Carbon dioxide gas suction and separation device and method of mixed working medium circulation system

A carbon dioxide, circulating system technology, applied in separation methods, chemical instruments and methods, steam engine installations, etc., can solve the problems of not meeting storage requirements and high energy consumption, and achieve the improvement of ejection ratio and work efficiency, and reduction of energy consumption and lower energy consumption. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

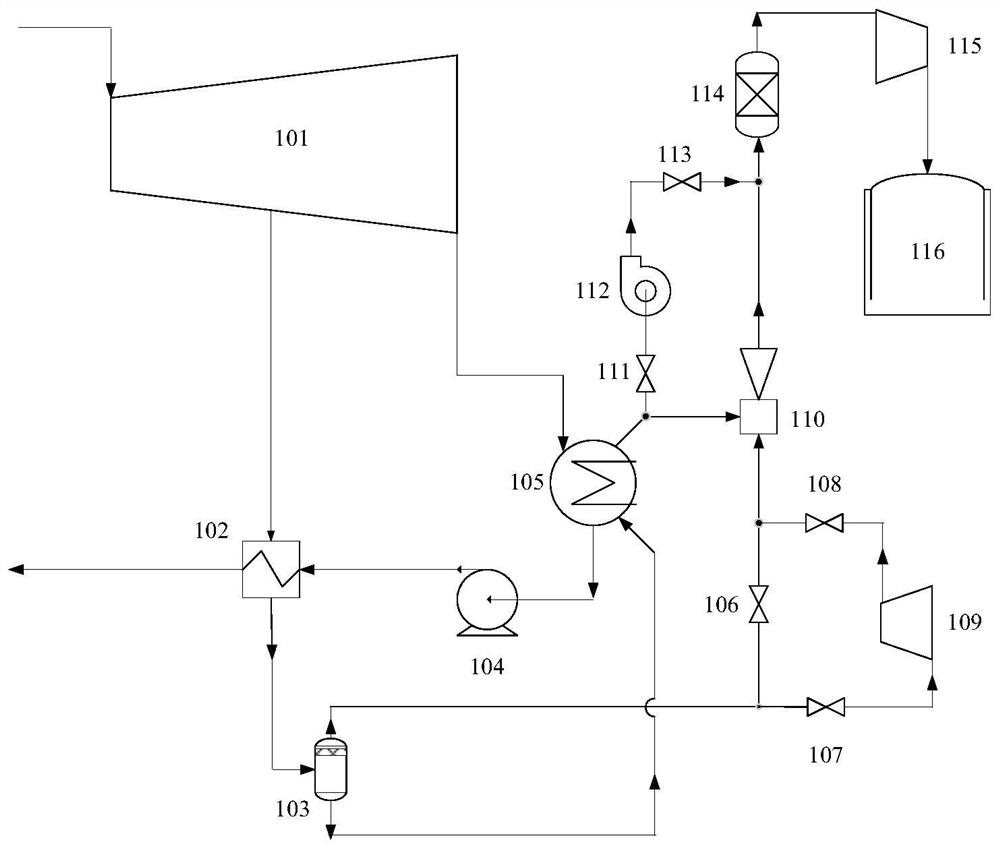

[0039] A carbon dioxide gas suction and separation device for a mixed working medium circulation system according to an embodiment of the present invention, the steam extraction outlet of the steam turbine 101 is connected to the hot fluid inlet of the feed water heater 102, the outlet of the steam turbine 101 is connected to the inlet of the condenser 105, and the condensate pump The inlet of 104 is connected to the liquid outlet of condenser 105, the cold fluid inlet of feed water heater 102 is connected to the outlet of condensate water pump 104, the inlet of gas-liquid separator 103 is connected to the outlet of hot fluid of feed water heater 102, the liquid outlet of gas-liquid separator 103 is connected to the outlet of condensate pump 104 The inlet of the vaporizer 105 is connected, the high-pressure inlet of the ejector 110 is connected with the outlet of the gas-liquid separator 103, the low-pressure inlet of the ejector 110 is connected with the gas outlet of the conde...

Embodiment 2

[0042] In this embodiment of the present invention, the difference from Embodiment 1 is that a centrifugal compressor is connected in series before the high-pressure inlet of the ejector. When the suction device is working, open the centrifugal first inlet valve and the centrifugal first outlet valve, and close the bypass valve. The centrifugal compressor increases the gas pressure at the outlet of the gas-liquid separator to 1500kPa, the injection coefficient of the ejector can be increased by 35%, and the suction flow rate of the ejector to the carbon dioxide in the condenser can be increased by 14%.

[0043] In embodiment 1, the compressor and the inlet and outlet valves of the compressor are closed, and the bypass valve is in an open state. When the steam extraction pressure of the steam turbine is high, no additional power consumption is required to achieve the purpose of energy saving; in embodiment 2, the compressor and the compressor The inlet and outlet valves are ope...

Embodiment 3

[0046] The difference from Embodiment 1 is that a centrifugal compressor is connected in series before the high-pressure inlet of the ejector, and a centrifugal fan is connected in parallel between the low-pressure inlet and the outlet of the ejector. When the suction device is working, open the first inlet valve and the first outlet valve, close the bypass valve, and open the inlet and outlet valves of the centrifugal fan at the same time. The centrifugal compressor increases the gas pressure at the outlet of the gas-liquid separator to 1500kPa, the injection coefficient of the ejector can be increased by 35%, and the suction flow rate of the ejector to the carbon dioxide in the condenser can be increased by 14%. Utilizing the auxiliary suction effect of the centrifugal fan, the suction flow rate of the suction device for the carbon dioxide in the condenser can be further increased by 30%.

[0047] According to the above-mentioned embodiments of the present invention, the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com