Entitative coal seam gas drainage drilling hole double-pipe drainage method

A drainage drilling and gas extraction technology, which is applied in the fields of gas discharge, mining equipment, earthwork drilling, etc., can solve problems such as restricting the development of coal and gas co-mining technology, difficulty in effectively extracting gas, and low gas drainage flow rate , to achieve wide practicability, convenient operation, and improve the effect of gas drainage flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings:

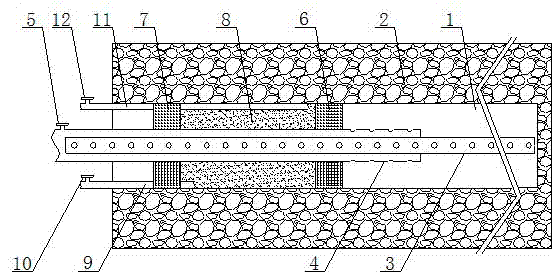

[0014] like figure 1 Shown, this coal seam gas drainage borehole double-pipe extraction method of the present invention: at first in this coal seam drill field to coal body 2 by conventional construction a gas drainage borehole 1, the hole depth of gas drainage borehole 1 and The hole diameter is determined according to the actual situation on site, for example, the hole depth is 70m, and the hole diameter is 113mm; The eyelet is connected according to the plug-in method and sent to the bottom of the drainage borehole 1. A flexible sleeve 4 is installed at the rear of the gas drainage pipe 3. The diameter of the flexible sleeve 4 is twice the diameter of the gas drainage pipe 3. The flexible sleeve The front end of the tube 4 is provided with a 3-4m blind; at a position 4-5m away from the front end of the flexible casing 4, the polyurethane double-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com