Pricking rod dead weight type eggshell hole pricking machine and pricking rod dead weight type eggshell hole pricking method

A piercing machine and piercing rod technology, which is used in household appliances, food preparation, food science, etc., can solve the problems of inability to guarantee the same quality and effect of piercing, low efficiency, labor and time consuming, etc., and achieve piercing effect. Stable and efficient, consistent piercing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

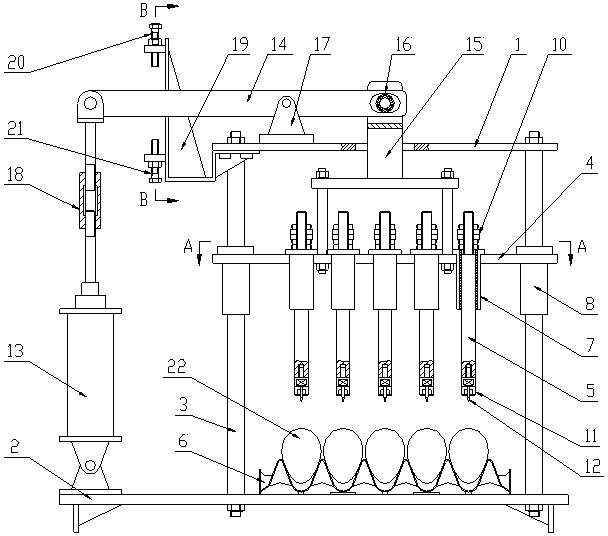

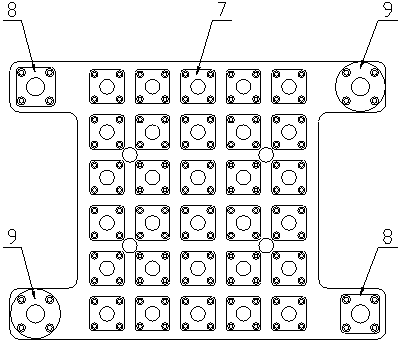

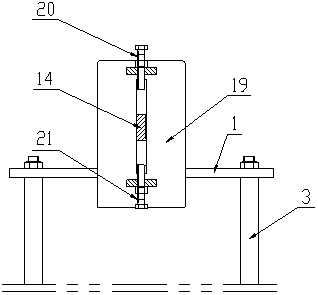

[0021] Such as Figure 1~3 As shown, a self-weight eggshell piercing machine with thorn rods includes a frame, and the frame is provided with a lifting pallet 4, and 30 weights and initial heights can be adjusted on the lifting pallet 4. The movable stabbing rod 5, the movable stabbing rod 5 performs approximate free fall motion when the lifting pallet 4 rapidly descends with an acceleration greater than the acceleration of gravity, and a raw egg standing device is arranged below the movable stabbing rod 5, and the raw egg The egg standing device is an egg tray 6, and the egg tray 6 is provided with thirty egg troughs respectively corresponding to each movable prod 5, when the raw egg 22 is placed vertically, the big end faces upwards and the small end Downward, the simultaneous piercing process of thirty eggs can be completed at one time. Of course, the laying egg vertical laying device can also be a laying egg vertical laying conveyor belt, or the egg tray 6 is placed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com