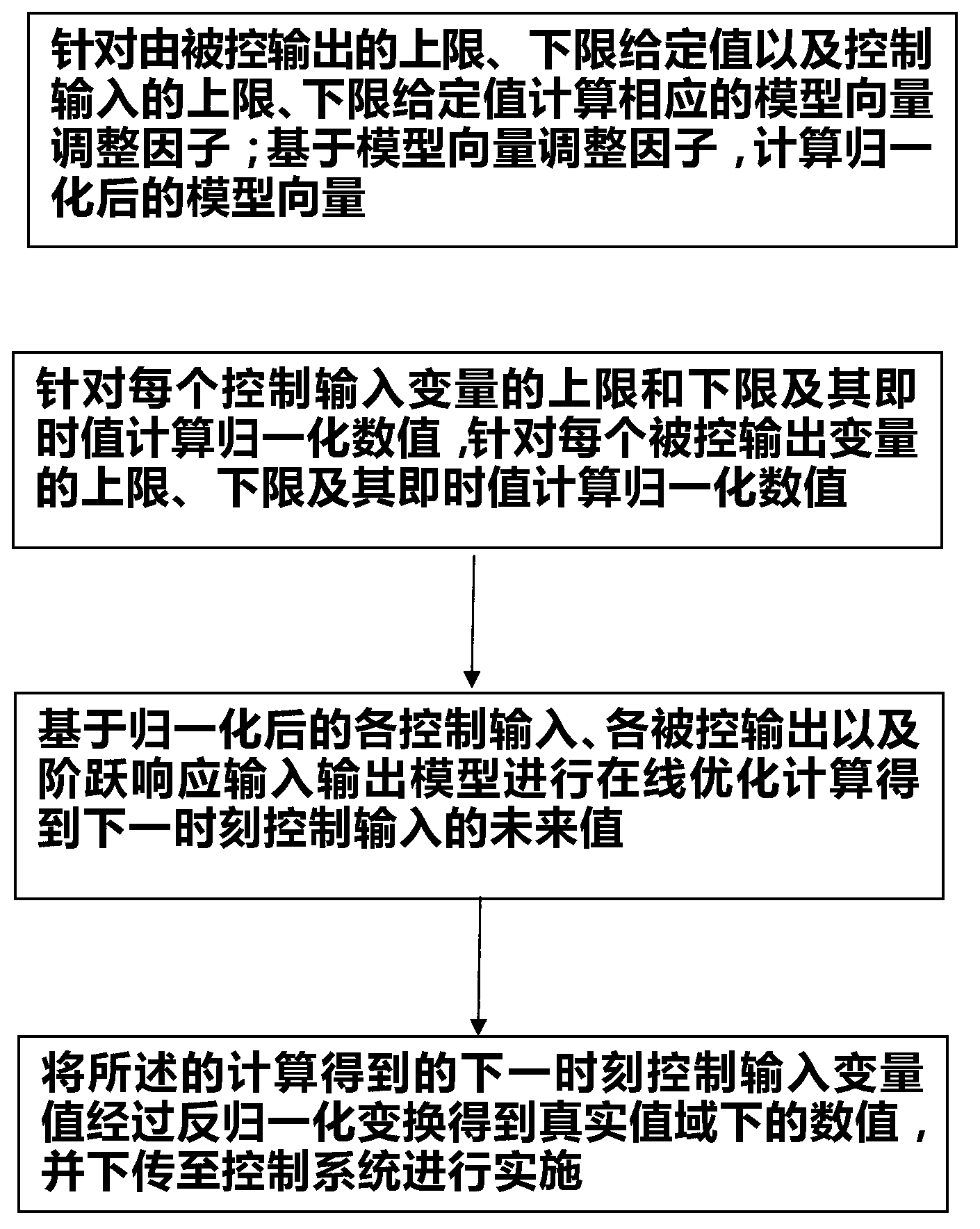

[0057] The specific embodiments of the present invention will be described in detail below in conjunction with the drawings.

[0058] For the convenience of description, the input and output variable definition symbols before normalization are expressed in capital letters, and the input and output symbols after normalization are still expressed in lowercase letters; the step response input and output model vector before normalization is defined as .

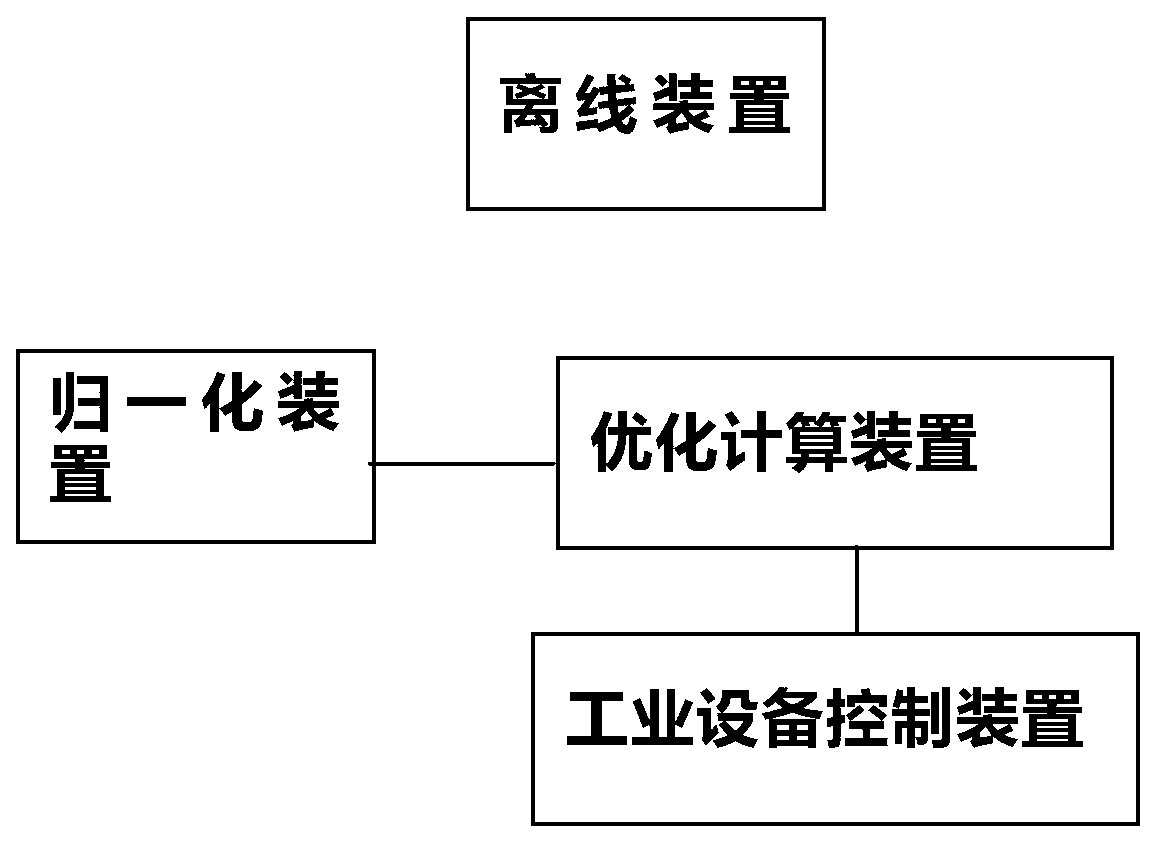

[0059] The invention relates to two main modules, offline and online.

[0060] 1. Offline module

[0061] The upper limit of the controlled output , Lower limit And control input range , Calculate the corresponding model vector adjustment factor ,specifically,

[0062]

[0063] by The normalized model vector can be further calculated . specifically,

[0064]

[0065] among them, It is a process step response model identified based on the input and output data before normalization.

[0066] 2. Online module

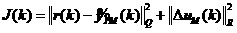

[0067] (a) Before optimi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com